OD1ES RILERS

Page 40

Page 41

If you've noticed an error in this article please click here to report it so we can fix it.

Construction industry, as expectn embracing 44-tonners with enthusiasm weights uplift has increased capacities I a typical 54yd3 (41.3m3) trailer at 38 tel COW to 61-64 yd3 (452-490) at 44 tonne TIPPer operators are having to inve: remain competitive, says Angus Spo: general manager. tippers, at Gen Trailers, and running costs per tonne of load at 44 tonnes are substantially Ii than they are in a 32 or 38-tonne 8x4, the same If not better manoeuvrability.

Short wheelbase

Most tipping trailers have a short wl base, which makes meeting turning c requirements more difficult. Tippers go ally need to have 10.5-11m bodies to meet requirements, so check if you are plan to uprate existing trailers.

Trailer designs must allow a relat long overhang of body in front of the kin or the operator risks putting toe I weight through the drive axles while o loading the trailer bogie. "We believe best solution is to have a recessed mounting inside the body front bulkhc says Spooner. "Other solutions potent involve extra weight."

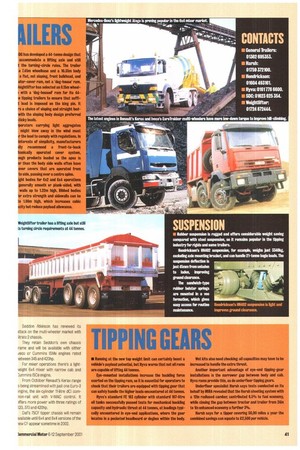

DC has developed a 44-tense design that. accommodate a lifting axle and still I the turning-circle rules. The trailer a 7.45m wheelbase and a 10.35m body a flat, not sloping, front bulkhead, and uter-cover ram, not a 'dog-house ram. leightlifter has selected an 8.15m wheel: with a 'dog-housed' ram for its 44e tipping trailers to ensure that suffi

t load is imposed on the king pin. It 's a choice of sloping and straight hodwith the sloping body design preferred ticky loads.

parators carrying light aggregates might blow away in the wind must r the load to comply with regulations. In interests of simplicity, manufacturers illy recommend a front-to-back lianically operated cover system, High products loaded so the apex is ay than the body side walls often have over covers that are operated from to side, passing over a centre spine.

ight bodies for 6x2 and 6x4 operations generally smooth or plank-sided, with walls up to 1.22m high. Ribbed bodies er extra strength and sidewalls can be s 198m high, which increases cubic laity but reduce payload allowance.