LOOK WHAT WE FOUND!

Page 48

Page 49

Page 50

Page 53

If you've noticed an error in this article please click here to report it so we can fix it.

The gallery at the Commercial Motor Show at Earls Court is always packed with interesting accessories, components and servicing equipment, but even the keenest operator finds it a daunting task to seek out the new and the novel from among 200-odd stands. This year CM followed up its preview of these exhibits (September 13 issue) by sending six staff members into the gallery to ask, "What's new?" on 217 stands. As this report reveals they found plenty of new or interesting exhibits which had not previously been described.

by Tony Wilding

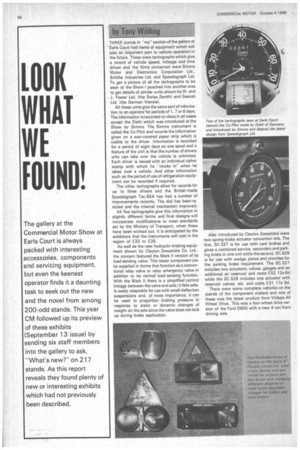

THREE stands in "my" section of the gallery at Earls Court had items of equipment which will play an important part to vehicle operation in the future. These were tachographs which give a record of vehicle speed, mileage and time driven and the firms concerned were Simms Motor and Electronics Corporation Ltd., Smiths Industries Ltd. and Speedograph Ltd. To get a picture of all the tachographs to be seen at the Show I poached into another area to get details of similar units shown by W. and J. Foster Ltd. (the Swiss Zenith) and Geecen Ltd. (the German Kienzle).

All these units give the same sort of information to an operator for periods of 1, 7 or 8 days. The information is recorded on discs in all cases except the Diehl which was introduced at the Show by Simms. The Simms instrument is called the Co-Pilot and records the information given on a wax-covered paper strip which is visible to the driver. Information is recorded for a period of eight days on one spool and a feature of the unit is that the number of drivers who can take over the vehicle is unlimited. Each driver is issued with an individual cipher stamp with which he "clocks in" when he takes over a vehicle. And other information such as the period of use of refrigeration equipment can be recorded if required.

The other tachographs allow for records for up to three drivers and the British-made Speedograph Tac-824 has had a number of improvements recently. The dial has been restyled and the internal mechanism improved.

All five tachographs give this information in slightly different forms and final designs will incorporate modifications to meet standards set by the Ministry of Transport, when these have been worked out. It is anticipated by the exhibitors that the instruments will cost in the region of £33 to £35.

As well as the new hydraulic-braking equipment shown by Clayton Dewandre Co. Ltd., the concern featured the Mark II version of its load-sensing valve. This latest component can be supplied in forms that function as a conventional relay valve or relay emergency valve in addition to its normal load-sensing function. With the Mark II there is a simplified control linkage between the valve and axle: it fails safe, is easily adaptable for use with small deflection suspensions and, of most importance, it can be used to proportion braking pressure in response to static or dynamic changes of weight on the axle since the valve does not lock up during brake application. Also introduced by Clayton Dewandre were two spring-brake actuator convertion kits. The first, SC.527 is for use with cam brakes and gives a combined service, secondary and parking brake in one unit while the second, SC. 528 is for use with wedge plates and provides for the parking brake requirement. The SC. 527 includes two actuators, valves, gauges and an additional air reservoir and costs £52 12s 6c1 while the SC.528 includes one actuator with reservoir valves, etc. and costs £31 17s 6d.

There were some complete vehicles on the stands of the component makers and one of these was the latest product from Vickers All Wheel Drive. This was a four-wheel drive version of the Ford 0800 with a new 4-ton front driving axle. Other important exhibits in this section of the gallery were on the Dunlop stand with the latest Maxeret anti-locking system and new Stabilair air suspension. And the company also had other air suspension developments with the introduction of rolling-diaphragm type air springs for p.s.v. use and larger types of its normal product.

Flexible Lamps Ltd. was showing new Rubbolite units developed for use on the latest Leyland trucks and there were also prototypes of new trailer rear lamps incorporating large reflecting triangles. One of these has as its main feature the elimination of all screws for the lens and fixing. It also has a new method of cable entry designed to reduce the chance of water entry and like the unit based on an existing Rubbolite lamp will meet proposed regulations for all trailers and semi-trailers to carry a pair of triangles expected to come into force in 1970.

To complete the items seen which were not included in previous issues of CM. General and Industrial Paints Ltd. showed its new Gipspeed quick-drying synthetic paint, Hills IPatents) Ltd. its Vari-Wype windscreen-wiper control which allows a driver 10 different wiping frequencies and John Perks and Son (Forgings) Ltd. showed a revised range of container fittings, including hinges, made from rolled steel to give lightness and the prototype of anti-rack container-door locking gear in which the top and bottom locking cams locate with pegs on the cam brackets.

by Derek Moses

A DEVELOPMENT of the Telma electric retarder is the Focal-type which was shown by Telma Retarder Ltd. The Focal retarder has been designed for use in underfloorand rear-engined passenger chassis, and in tractive units, where the prop-shaft is of very limited length. Unlike previous Telma retarders. the Focal-type can be coupled directly to the gearbox output shaft or to the differential.

An added advantage of the Focal retarder is that it has no bearings of its own and is therefore maintenance free, unlike the earlier type which has to be periodically greased. A prototype has been on trial for about 15 months in an underfloor-engined Guy Victory with Gardner 6H LX engine operated by the Cooper Car Co. Ltd. as a racing car transporter, and has been completely successful.

A new lightweight pump for automatic discharge duties has been developed by Drum Engineering Co. Ltd., in conjunction with

Alfons Haar. Hamburg, giving up to 85 gal/ min at 1,000 rpm against pressures up to 85 Ibiin2 and has a speed range of 600-1,600 rpm. Using 24 d.c. drive the new pump will give 30 per cent higher output.

Another Drum development is a footmounted gearbox developed to meet tanker problems arising from the wide variation in gearbox take-off speeds. The box will provide a step-up and step-down drive to pumps, compressors, and so on in static installations and on tankers. Continuous rating at the output shaft is 20 bhp at 1,500 rpm. The maximum shaft speed, for eight-hour rating. is 2,000 rpm giving 24 bhp, Two members supporting the thighs and the back of the knees and which can articulate independently are features of the cushion of the Silhouette driver's seat introduced by the automotive division of Hallam. Sleigh and Cheston Ltd. for commercial and passenger vehicles. Its aim is to give individual leg support and to overcome the problems of stress and strain.

Individual controls provided for each leg support are a spring tension control to cater for adjustment to meet individual weights and a height limit control to allow easy ingress and egress for each support. Provision is also made of a squab rake adjustment which fully complies with DIN specifications. The whole seat unit is provided with 4in. forward and aft movement and similar vertical movement.

The Almex ticket machine with audit strip can now, in the nine-keyband model, be supplied with a magnetic tape and examples were shown by Almex Ticket Machine Co. Ltd. The tape provides innumerable facilities for analyses on which traffic plans can be based. A twochannel system makes the machine selfchecking, ensuring a high degree of reliability. The entire cash accounting can be done automatically by data processing. When the cassette, which contains tape for some 2,000 recordings, is full, the machine is blocked. In the Almex converter the magnetic tape is wound back to starting position and can be used again. The ticket roll suffices for 500 tickets and the machine, which can be carried or mounted on a stand, can be manually or electrically driven. The tape can be used in conjunction with an Almex magnetic reader type 501.

A hopper window which can be slotted into the glass of a bus window is the Derwent, manufactured by Beckett, Laycock and Watkinson. The window can be supplied in two widths, 750mm (29.527in.) or 1,000mm (39.370in.) and an advantage of the Derwent hopper is that it can be fitted to most p.s.v. windows irrespective of the length of the bay.

Another unit which can be similarly mounted was also shown. This is the Medway sliding unit which is a two-way slider with locking catches.

A high-speed seal of silicone rubber for the rear-end of crankshafts was shown by Charles Weston and Co. Ltd. Seals of this type are already being used on Dorman engines.

In addition to normal wheel balancing weights, a new weight for Continental-type wheels, such as those manufactured by Michelin, has been developed by Airvert Ltd. Known as the Series 0014, the new weights are specifically designed for light vans having half-circular rolled rims.

by Ron Cater

A TRIP around my section of the gallery which was devoted to transport service equipment brought to light several items which had been introduced for the Show. Among the interesting units I saw were a fuel pump test bench, garage hose dispensing reel, jig for cracktesting cylinder heads and a kit designed to maintain tyre pressures while a vehicle is in motion.

The cylinder head testing jig was shown by an Australian company, the Repco Automotive Equipment Co. Pty. Ltd. It comprises a fabricated steel stand carrying a framework arranged to be mounted on spindles so that it can revolve on a horizontal plane. This section of the device is made from square box-section material and one of the longitudinal members is arranged as a sliding unit permitting the framework to accommodate varying sizes of cylinder head.

In use, the head to be tested is mounted in the frame and secured by hook clamps and cross-bars. All the apertures in the head which connect with the water passages are then blanked off with a series of clamps secured to the framework by U-shaped strips of flat steel, slotted to take an arm carrying a rubber-faced pad. This pad is mounted on the sliding arm through a clamp screw and is positioned over the aperture to be covered and screwed down tight. The tension on the sliding arm locks the U-strip around the square framework and holds it in position.

Compressed air from the garage air supply is introduced into the casting via a snap connector, and an air gauge is included from which any pressure drop due to leakage and, therefore cracks in the casting, can be ascertained. The actual location of the leak is determined by sound or the use of soapy water according to its severity, Apaseal Ltd. showed the Schrader tyre pressure maintenance system for trailers which by using a newly developed plastics seal enables air pressure to be carried from a stationary component to one that is revolving. The system incorporates a control box which houses a pressure regulating valve, a pressure switch and a pair of standard 996 dry batteries.

Air is collected from the emergency line of the braking system and fed through pipelines which are located within the axle tubes and which feed out through the stub-ends into the pick-up unit contained in the hub-bearing cap and thence to the tyre valve. Pressure is maintained at the required level by the regulating valve, while the pressure switch causes the alarm signal to activate in the event of pressure dropping below a predetermined level.

Side advantages claimed for the unit are that the seal is designed to collapse under excessive heat and to fracture through excessive side or end movement so that both these conditions which can easily occur in a hub assembly, will cause the alarm to activate.

The Merlin Engineering Co. Ltd. showed the Calimaster fuel pump test bench which can be supplied in either mechanical or hydraulically driven form having eight or 12-cylinder testing units. The Calimaster has a wide range of spindle speeds in its two forms.

The mechanical model will operate at speeds of 45 to 600 rpm and 350 to 5.000 rpm while powered by a 50-cycle motor, and 50 to 725 rpm and 480 to 6,000 rpm on a 60-cycle motor. The hydraulic models have spindle speeds of 0 to 1,300 and 0 to 5.000 rpm.

Separate fuel outlets are provided, one at high pressure for phasing and the other at low pressure for calibrating. A shot-counting system is provided and this, operated by a series of solenoids, selects up to 2,000 injections in increments of 100 shots.

A hose reel shown byJAR Garage Equipment incorporates a spring motor rewind mechanism and a framed-roller guide unit which allows the hose to be wound on or off the reel in a controlled manner no matter in which direction it is pulled or allowed to run back. The gland between the static pipework and the revolving drum is covered by a quickly detachable cover which when removed exposes the complete mechanism for servicing.

The spring motor is covered by a similar cover but this incorporates the anchor point for the spring and is so designed that spring tension can be increased or decreased as required by repositioning the casing. A snap air-coupling is provided and the wall bracket is designed to allow the reel assembly to be removed and stored in a safe place outside working hours. The reel will accommodate approximately 50ft of 3/16in, bore hose.

by Paul Brockington

A TWIN-ALTERNATOR installation, a thermostat tester and an electronic petrol-injection system—these were among the components of engine or engine-equipment interest that makers displayed or revealed in the section of the gallery which I covered at Earls Court. Further details were obtainable later in the Show of the use of an exhaust driven turbo charger for supplying air to pneumatic types of hulk-vehicle discharge system.

Butes Ltd. displayed a twin alternator designed for heavy-duty p.s.v, applications in which either two 60amp machines are combined to give a total output of 120amp or a 60amp machine can be employed with a 30amp alternator to provide an output of 90arnp.

Exhibited by the A-C Delco Division of General Motors Ltd., a thermostat tester incorporates an automatically controlled 2kW heating element and can be used for testing all types of thermostat, the thermometer being calibrated from 54deg C to 100deg C.

A diagram of the company's latest electronic petrol-injection system was displayed by Bosch Ltd All Volkswagen vans and cars powered by the VW 1,500 c.c. engine and destined for the American market, are fitted with the system to meet USA anti-pollution regulations. It is said to improve engine performance and fuel consumption as well as the cleanliness of the exhaust gases. According to a spokesman of the Holset Engineering Co. Ltd., interviewed on the concern's stand, the turbocharger unit of the Turboveyor system can supply air at 15 psi. for air flows up to 500 cuff, 'mm depending on the power unit. Back pressure on the engine is equal to the delivery pressure and the majority of engine makers has approved the use of the turbocharger. It can be fitted to a turbocharger engine in series with the engine turbocharger.

The Dualok automatic safety-beltireel system that was exhibited by Wingard Ltd. is particularly suitable for commercial vehicles because it allows the driver an unrestricted reach, the reel being locked when the vehicle exceeds a certain deceleration by a pendulum mechanism.

An exhauster shown by Feeny and Johnson Ltd. is a particularly compact unit that has a capacity of 5 cu. ft. at 3,000 rp.m.

An air-operated windscreen washer was exhibited by S. Norrish Ltd. that is known as the NorRisk model and can be supplied with a reservoir having a capacity up to I Ogal. Automatic in operation, it can be fitted with an electrical contact that synchronizes the actions of the washer and wiper. The company also displayed a Unimec under-floor safety-vision scanner which covers a field of vision of 360deg in a scanning time of seven seconds.

Known as the model VG. DA, a lightweight semi-trailer support leg was displayed by Davies Magnet Works Ltd. the static capacity of a pair is 44,000lb. with a safety factor of 3 to 1. This was shown alongside an electrically operated leg, available in singleand two-speed form, that can also be hand operated. An Adrolic tailboard lift. exhibited by the company, is known as the Hydrolift and is operated by an electro/ hydraulic system. Depending on the size of the platform, the lift has a capacity of up to 2 tons and weighs up to 8001h.

An Engler hubodometer was exhibited by Ft ubery Owen-Rockwell Ltd. that is of American origin and incorporates a bobweight designed to maintain the recording dial in an upright position. The instrument is completely sealed, is self-fubricating and corrosion-resistant. A range of models is available and each unit is calibrated according to wheel and tyre size, method of mounting and so on.

Although the SAB slack adjuster was publicized well before the Show, it was news that it had been approved for p.s.v. application by 14 corporations and companies and that over 1,300 units have been supplied. The adjuster was shown by the maker. A. B. Svenska of Malmo, Sweden.

by James Millen

THERE were exhibits of interest to appeal to both the technical and non-technical observer in "my' group of stands. The variety of the range was enormous, stretching from a "drizzle" switch at one end of the scale to a Detroit diesel engine at the other.

An exhibit of significance on the Voith Engineering Ltd. stand was the Type 180 hydraulic retarder. This has been developed for use on buses, lorries and trailers as a continuous retarder on long downhill gradients and as a ,retarder brake. Advantages claimed for this equipment are smooth application of braking effect, high, constant braking torque, efficient retardation regardless of the gear engaged, elimination of wheel locking and time delays, substantial reduction in wear and tear of mechanical brakes and increased safety in traffic.

Four models of the Voith hydraulic retarder are available: Type 180 Ml. for installation directly on the transmission; Type 180A1, for installation in front of a trailer axle; and Type 180 A2 for installation behind a trailer axle.

This Voith retarder was fitted to a Leyland Tiger Cub operated by the Western Welsh Omnibus Co. Ltd. last week.

Attracting a great deal of attention was the Burtonwood Mechanical Handling Co. Ltd. stand, where operational displays of three models being shown publicly for the first time were featured. The 5cwt-capacity Foldaway lightweight tail lift for use with small vans is operated electrohydraulically from the vehicle's battery. Platform size is approximately 5ft by 2ft. but this can be extended to make the equipment suitable for use as an ambulance where wheelchairs need to be lifted easily to floor level. Basic price of the ' Foldaway' is £225.

The single-pillar lift shown by Burtonwood has a maximum capacity of 5cwt. It can be fitted quickly to any position on dropside or platform-bodied trucks and also inside the rear of a van.

The Burtonwood folding column 1-ton capacity tail lift has been developed for use with lift-off body vehicles. It can be powered from the battery of a vehicle or by pto from the gearbox. This unit has a cantilever self-closing type platform incorporating an automatic trolley stop ramp. The columns of the equipment fold flat to floor level to permit the loading and unloading of containers.

The Maxi-Lift Mk.6 semi-trailer front support shown by Intertruck is built largely for the Continental market. The 6:1 ratio gives better lifting capacity than previous legs and makes the unit suitable for use with big tanks and for ferry work. It is of square construction and is claimed to be exceptionally durable. Static loading capacity is 60,000lb (27,200k); lifting capacity 49,3001b 127.300k). Single-speed and twin-speed models are available. Approximate prices are: single-speed, £39 5s: twin-speed, £42, The ISO twistlock on the Intertruck stand is to permit trailers to carry loads other than containers. It is fully-retractable and functions by a simple lever operation. This newly designed twistlock has a built-in safety factor in that there is said to be only one breakable part—a metal pin.

Items not previously shown by Tecalemit (Engineering) Ltd. included a solenoid fuel shut-off valve—this valve can also be used as an anti-theft device when fitted to a petrol-. engined vehicle. Also new here was a drizzle switch device for windscreen wipers: this features a 35 sec. delay and override control. The Top-Dog MC 15 heavy-duty clutches shown by Hubert H. P. Trist and Co. Ltd. are claimed to eliminate judder on starting with the heaviest of loads and to give greater flexibility at all engine speeds. Extra strength is gained because the pin-winding process used in

manufacture ensures that the layers of asbestos yarn intersect one another at regular

angles. These clutches have been available on the replacement market for some two months: it is understood that they are to be used as original equipment on some Guy and Leyland vehicles.

Shown here for the first time on the General Motors Ltd. stand was the Detroit diesel engine, Type 8V.71 Vee form engine. This unit, fitted in a Scarnmell Crusader on view on the ground floor, is capable of developing 318 bhp at 2,100 rpm with a maximum torque of 8641b/ft at 1,400 rpm.

by Roger Howell

THE range of exhibits in the section which I covered was particularly wide including displays of basic castings, forgings and fastenings for the manufacturer.

Many of the finished products had been on the market for some time, although several had refinements incorporated. This summary covers electrical products, bus indicator gear, synthetics for spring manufacture, clutch facings, and a pallet-loading device. London Bankside Products Ltd. displayed its boot and bonnet lamp which will retail at approx 17s 6d. Working on either 12 or 24v systems it is fully automatic and switches on when either boot or bonnet is opened, contact being made through the action of a ball bearing in a pivoted glass tube. Also on the London Bankside stand was a combination lamp assembly: flashers, stop-tail and reflectors—with a newly patented bulb-holder, the spring being incorporated in the body of the holder rather than under the contacts.

Butlers Ltd. showed its type 1874 reversing lamp and type 1874 hazard warning lamp. Available in 12volt, 24 and also less-bulb versions for vehicle manufacturers, the lamps are of matching design. Bodies are of moulded polypropylene and Diakon lenses are fitted, specially designed to give an even spread of light. Both lamps have pendant mountings with cable feed and a wide adjustment range.

Transport Engineering and Equipment Ltd. (Kelbus), showed a sophisticated bus indicator gear specially designed for one-man-operated vehicles. With one winder it is possible to operate three individual route numbers and a single destination blind. The actual selector lever is alongside the winder, and the mechanism is designed so that not more than one blind can be operated at once. Noteworthy is the independent springing on each roller spindle to help prevent blind sucking.

Back on accessories. Romac Industries. Ltd. featured combined plug-patch tyre repair units. With the new plug patch scuffiing is eliminated, the special cutting tools being particularly fast in operation. After cementing the plug in position the repaired tyre can be released immediately for use, as the vulcanizing process is completed by heat generated by operation. The patch is for insertion from the inside of the casing.

In the clutch lining field Raybestos-Belaco Ltd. announced that its U.S. 1488 clutch facings are now available for replacement use in this country. The construction of Raybestos facings places all stress bearing metal wires in a circumferential position so that they can more effectively absorb the torsional forces which build up as rotational speed increases. The facings are stated to have a high resistance to bursting which would of course be important in high-speed applications.

Automotive Products Co. Ltd. showed a selection of steering components specifically developed for use on vehicles with either automatic chassis lubrication or which undergo planned lubrication programmes.

Joloda Transport Equipment Ltd. showed the hydraulic application of its original Joloda system. This development has been tested with a South Wales container operator for approximately six months and is now ready for the market. The problem of inserting made-up unit loads into closed containers has been tackled by using portable Joloda tracks which can be laid directly on the floor of the container td any required length or width. Pallet loads are made up and moved along the track by a hydraulic mechanism, the actual braking and locating of the load being under the instant 'control of the operator with a tommy bar.

A dead-man principle applies and should the operator for any reason release the bar the load will immediately be grounded; important with loads of 15-ton deadweight! Pallets of any size, but of standard construction must be landed on lengths of dunnage to permit the removal of the Jolda and tracks, but of course when withdrawn the tracks are ready for immediate use, and one set of equipment can service any number of containers.