A Basic System of Fleet Maintenance

Page 30

Page 31

If you've noticed an error in this article please click here to report it so we can fix it.

By H. R. Morgan

HAVE discovered that the best way to go about a major I overhaul is to sectionalize it, and the vehicle, to fit an attainable time schedule, and to see that it is adhered to.

The time schedule is not, itself, strictly amenable to great flexibility, as its overall value is already determined, first, by the mileage interval between operations, then by the average weekly vehicle mileage, and, again, by the size of the fleet.

Obviously, if the interval be fixed at 75,000 miles, the average weekly mileage be 800, and if the fleet comprises 100 vehicles, the operation will have to be completed upon the whole of the vehicles of the fleet in 93.5 weeks-0.935 weeks per machine.

Literally applied, this would, of course, mean that one vehicle would have to be completed in each working week, if it were proposed to tackle them one at a time"

Having sectionalized the vehicle into engine and controls, gearbox and clutch, rear axle and propeller shaft, front axle and steering, etc., one should next fix the schedule and the times for stripping out and cleaning off, viewing, for reassembling into the chassis, and testing.

It would be a waste of time to attempt to generalize upon what is likely to be found necessary in the way of repairs or replacements, as, quite apart from the fact that it would be akin to "teaching my grandmother," the necessity varies far beyond generalization between tyre and make of vehicle, length of service, and type of wotk that the vehicle has been called upon to perform. I should like, however, to say a word or two upon the operation of "viewing."

Avoiding a Bottleneck

Experience will show that, however careful one has been in the allocation of components when sectionalizing the vehicle, one section can quite easily be ready for viewing some time before the others. The idea is that they should be as near as possible one behind the other in reaching this stage of readiness, so that the whole of the operation will not be held up waiting for the fleet engineer or the foreman to get to them.

Have everything stripped and laid out clean, so that it can be accurately measured and judged. Portable, trestletype benches, temporarily erected for the purpose, in each bay or department, are a decided advantage When viewing. The record clerk should accompany the viewing executive, record the result of the operation, and make out an order upon the stores, in compositeform if desired, one for each section, so that there shall be no delay in commencing the reconditioning.

Viewing is an important operation and cannot be hurried, but it is surprising how quick one can become.

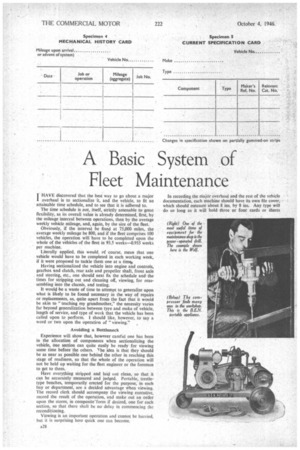

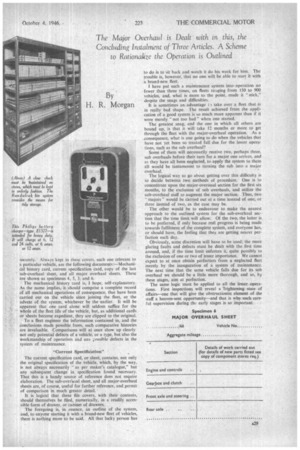

In recording the Major overhaul and the rest of the vehicle documentation, each machine should have its own file cover, which should measure about 8 ins, by 8 ins. Any type wilt do so long as it will hold three or four cards or sheets securely. Always kept in these covers, each one relevant to a particular vehicle, are the following documents:—Mechanical history card, current specification card, copy of the last sub-overhaul sheet, and all major overhaul sheets. These are shown as specimens 4, 5, 3, and 6.

' The mechanical history card is, I hope, self-explanatory. As the name implies; it should comprise a complete record of all mechanical operations of consequence, that have been carried out on the vehicle since joining the fleet, or the advent of the system, whichever be the earlier. It will be apparent that one card alone will seldom suffice for the whole of the fleet life of the vehicle, but, as additional cards or sheets become expedient, they are clipped to the original.

To a fleet engineer the information contained in, and the conclusions made possible from, such comparative histories are invaluable. Comparisons will at once show up clearly not only potential defects of a vehicle, or a type, but also the workmanship of operatives in.] any ,:ossible defects in the system of maintenance.

"Current Specification" • The current specification card, or sheet, contains, not only the original specification of the vehicle, which, by the way, is not always necessarily "as per maker's catalogue," but any subsequent change in specification found necessary. That this is a handy source of reference does not require elaboration. The sub-over:Liul sheet, and all major-overhaul sheets are, of course, useful for further reference, and permit of comparison in much greater detail.

It is logical that these file covers, with their contents, should themselves be filed, numerically, in a readily accessible form of drawer, or cabinet of drawers.

The foregoing is, in essence, an outline of the system, and, to anyone starting it with a brand-new fleet of vehicles, there is nothing more to be said. All that lucky person has to do is to sit back and watch it do his work for him. The trouble is, however, that no one will be able to start it with .a brand-new fleet.

I have put such a maintenance system into operation no fewer than three times, on fleets ranging from 150 to 900 vehicles, and, what is more to the point, made it "stick," despite the snags and difficulties. It is sometimes an.advantage Ii take over a fleet that .is in really bad shape. The result achieved from the application of a good system is so much more apparent than if it were merely "not too bad" when one started.

The greatest snag, and the one in which all others are bound up, is that it will take 12 months or more to get through the fleet with the major-overhaul operation. As a consequence, what is one going to do when the vehicles that have not yet been so treated fall due for the lesser operations, such as the sub overhaul?

Some of them will necessarily receive two, perhaps three. sub overhauls before their turn for a major one arrives, and as they have all been neglected, to apply the system to them all would be tantamount to turning the sub into a major overhaul.

The logical way to go about getting over this difficulty is to decide between two methods of procedure. One is to concentrate upon the major-overnaul section for the first six months, to the exclusion of sub overhauls, and utilize the sub-overhaul staff to augment the major section. Thus, two " majors" would be carried out at a time instead of one, or three instead of two, as the case may be.

The other would be to endeavour to make the nearest approach to the outlined system for the sub-overhaul section that the time limit will allow. Of the two, the latter is to be preferred, if only because real progress is being made towards fulfilment of the complete system, and everyone has, or should have, the feeling that they are getting nearer perfection each day.

Obviously, some discretion will have to be used; the more glaring faults and defects must be dealt with the first time around, and, if the time limit 'enforces it, quite possibly to the exclusion of one or two of lesser importance. We cannot expect to at once obtain perfection from a neglected fleet merely by the inauguration of a system of maintenance. The next time that the same vehicle falls due for its sub overhaul we should be a little more thorough, and so, by these stages, aim at perfection.

The same logic 'must be applied to all the lesser operations. First inspections will reveal a 'frightening state of affairs—one that will give the obstructionist element of the staff a heaven-sent opportunity—and that is why such careful supervision during thc early stages is so important