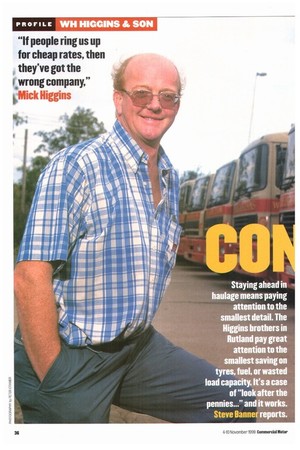

WH HIGGINS & SON

Page 38

Page 39

Page 40

If you've noticed an error in this article please click here to report it so we can fix it.

Staying ahead in haulage means paying attention to the smallest detail. The Higgins brothers in Rutland pay great attention to the smallest saving on tyres, fuel, or wasted load capacity. It's a case of "look after the pennies..." and it works. Steve Banner reports. INith dis,eser prices at such exorbitant levels, the last fraction of a kilometre has to be wrung out of every litre you buy. If your work is payload-sensitive you have to cram the last legal kilo; and the price of tyres means you have to get the last kilometre out of them too, without compromising on safety. Those lessons have been well learned over the past four decades by bulk cement, fly ash and sand haulier WH Higgins & Sons, based in South Luffenham, Rutland. Brothers Barry and Mick Higgins run it now; their father started the firm in 1962. He kept "The Railway Inn" in the nearby village of Ketton but ran a truck for his small animal feed business. Then Ketton Cement, now Castle Cement, offered him some haulage work. By 1967 he had three trucks on the road and by the early seventies the Higgins family was running bulk cement tankers.

Today WH Higgins operates eight tractors: three ERF ECIos, two ERF ECris, a pair of Leyland Daf 85 Series, and a Leyland Daf 85CF Series. "We're running four of the combinations on six axles," says Mick. "We bought the most recent unit as a 6x2 and had three of the others converted."

The six-axle rigs gross at 41 tonnes, and the brothers aim to convert the rest of the fleet (currently running on Eve axles at tonnes) to match them. "We're getting a 28.7-tonne payload a tonnes," says Mick. "That's the best part of three-quarters tonne more than most of our competitors are managing." There's novagic trick to this impressive figure: just relentless attention to detail, starting with alloy wheels: "We've been on alloys since 1984, and we favour Alcoa,says Barry. And the 6x2s have the bulk blower mounted on the back of the tractor unit rather than on the trailer, so it can be driven off the unit's engine. Barry points out that the Drum D500 blower they're now fitting weighs only r6okg, compared with 750kg for a blower installed on the trailer, and driven by a donkey engine.

The only drawbacks are that if you drive the blower off the unit you're running on white diesel rather than red, and the operation will only be as quiet as the tractor unit's engine," says Barry. The latest donkey engines are very quiet, but they are expensive and can sometimes be unreliable.

When the Higgins brothers take delivery of an ERF they immediately shave off 12okg by fitting their own light battery carrier and swapping some of the chassis' steel brackets for alloy. Alloy wing stays are installed too, along with a vertical exhaust, which is lighter than a conventionally positioned system.

The firm's eight 36m3 tank trailers are almost always busy. Metalair manufactured the older tanks: the newer units come from Feldbinder (which bought Metalair) but the most recent tank in the fleet comes from Thompson Heil.

Only two are tippers, and they are used to transport sand. Nontippers are safer, lighter, and discharge their loads more rapidly, the brothers believe. "With the Thompson Heil tanker, which was at TankCon, we're regularly blowing 28 tonnes off in 20 minutes," says Mick. Our best yet is 28 tonnes in 14 minutes,"

"It's got a low centre of gravity, which means good roadholding, and it's light," adds Barry. "All the trailers are on air, and they've got rear steer axles." He's a convinced advocate of rear-steers because in his experience they can more than quadruple trailer tyre life.

Fuel consumption

"Average .tyre life on a triaxle is 8o,000km, but by using rear-steers we're now achieving a minimum 250,000km," he says. "We've just taken one tyre off that had done 375,000km, which is the best we've achieved." Rear-steers help manoeuvrability, Barry continues, and help improve fuel consumption. Admittedly at around o.impg this increase isn't dramatic, but every bit helps.

Steer axles also reduce the stress placed on a trailer when the driver is manoeuvring or cornering, he says. "That means it should last longer. A rear-steer adds zookg to the weight of your trailer, but this is outweighed by the other savings."

The first rear-steer systems the Higgins brothers had fitted were sourced from York. Since then they've specified SAE, and more recently BPW, which is installed on the Thompson Heil tanker. The first BPW self-steers went into service five years ago, and they've had good experiences with BPW axles, especially when it comes to maintenance.

"When you undo the hub nut on B PW's ECO hub, it pulls off in one to expose the brake," says Barry. "One man can remove a wheel, reline the brake, and have the job completed in under half an hour." Mick adds: "We're doing at least 270,000km between relines."

"We've never had a bearing failure with BPWs, and we used to get through a lot of bearings at one time," Barry reports. The firm services all its own trucks and tankers, and takes on a lot of third-party maintenance work as well.

At least 3o trucks, vans and cars pass through the workshop every week, and the four fitters also MoT test cars and vans. "We're agents for Romatic speed limiters and we're developing air conditioning service and repair as one of our specialities," says Barry. This level of activity has led them to buy some of the more advanced equipment for maintaining modern vehicles.

All the trucks are equipped with ICS Black Box on-board monitors as a quick and efficient means of checking compliance with the drivers' hours rules. "If the Black Box reveals anything amiss, then we examine the tacho chart," he says.

Usually acquired new, most of the firm's tractors are limited to 54mph. "Lower speed limits mean lower maintenance bills," Barry remarks. The five most recent acquisitions are also equipped with cruise control. "If you're going down the motorway, you can set it, and maintain the speed you require," he says. "You haven't got your foot going up and down all the time, and it's better for fuel consumption too."

The brothers reckon that 360 to 38ohp is perfectly adequate on the runs they do, even at 41 tonnes: "We don't go up into the mountains a lot," says Mick. "If you buy 400hp tractors the drivers will only want 45ohp next year! We've even got a 325hp ERF operating at 41 tonnes, and the driver reckons it doesn't perform much differently from when it was at 38 tonnes."

The Euro-I ERF is returning just under 8mpg, compared with the 9mpg-plus being returned by the fleet's more modern Euro-2 vehicles. "The ERF ECtis are no better or no worse than the Leyland Dais fitted with mechanical fuel injection," says Barry. "The only drawback with the Leyland Dafs is that they're at least half a tonne heavier than our ERFs," Mick adds.

The Higgins trucks go down into the West Country, as far north as Middlesbrough, and make regular forays into London. "We go to block plants, tarmac plants, and other building industry-related operations," says Mick.

Each vehicle covers II o, 000 to 120,000km a year, and tractors have traditionally stayed with the fleet for four to five years.

"However, we'll keep the 6xzs longer because of the extra expense involved in fitting a third axle," says Barry. "We'll maybe change the clutch once, if that, during the life of the vehicle," says Mick. "Otherwise it's brakes and filters; general wearing parts."

Soaring price

Specialising in an area which requires a lot of investment in high-tech tackle has to a degree insulated WH Higgins from the cutthroat world of general haulage—but not from the soaring price of diesel. "It's the cost of fuel that's the real killer," Mick confirms. "I reckon it's gone up steadily over the past four months, and the increase has cost us boo each month."

They have no option but to pass it on to their customers. "And if they don't accept it, then I'm afraid we can no 'longer work for them," he adds.

The firm is simply not prepared to cut its throat by taking on unprofitable work, he concludes: "If people ring us up for cheap rates then they've got the wrong company. We'll do the job properly, and we've got the right kit, but customers have got to pay for it. Anyone can be a busy fool."

FACTFILE W H Higgins & Son

BASED South Luffenham, Rutland.

FOUNDED Ketton, 1962.

—

CONTACT Mick Hi fls.

FLEET Eight tractive units: five ERFs, three

Leyland Dafs with eight bulk powder tanker trailers. Four of the rigs run at 41 tonnes. Buys new. Most recent acquisition: A Leyland Daf 135CF tractive unit that joined the fleet last September.

SPECIALITY Transporting cement, fly-ash, and sand.