Semi trailer Hopper Body for Rapid Discharge

Page 40

If you've noticed an error in this article please click here to report it so we can fix it.

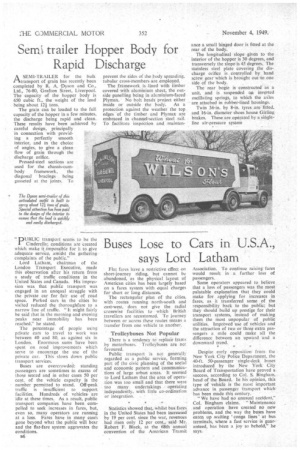

ASEM1-TRAILER for the bulk transport of grain has recently been completed by R. A. -Dyson and Co., Ltd., 76-80, Grafton Street, Liverpool. The capacity of the hopper body is 650 cubic ft., the weight of the load being about 12i tons.

The grain can be loaded to the full capacity of the hopper in a few minutes, the discharge being rapid and clean. These results have been achieved by careful design, principally in connection with providing a perfectly smooth interior, and in the choice of angles, to give a clean flow of grain through the discharge orifice.

• Pressed-steel sections are used for the chassis-cumbody framework, the diagonal bracings being gusseted at the joints. To prevent the sides of the body spreading, tubular cross-members are employed.

The framework is lined with timber covered with aluminium sheet, the outside panelling being in aluminium-faced Plyrnax. No bolt heads project either inside or outside the body. As a protection against the weather the top edges of the timber and Plymax are embraced in channel-section steel rail. To facilitate inspection and •mainten

ance a small binged door is fitted at the rear of the body.

The longitudinal slope given to the interior of the hopper is 30 degrees, and transversely the slope is 45 degrees. The stainless steel plate covering the discharge orifice is controlled by hand screw gear which is brought out to one side of the body.

The rear bogie is constructed as a unit, and is suspended an inverted oscillating springs, to which the axles are attached in rubber-lined housings.

Twin 36-in. by 8-in. tyres are fitted, and 16-in, diameter shoes house Girling brakes. These are operated by a singleline air-pressure system