Small Improvement Caintain the Breed

Page 62

Page 63

Page 64

Page 65

If you've noticed an error in this article please click here to report it so we can fix it.

Latest Morris 1-ton Van is a Direct Descendant of the 1939 P.V. Model : Changes are Mainly in Body Design, but New B.M.C. Petrol Engine is now Used • By John F. Moon, A.M.I.R.T.E.

SINCE the introduction, shortly before the 1939-45 war, of their 15-cwt. delivery van, MorrisCommercial Cars, Ltd., have had a reputation for setting the pace in the design of delivery vans of this capacity. The latest descendant from the original design is the LD.1M 1-ton van and its performance on test showed that the Morris engineers have no intention of relinquishing their lead in this field.

When the original van was introduced in 1939 it was noteworthy for its forward driving position, giving maximum payload capacity without excessive size, and sliding doors to the driving compartment. It had an overhead-valve petrol engine, fourspeed constant-mesh gearbox and Lockheed hydraulic braking, which are retained in the current design.

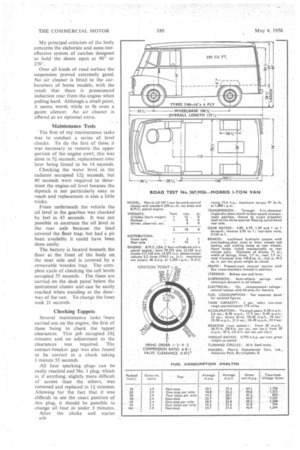

The power unit used in the latest van is a B.M.C. four-cylindered overhead-valve petrol engine with a capacity of 2.2 litres. and a maximum output of 46 b.h.p. at 3,250 r.p.m.— 4 b.h.p. more than that of the NPFC unit fitted to the old P.V. model. Maximum torque has also been increased by 6 lb.-ft.

The new engine gives an extremely lively performance without causing the fuel-consumption rate to be excessive, but for those operators who are more interested in economy and can afford the slightly higher initial outlay, the van is available With a 2.2-litre 55 b.h.p. oil engine (The Commercial Motor, February 18, 1955). The gearbox is still built to the original design and so are the front and rear axles.

Body styling has been drastically changed, however, and the present body has attractive sweeping lines which provide a high degree of all iru round visibility for the driver, good access from front and rear to the payload space, and a rigid form of construction which will withstand a good deal of misuse without damage.

Flush-fitting sliding doors are now used to provide a smooth exterior line which facilitates decoration. The body consists of metal panels on a timber frame and has a capacity of 235 cu. ft., excluding the space alongside the driver when no passenger seat is fitted.

As supplied for test, the van Stood at a kerb weight of 1 ton 12 cwt. A ton of iron weights was added and a further 6 cwt. was made up of driver, two observers, test equipment and cans of fuel, making the gross weight 2 tons 18 cwt., as compared with the maximum permissible gross weight of 2 tons 12 cwt.

• At the time of the test the country was in the grip of winter and the ambient temperature varied between 30° F. and 36° F. It would have been pointless, therefore, to subject the van to a long hill-climb (ofwhich there is none near Birmingham) to assess the engine-cooling properties. I contented myself with a hurried stop-start test on the 1-in-7 gradient in Gough ,Street, in central Birmingham.

The surface on this gradient was becoming slippery because of snow, but an easy first-gear start was made at low engine revolutions without slipping the clutch. I then attempted a rather optimistic second-gear start, but although the engine did manage to move the vehicle a few feet, revolutions dropped as soon as the clutch

was fully engaged and the engine rstalled.

Judging by the first-gear performance, 1-in-4 gradients should be well within the capabilities of the van. When facing both up and down the hill the hand brake held the vehicle easily with several ratchet notches in hand.

The Chester road at Castle_ Bromwich was used for braking and acceleration tests. By this time the falling snow had made the road surface very wet, but as there was no sign of the weather changing I had to conduct the braking tests under these adverse conditions. When braking from 20 m.p.h. and 30 m.p.h., it was hardly surprising that all the wheels locked on each occasion, but even under these conditions the vehicle was controllable and came to rest in a straight line.

From 20 m.p.h. the average retardation rate given by the stopping distances is 0.65g. and from 30 m.p.h. is 0.67g. A comparison of these figures with the maximum deceleration readings provided by the Tapley meter (67.5 per cent. and 66.5 per cent, respectively) shows that retardation is commendably smooth and devoid of surge or grab.

Emergency stops from 20 m.p.h., using the hand brake alone, produced an average Tapley-meter reading of 34 per cent, this figure being accompanied, as might be expected in the circumstances, by instant locking of the rear wheels.

Acceleration times were taken up to 40 m.p.h. and top gear was engaged at about 36 m.p.h. on each occasion, although 40 m.p.h. can be reached in third gear. When pulling away from 10 m.p.n. in direct drive the engine and transmission were commendably smooth and there was no sign of pinking on this, or on any other, occasion during the test.

While on this relatively level and wide stretch of road a high-speed run was made to assess maximum speed, which was discovered to be approximately 55 m.p.h. The vehicle at this speed was perfectly steady and safe to handle, and braking brought it down to more legal speeds without any danger, even on a slippery road.

My favourite five-mile stretch of road between Sheldon and Meriden was the scene of the fuel-consumption tests. It is undulating and carries a lot of heavy trunk traffic. It usually provides good average results for consumption tests and the course was covered in each direction to reduce the margin of error.

Seven runs were made in all and the results obtained are shown in the detailed data panel. During the " stops-per-mile " tests the van was halted for 15 sec. each time with the engine idling. The position of each stop was not carefully picked and some halts were made on downgrades and some on up-grades.

During this series of tests the lower third of the radiator stack was blanked off and the running temperatures varied between 158° F. and 168° F., the higher temperature being close to the figure at which the thermostat is set to open. A 2-gal. test tank was used to obtain these results, this . being topped up to a predetermined level at the end of each test. •

As the vehicle had covered only 120 miles before I took it over, it was still mechanically stiff, and good as the figures are, slight improvements should be noticeable after the first few thousand miles.

drove the vehicle several times during the two days' testing and found it extremely pleasant to handle. The steering is light and positive and no road shocks are transmitted to the wheel. The lock is extremely good and enables the van to be manceuvred into some exceptionally tight corners without trouble. The other controls are all light and well placed.

Deep windows are incorporated in the cab doors and have sliding panels which are well arranged for giving hand signals. The sliding doors, which work smoothly, can be held, open when running. When fully open they provide easy access to the driving seat and enable goods in the front of the payload space to be reached from alongside the vehicle.

Body details include a full-width shelf for oddments below the windscreen and a small cubby hole in the driver's seat pedestal which could be used for notebooks or other personal effects. A tool compartment below the front floorboards is reached through a trap.

My principal criticism of the body concerns the elaborate and none-tooeffective system of catches designed to hold the doors open at 900 or 270'.

Over all kinds of road surface the suspension proved extremely good. No air cleaner is fitted to the carburetters of home models, with the result that there is pronounced induction roar from the engine when pulling hard. Although a small point, it seems worth while to fit even a gauze silencer. An air cleaner is offered as an optional extra.

Maintenance Tests

The first of my maintenance tasks was to conduct a series of level checks. To do the first of these it was necessary to remove the upper portion of the engine cowl; this was done in Si seconds, replacement time later being found to be 14 seconds.

Checking the water level in the radiator occupied 12i seconds, but 40 seconds were required to determine the engine-oil level because the dipstick is not particularly easy to reach and replacement is also a little tricky.

From underneath the vehicle the oil level in the gearbox was checked by feel in 43 seconds. It was not possible to ascertain the oil level in the rear axle because the load covered the floor trap, but had a pit been available it could have been done easily.

The battery is located beneath the floor at the front of the body on. the near side and is covered by a removable wooden trap. The complete cycle of checking the cell levels occupied 55 seconds. The fUses are carried on the dash panel below the instrument cluster and can be easily reached when standing at the doorway of the van. To change the fuses took 21 seconds.

Checking Tappets

Several maintenance tasks "were carried out on the engine, the first of these being to check the tappet clearances. This job occupied 10i minutes and no adjustment to the clearances was required. The contact-breaker gap was also found to be correct in a check taking 1 minute 55 seconds.

All four sparking plugs can be easily reached and No. 1 plug, which is, if anything, slightly more difficult of access than the others, was removed and replaced in I i minutes; Allowing for the fact that it was difficult to see the exact position of this plug, it should be possible to change all four in under 5 minutes.

After the choke and starter

controls had been disconnected, the lower section of the engine cowl was removed in 1 minute 50 seconds, replacement time being 3 minutes 10 seconds. With this section of the cowl out of the way, the gauze filter in the petrol-pump housing was removed, cleaned and replaced in a minute. The only-other .filter in the fuel system is in the carburetter banjo union and this was attended to in 50 seconds. The braking system is straightforward to maintain in itself and bleeding is a 6i-minute job, whilst the fluid reservoir level can be inspected in 11 minutes. Adjustment of the brakes is complicated, however, by the necessity of removing each wheel to reach the internal snail-cam adjusters.

As a final task, I decided to change a headlight bulb. This was done in 1 minute 40 seconds. It was surpris

ingly easy, considering how difficult it is to remove and replace the rims of some lamps. The van lamps have concave rims, which -were extremely easy to manage.

By and large, there should be no difficulty in carrying out normal road maintenanceon this vehicle, and assuming that this is ,done correctly and • at the proper intervals, as laid down, the LD.1M should give good service for many years.