FUEL FOR THOUGHT

Page 66

Page 67

If you've noticed an error in this article please click here to report it so we can fix it.

Getting more miles from your fuel depends on management setting the pace. Emma Penny finds out how companies can cut their bills.

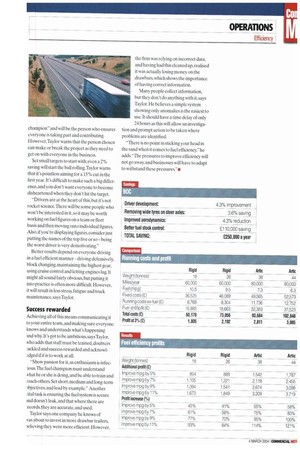

With diesel prices creeping back above 80p/lit. getting more miles for your money is becoming an increasingly attractive idea. If you've a fuel bill of £50,000 a year. cutting it by 50/0 — which is reckoned to be a fairly easy target to hit — could save you £2.500 a year. And while that amount spread over a year might not seem like much,it all adds up in a world where margins are increasingly tight.

Research has found that only 21% of companies know the amount of fuel used in their fleet. but of those that do, some have tackled the fuel-saving challenge head-on. One member of staff at BOC was appointed as the company's -fuel champion" and was given the task of saving £250.000 a year —and achieved it (see box).

Making such savings, though, depends on a whole chain of events, starting at the top of the company as any plans to save fuel must be driven from the top, says fuel advisor Kevin Taylor.

He points out that measuring what's going on is crucial to any fuel-saving plans. It's vital to know how much is being spent on diesel before any efficiency drive starts so that savings can be measured. "if you can't measure it, you can't manage it and you can discount any savings if you don't do it," he warns.

Plenty of savings

There are plenty ut savings to be made, says Taylor. but achieving them is not an easy task.

Maintaining any improvements takes time and effort, and that requires everyone's enthusiasm, from company directors to drivers Many people believe there are big bar riers to better fuel figures:research shows that more than a third think the savings are not going to be worthwhile, while a further 42% say they're too expen sive."These are perceived barriers," says Taylor."The savings are there, and better fuel efficiency doesn't have to rely on gadgets. Small improvements in fuel use generate much larger improvements in profitability."

The first move should be to find someone within the company who will take on responsibility for the project they'l be the "fuel champion" and will be the person who ensures everyone is taking part and contributing. However.Taylor warns that the person chosen can make or break the project as they need to get on with everyone in the business.

Set small targets to start with; even a 2% saving will start the hall rolling.Taylor warns that it's pointless aiming for a 15% cut in the first year. It's difficult to make such a big differ,. ence, and you don't want everyone to become disheartened when they don't hit the target.

"Drivers are at the heart of this. but it's not rocket science.There will be some people who won't be interested in it.so it may be worth working on fuel figures on a team or fleet basis and then moving onto individual figures. Also, if you're displaying figures. consider just putting the names of the top five or sobeing the worst driver is very demotivating."

Better results depend on everyone driving in a fuel efficient manner driving defensively, block changing, maintaining the highest gear, using cruise control and letting engines lug. It might all sound fairly obvious, but putting it into practice is often more difficult. However, it will result in less stress, fatigue and truck maintenance, says Taylor.

Success rewarded

Achieving all of this means communicating it to your entire team, and making sure everyone knows and understands what's happening and why. Ifs got lobe ambitious, says Taylor, who adds that staff must be trained.doubters tackled and success rewarded and acknowledged if it is to work at all.

"Show passion for it, as enthusiasm is infeclous.The fuel champion must understand what he or she is doing, and be able to train and :oach others. Set short,medium and long-term kjectives, and lead by example." Another rital task is ensuring the fuel system is secure ind doesn't leak, and that where there are .ecords, they are accurate, and used.

Taylor says one company he knows of was about to invest in more drawbar trailers. )elieving they were more efficient. However, the firm was relying on incorrect data, and having had this cleaned up, realised it was actually losing money on the drawbars, which shows the importance of having correct information.

Many people collect information, but they don't do anything with it, says Taylor. He believes a simple system showing only anomalies is the easiest to use. It should have a time delay of only 24 hours as this will allow an investigation and prompt action to be taken where problems are identified.

"There is no point in sticking your head in the sand when it comes to fuel efficiency," he adds."The pressures to improve efficiency will not go away. and businesses will have to adapt to withstand these pressures."•