FIAT FLATTENS OUT THE HILLS

Page 81

Page 82

Page 83

Page 84

If you've noticed an error in this article please click here to report it so we can fix it.

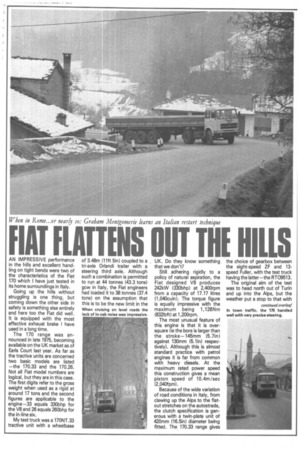

AN IMPRESSIVE performance in the hills and excellent handling on tight bends were two of the characteristics of the Fiat 170 which I have just tested in its home surroundings in Italy.

Going up the hills without struggling is one thing, but coming down the other side in safety is something else entirely and here too the Fiat did well. It is equipped with the most effective exhaust brake I have used in a long time.

The 170 range was announced in late 1975, becoming available on the UK market as of Earls Court last year. As far as the tractive units are concerned two basic models are listed —the 170.33 and the 170.26. Not all Fiat model numbers are logical, but they are in this case. The first digits refer to the gross weight when used as a rigid at around 17 tons and the second figures are applicable to the engine-33 equals 330bhp for the V8 and 26 equals 260bhp for the in-line six.

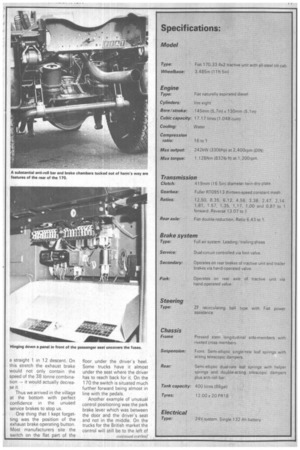

My test truck was a 17ONT.33 tractive unit with a wheelbase

of 3.48m (lift 5in) coupled to a tri-axle Orlandi trailer with a steering third axle. Although such a combination is permitted to run at 44 tonnes (43.3 tons) gcw in Italy, the Fiat engineers had loaded it to 38 tonnes (37.4 tons) on the assumption that this is to be the new limit in the When cruising on level roads the lack of in-cab noise was impressive.

UK. Do they know something that we don't?

Still adhering rigidly to a policy of natural aspiration, the Fiat designed V8 produces 242kW (330bhp) at 2,400rpm from a capacity of 17.17 litres (1,040cuin). The torque figure is equally impressive with the maximum being 1,128Nm (832Ibft) at 1,200rpm.

The most unusual feature of this engine is that it is oversquare (ie the bore is larger than the stroke-145mm (5.7in) against 130mm (5.1in) respectively). Although this is almost standard practice with petrol engines it is far from common with heavy diesels. At the maximum rated power speed this construction gives a mean piston speed of 10.4m/sec (2,040fpm).

Because of the wide variation of road conditions in Italy, from clawing up the Alps to the flatout stretches on the autostrada, the clutch specification is generous with a twin-plate unit of 420mm (16.5in) diameter being fitted. The 170.33 range gives the choice of gearbox between the eight-speed ZF and 13speed Fuller, with the test truck having the latter—the RT09513.

The original aim of the test was to head north out of Turin and up into the Alps, but the weather put a stop to that with heavy snow for the whole of the previous week. Accordingly we used one of the Fiat development test routes, to the south of Turin by autostrada to Asti and then into the hills around Alba.

This section was chosen by Fiat to test the durability and reliability of the transmission especially in the lower gears. Having driven over it I wonder if it was chosen to test the durability of the drivers as well.

On the first autostrada section of the test, the thing that impressed me most was the lack of in-cab noise. Admittedly cruising at the legal maximum of around 50mph was not exactly stretching the 170 to its limits, but considering that dire predictions of high noise levels coming from oversquare V8's have been made in the past, I can report that this is not a problem with the Fiat.

When we turned off the motorway type of road and into the mountains, this was where the torque spread of the big engine really came into its own.

For an engine of this size the maximum torque figure is not particularly remarkable—the uprated Scania DS14 engine for example produces 1,480Nm (1,090Ibft) from a turbocharged V8 of 14 litres (845cuin) but the engine speed range over which this torque can be used is far more impressive. According to the power curve for the engine, the maximum torque of 1,128Nm (832Ibft) is produced between 1,100 and 1,400rpm but at below 1,000rpm it is still giving well in excess of 750Ibft.

At the other end of the scale the torque does not fall below this last figure until around 1,800rpm, so it can be appreciated how wide the torque speed range is in practice.

This came in extremely handy in the hills because the route was a very twisty one indeed with almost every bend being a complete 180° hairpin and the average gradient being around 1 in 11/12.

The bends themselves were not so much of a problem compared to the distance between them. With the 15-plus metre overall length of the outfit I was lining up the tractive unit for the next bend while the trailer bogie was still struggling around the last corner. Because of the constant steering necessary—from full lock to full lock and back again —every few seconds, there wasn't a great deal of free time in which to change gear.

However, owing to the torque characteristics of the engine it was possible tO leave the truck in fourth (or fifth if you count the crawler as first gear) and drive it as an "automatic". On the "straight" portions between the bends the engine would reach just over 2,000rpm falling to around 1,000rpm coming out of the corners.

At this last speed it was simply a question of keeping my foot hard down when the 170 just pulled away as smoothly as a turbine. If at this stage you are thinking that I was impressed with the engine you would be quite right —1 was.

One aspect of driving the 170 in the hills intrigued me and this was the technique for performing a hill restart. To give a bus (which didn't bend in the middle) a bit more room on one of the bends, I pulled over to the side and stopped. The restart fooled me completely. The correct procedure on such a gradient—it was a 1 in 10—is to feed in the clutch at around 600rpm (yes, SIX hundred rpm) until it is fully home and then floor the throttle and let the torque do the rest. Any attempt to use more revs results in a load of wheelspin or the cab bucking around, and a 1 in 10 in the snow is no place for either.

With a heavy truck, going down a hill can pose as many problems as going up, but in different areas. In such a country an exhaust brake which actually works is essential, and the 170 had one of the best I have tried in a long time. Coming down out of the mountains into Alba the bends decrease in number with the final run being a straight 1 in 12 descent. On this stretch the exhaust brake would not only contain the speed of the 38 tonne combination -it would actually decrease it.

Thus we arrived in the village at the bottom with perfect confidence in the unused service brakes to stop us.

One thing that I kept forgetting was the position of the exhaust brake operating button. Most manufacturers site the switch on the fiat part of the floor under the driver's heel. Some trucks have it almost under the seat where the driver has to reach back for it. On the 170 the switch is situated much further forward being almost in line with the pedals.

Another example of unusual control positioning was the park brake lever which was between the door and the driver's seat and not in the middle. On the trucks for the British market the control will still be to the left of the driver, but this will make it the middle of the cab for the right-hand-drive versions. The park brake lever also had a very strong indent spring so a hefty heave was necessary to make sure it was locked properly.

On the rare occasions when I needed to change gear in the mountains the Fuller box was its normal quick changing self, but care was needed to ensure a clean change due to the very slow die down of the engine.

The total distance covered on the test. including the short urban amble back to the factory, was 218km (135 miles) and for this we used exactly 150 litres (33ga1) of diesel. This gave an overall fuel consumption of 68.8 lit/100km (4.1 mpg) and while this sounds catastrophic don't forget the type of roads I took the truck over. You don't get Gardner-like fuel consumption figures in the mountains.

To give an idea of the type of road, the final mountain section of 26km (16 miles) took 70 minutes for an average speed of 23.3km/h (13.8mph) -most of this in fourth gear.

From the driver's seat the instrumentation was comprehensive and the major and minor controls were within easy reach. The left-hand dial which comprises warning gauges for five separate functions (fuel, oil, water and the various air circuits) was difficult to scan quickly requiring a careful look to sort out which was which. Although this would improve with more familiarity of the truck I would personally prefer separate dials.

In the past Fiat trucks have often been accused of being too heavy. Admittedly they have never been among the F86 and Buffalo in terms of kerb weight, but on the other hand Fiat has always quoted the kerb weight with a full tank of fuel which, in the case of the 170.33, is 400 litres (88gal). The dry kerb weight of the test truck was 6.48 tonnes (6 tons 8cwt) while Fiat give the kerb weight in running order -including the driver -at exactly 7 tonnes (6 tons 18cwt).

Another of the criticisms levelled at the earlier top-weight Fiats has concerned the lack of a tilt cab. The latest model has changed all that with a hydraulically tilted cab which goes over to a maximum angle of 60 giving all the space that a mechanic could want. This was definitely a long overdue improvement to Fiat trucks.

However much I was impressed with the V8 170, I still feel it will be the sixcylinder 170.26 which will take the lion's share of Fiat sales in this weight category in the UK. The 170.33 in very much in the running for Continental hauls, but at 32 tons the power and torque available become merely academic.