Rough Work for Road Transport

Page 20

Page 21

If you've noticed an error in this article please click here to report it so we can fix it.

By C. S. DUNBAR, M.1nst.T.

POKI-LAND stone has been quarried for at least 800 years, and possibly'as far back as the time of the Romans. It will be many years before the supply is exhausted. The quarries are worked mainly by the Bath and Portland Stone Firms, Ltd., and the South-Western Stone Co., Ltd., the former having the bulk of the output.

The stone is reasonably easy to quarry, because of the geological formation. From north to south of the island the rock is divided by gullies about 90 ft. to 120 ft. apart; across the sections so created are diagonal joints running from north-west to south-east (called locally "southers ") and across these again, from east to west, are . other fissures called " casters " and ‘. westers "; _in elevation there are also to be seen horizontal risers.

Nature has therefore created almost ready-made cuboid or rhomboid forms, and quarrying consists of selecting the right sized piece of stone for the job in view and forcing it off by wedges. There is no blasting. Before the war Bath and Portland Stone Firms were producing about two million cubic feet per annum, but the present restrictions on building have cut output by more than hail Topography .Ilinders Transport The great difficulty is and always has been that of transport owing to the peculiar configuration of the. island. The only natural connection with the mainland is the long and narrow Chesil Beach on the north-west. From the beach, and from the sea all round, the island rises precipitously and the steep gradients and hairpin bends have to be seen to be appreciated. Until the 1930s stone was hauled from the quarries on trailers drawn by traction engines and it was an interesting sight to see the skill with which the drivers manoeuvred their awkward vehicles and trains in the difficult conditions.

The traction engines went as far as the hairpin bend overlooking Fortune's Well, where one can still see a disused crane and the remains of a tramway. Here the blocks were transferred to flat cars which were pulled by horses to a rope railway. This worked over a 1-in-2

cl4 gradient down to a pier whence the stole was loaded for dispatch to destinations all over the world.

The use of traction engines of the old type became impossible after 1930, because of the legalprohibition of iron-shod wheels. Bath and Portland Stone Firms then tried Sentinel steam wagons with solid rubber tyres, but these were also killed by penal taxation. It seemed doubtful at that time whether pneumatic tyres would stand up to the exceptionally rough conditions in the quarries, or if any internal-combustion vehicle would prove continuously adequate to the work, since loads of up to 16 tons in a single piece had often to be hauled up an incline of as much as 1 in 31.

A Mixed Fleet Experiments were made with several makes of vehicle and after trials over a period of 18 months it was decided to standardize on A.E.C.s. During the warit was necessary to depart slightly from this rule, and'to-day the fleet consists of six Mammoth Majors, 12 Monarchs (including two petrol-driven with Marshall gearboxes), two 5-ton Cornmers, one mechanical horse, a Fordson tipper and are Albion tipper. The A.E.C.s are given a back axle ratio of 61; 1. To withstand the weight which is dumped on the floors, all vehicles are fitted with a substantial timber bed.

The tyre problem was solved by standardizing on Goodyears although; here again, war conditions frequently necessitated a departure from this rule. • Heavy duty 36 by 8 covers have been quite satisfactory and in pre-war days these averaged 60,000 miles per set. One set actually covered 103,000 miles and one individual tyre 105,000. Nowadays 20,000 is a good figure. On the tippers, in order to help in getting out of the muddy and loose excavations, 900 by 20 tractor-lug tyres were successfully tried on the rear wheels. The alterations necessary to fit these have been well justified.

The scrapping of the traction engines led to the disuse of the aid tramway and stone is now taken to railhead or to the loading piers by road. Quite often it is taken by road transport direct to the site, so that quite big mileages are put up.

Considerable care is taken over maintenance and

aair work., Two mechanics and three fitters are .ployeli ink in addition one man is engaged whole

le on tyres:. The calibration of fuel pumps, cylinder poring and crankshaft grinding are done by outside las, but all other work is done in the Bath and Portland me firm's own garage. An engine is always kept ilt up for replacement as each vehicle is due in for major overhaul. This occurs at about 40,000 miles. ere is a partial overhaul at 20,000; oil is changed at 00 and fresh injectors are usually fitted at the same -iod. Wheel alignment (which, owing to the rough

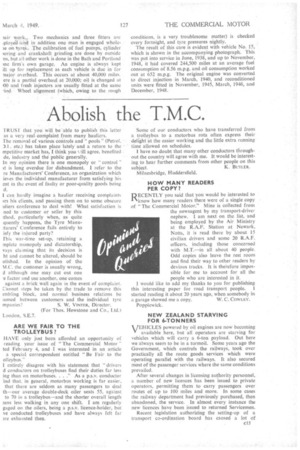

conditions, is a very troublesome matter) is checked every fortnight, and tyre pressures nightly. The result of this care is evident with vehicle No. 15, which is shown in the accompanying photograph. This was put into service in June, 1938, and up to November, 1948, it had covered 244,500 miles at an average fuel consumptiOn of 8.56 m.p.g. and oil consumption worked out at 652 m.p.g. The original engine was converted to direct injection in March, 1940, and reconditioned units were fitted in November, 1945, March, 1946, and December, 1948.