The miller's tale

Page 65

If you've noticed an error in this article please click here to report it so we can fix it.

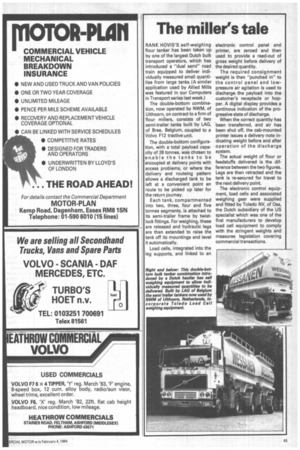

RANK HOVIS'S self-weighing flour tanker has been taken up by one of the largest Dutch bulk transport operators, which has introduced a "dual semi" road train equipped to deliver individually measured small quantities from large tanks. (A similar application used by Allied Mills was featured in our Computers in Transport series last week.) The double-bottom combination, now operated by NWM, of Uithoorn, on contract to a firm of flour millers, consists of two semi-trailer tanks built by LAG, of Bree, Belgium, coupled to a Volvo F12 tractive unit.

The double-bottom configuration, with a total payload capacity of 28 tonnes, was chosen to .e rta b I e the tanks to be encoupled at delivery points with access problems, or where the delivery and routeing pattern allows a discharged tank to be left at a convenient point en route to be picked up later for the return journey.

Each tank, compartmented into two, three, four and five tonnes segments, is attached to its semi-trailer frame by twistlock fittings. For weighing, these are released and hydraulic legs are then extended to raise the tank off its mountings and level it automatically.

Load cells, integrated into the leg supports, and linked to an electronic control panel and printer, are zeroed and then used to provide a read-out of gross weight before delivery of the desired quantity.

The required consignment weight is then "punched in" to the control panel and lowpressure air agitation is used to discharge the payload into the customer's receptacle or hopper. A digital display provides a continous indication of the progressive state of discharge.

When the correct quantity has been transferred, and air has been shut off, the cab-mounted printer issues a delivery note indicating weight before and after operation of the discharge system.

The actual weight of flour or feedstuffs delivered is the difference between the two figures. Legs are then retracted and the tank is re-secured for travel to the next delivery point.

The electronic control equipment, load cells and associated weighing gear were supplied and fitted by Toledo NV, of Oss, the Dutch subsidiary of the US specialist which was one of the first manufacturers to develop load cell equipment to comply with the stringent weights and measures legislation covering commercial transactions.