CEGB Scammells see radio-active service

Page 51

Page 52

Page 53

If you've noticed an error in this article please click here to report it so we can fix it.

Nuclear waste travels regularly on our roads. How? Safely? From where to where? Brian Weatherley, geiger counter at the ready, reports from Somerset

AN UNFORTUNATE by-product of nuclear power is highly radioactive nuclear waste, which takes the form of used uranium fuel rods. These must be taken from each of Britain's 11 nuclear power stations to the stringently controlled environment of the British Nuclear Fuels plant at Sellafield (formerly Windscale) in Cumbria, where they are reprocessed and made safe.

To get to Sellafield, the waste must be transported; this is potentially a highly dangerous process and much thought has gone into considering how it can be best be done.

Most of the waste is carried by British Rail in special containers from the power stations to Sellafield on purpose-built rail links but some of the power stations have to transport the waste by road to the nearest railhead.

One of the nuclear power stations that relies heavily on road transport in its waste removal process is Hinkley Point, which is situated on the Somerset coast about ten miles from Bridgewater.

To see how Hinkley Point's operator, the South Western Region of the Central Electricity Generating Board, carries out the road transport of its nuclear waste I visited the power station accompanied by the CEGB's regional transport engineer Martin Clark, who was responsible for specifying the vehicles currently used.

Transporting the waste is a strictly controlled process, with guidelines and regulations laid down by the International Atomic Energy (IAEA). Responsibility for ensuring compliance in the UK rests with the Department of Transport, and all hazardous nuclear products moved by road in the UK are subject to the Radioactive Substances (Carriage by Road) (Great Britain) Act of 1974.

For the CEGB, this means that all spent fuel elements must be carried in special heavy steel protective flasks, that are designed and tested in accordance with IAEA standards.

Weighing approximately 50 tons unladen, the flasks are essentially massive steel boxes with 368mm (141/2 inch) thick steel walls which contain the radioactivity.

Given the hazardous nature of the cargo, the flasks must be able to survive a number of accident tests, including a nine metre (30ft) drop onto a "nonyielding" surface, a free fall onto a solid steel punch from one metre (3ft), edge and corner angle impact tests, and the ability to withstand a constant 800 degree Centigrade fire for 30 minutes.

The tests are usually done on threequarter scale models, although full scale drop tests have been successfully carried out in America, where flasks have also survived derailment from a train at speeds up to 129km/h (80mph). In the UK the flask design is continually tested by the CEGB Structural Test Centre at Cheddar.

Before any of the metre-long spent fuel rods can be moved, they are first placed in a cooling pond where they are stored underwater for 90 days. This allows the elements to cool and lose some of their radioactivity.

The rods are then placed in an .open top steel container called a skip. The amount of radioactivity in any one skip will vary, although an overall limit is placed upon the amount of heat produced by the continuing process of radioactive decay.

The skip is then loaded under water or behind shielded handling facilities into the flask which is filled with approximately 250 gallons of water. After the lid bolts are secured, the flask seals are tested and the whole of the flask is thoroughly washed down to remove any radioactivity.

After being carefully checked, the flask, which can weigh up to 55 tonnes, is then ready to be transported by road the 12 miles from Hinkley to Bridgewater station.

To do this the CEGB operates two bonneted Scammell S24 6x4 tractive units plated up to 100 tons gvw, with special semitrailers.

Powered by Cummins NTE 350 turbocharged and chargecooled 14 litre engines rated at 243kW (326bhp), both vehicles are fitted with Allison Automatic HT 750 DRD gearboxes with torque convertors with a stall ratio of 2.13.

The reason for specifying the automatic boxes was that there had been problems with a manual Foden S75 6x4 previously used on the route. Although the 12 mile journey to Bridgewater is on A class roads with only slight gradients, if the vehicles stopped for any reason on the hills, restarting placed great loads on the clutch and driveline which led to very jerky pulling away from rest and a great deal of cab bounce. The problem was worsened by the presence along the route of a local farming co-operative, which has a constant traffic of incoming and outgoing tractors that sometimes baulked the CEGB vehicles.

Fitting the Allison unit on the Scammell with the built-in torque convertor allows the tractive units to pull away from rest easily on any section of the route without imposing undue strain on the driveline.

The two S24s have been further adapted to extended lowspeed operation by fitting twin radiators, each with its own fan and Kysor radiator shutters.

The two purpose-built flask low loaders that are currently operating were manufactured by Crane Fruehauf and have a design capacity of up to 60 tonnes each.

Previous semi-trailers that operated with conventional multileaf suspension and large wheels on the twin rear axles created a number of problems, particularly with the high axle loads imposed. So, on the new units Martin Clark opted for four axles with eight sets of smaller twin wheels giving a greater safety margin. The trailer bogies use a simple, sealed bearing rocking beam suspension similar to those fitted on tank transporters.

An overhead 157.5-tonne capacity gantry at the power station places the flasks on the trailers and they are fastened by four corner brackets. These brackets are designed to withstand a lateral force of up to 2g. and the close fit between the flask and the brackets, coupled with the high weight of the flasks, removes any need to secure them with chains or straps.

Having undergone the final check of radiation levels, the Scammell is ready to start the hour-long journey to Bridgewater accompanied by the usual police escort for any abnormal load.

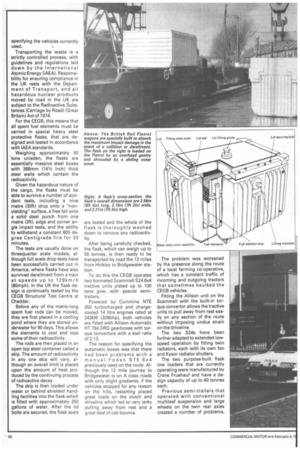

On arrival at the railhead, the flask is checked again by CEGB staff, and is lifted off by another overhead gantry which transfers it either directly to a British Rail Flatrol wagon or to a holding area. As soon as the flask is removed, it enters BR jurisdiction, and is subject to BR's own regulations covering the transport of atomic waste.

The Flatrol transporter which carries the flask is specially built to absorb most of the impact energy in the event of a collision or derailment. Despite the speed limit for goods trains recently being raised by British Rail to 60mph, a "nuclear" train still travels at the old limit of 40mph. Special scheduling is necessary for the journey to BNFL.

As well as the Scammell S24s, which on average make two laden runs to Bridgewater a week, the CEGB South Western Region also operates a Scammell 30.25 Constructor, which carries "low activity" waste, such as gloves, clothes, light plant and other material, in steel drums up to Sellafield twice a week.

Fitted with a Powell Duffryn Dinosaur container body, the eight-wheeler powered by a Rolls Royce 265 engine has replaced a vehicle previously operated by BNFL, and transports the low-activity waste generated by Hinkley, as well as by Oldbury and Berkeley nuclear power stations which are nearby.

Running such low mileages the flask vehicles have long operational lives, which leads to problems with model obsolescence and poor spares availability long before the vehicles have reached any operational mileage limit. Running only two journeys a week also creates a large amount of scheduled downtime, although occasionally the Scammells are used for non-nuclear abnormal movements by the CEGB.

The two Scammells are run on a daily basis by the Hinkley Point Power Station, which has its own maintenance facilities for all its vehicles. Any major operational problems with the vehicles are referred to Martin Clark at the regional office in Bristol.

Given the hazardous nature of the load, the CEGB understandably follows closely the movement of each flask. Apart from CEGB staff regularly monitoring the flasks, each of the Scammell drivers is specially trained to deal with breakdowns or minor accidents and the day cabs are fitted with two-way radios, ensuring instant moni

toring of the vehicles' movements. Like any other registered nuclear workers they also wear film badges that indicate the presence of any radioactivity If either of the Scammells were involved in an accident while travelling to Bridgewater that ruptured a flask, there are a number of contingency plans. The main one is the National Agreement for Incidents involving Radioactivity Scheme (NAIR), in which conventional emergency services are supplemented by specialist teams from the nearest nuclear establishment.

According to the CEGB, any water leaked from the flask would cause only mild contamination on the ground in the immediate vicinity, and this could be cleaned up with detergents and flushed away through the drains.

If a flask was split and some of the fuel rods inside damaged, it would be many hours before even the smallest amount of radioactivity was released into the air. A person standing 50 yards away, downwind of the flask for six hours, would receive a radiation dose of less than one fiftieth of what that person would receive from "natural" sources of radiation (such as soil, water, animals and plants) in a lifetime.

Although the probability of a serious accident to a flask "is estimated to be as little as one in ten million years," to quote official sources, the stringent transport safety measures reflect the approach to a process in which a single accident could be one too many.

Since 1962 there have been more than 7,000 flask journeys involving road and rail without one single incident. Today there are around 500 movements per year. During the same 20 years that the CEGB has been transporting flasks, 120,000 people were killed on the roads.

While all the safety statistics in the world will not win over the hardened critics of nuclear power, the safe and professional approach to the transport of nuclear waste should go some way towards reassuring the general public, particularly at a time when the CEGB has decided to build a new generation of pressurised water reactors similar to those in the Three Mile Island incident in America.