Van Hoc)l hands it to Al International

Page 45

Page 46

If you've noticed an error in this article please click here to report it so we can fix it.

As well as buses and coaches, the Belgian firm has a body and trailer company that has been pushing much work the way of this Essex firm. Bill Brock reports

OVER the past three years Al International Motor Engineering of Mundon near Maldon, Essex has developed a good working relationship with a Continental body and trailer company that is better known throughout the world for its bus and coach production.

Towards the end of 1983 a more formal arrangement was negotiated making Al sole agent for Van Hoot's commercial vehicle interests in the UK.

Al's activities include trailer manufacturing and repair in its own right and it is one of the few establishments to possess an American-made Bear chassisstraightening machine capable of realigning a 12.2m (40ft) trailer chassis without resorting to some type of heat application.

Recent changes in the maximum weight limit have prompted the company into offering tri-axle trailer conversions with an add-on leaf spring axle or the addition of a Neway air sprung axle.

At the other end of the spectrum Al provides an almost unique service in preparing show vehicles for major manufacturers. The cutaway Concept Cargo and Ford Transit, exhibited at Scotland and more recently at Geneva, are two examples of the engineering skills involved.

In the first six weeks of trading Al sold 30 trailers and quoted for 50 tanker trailers covering a wide range of specifications, including gas, ISO hazardous loads and general purpose.

Van Hool was established in 1947 by Bernard Van Hool and the company is still a family business, which is now managed by the founder's seven sons. From small beginnings at Koningshooikt in Belgium in some hangers left behind by American forces, the company rapidly developed and now occupies an 89-acre industrial complex, of which almost half is under cover, and employs 2,200 people who have produced more than 40,000 vehicles. Exports account for about 70 per cent of production, which is distributed to all parts of the globe.

Although bus and coach construction is still a large part of the company's activities, commercial vehicle production, which was started in 1964, is growing at a faster rate.

Eight years ago the purposebuilt commercial vehicle factory, covering 10 acres, was completed. Vehicles are mass-produced and designed to meet the wide range of legislative constraints imposed by the countries that are supplied.

Today the plant can produce five to seven buses and coaches and eight to 15 trailers and semi trailers every day.

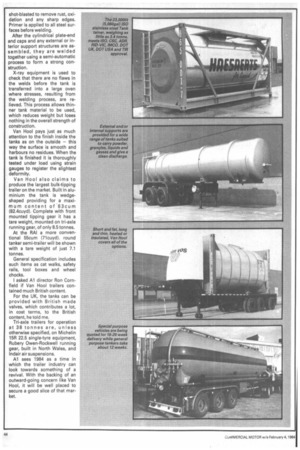

Van Hool prides itself on its contract with the operator and its research and development department acts upon the feedback of information received. The development department has a special duty when it comes to the design, construction, and testing of tank bodies that are made in steel, stainless steel and aluminium, to standard, insulated or pressurised designs.

Innovations usually involve years of work behind closed doors, and in a search to provide the best combination of maximum volume with the minimum tare weight, the latest materials and technology are employed.

Among Van Hool's exhibits at next week's RAI Amsterdam Show will be a high-pressure tank constructed to carry gas for National Dutch Transport. With

light materials and critical attention to design the unladen

weight is claimed to have been pared by 2,500kg (49.2cwt) which is equivalent to 5,000 litres (1,100 gallons) of the product being transported.

All metal components are shot-blasted to remove rust, oxidation and any sharp edges. Primer is applied to all steel surfaces before welding.

After the cylindrical plate-end and caps and any external or interior support structures are assembled, they are welded together using a semi-automatic process to form a strong construction.

X-ray equipment is used to check that there are no flaws in the welds before the tank is transferred into a large oven where stresses, resulting from the welding process, are relieved. This process allows thinner tank material to be used, which reduces weight but loses nothing in the overall strength of construction.

Van Hool pays just as much attention to the finish inside the tanks as on the outside — this way the surface is smooth and harbours no residues. When the tank is finished it is thoroughly tested under load using strain gauges to register the slightest deformity.

Van Hool also claims to produce the largest bulk-tipping trailer on the market. Built in aluminium the tank is wedgeshaped providing for a maximum content of 6 3curn (82.4cuyd). Complete with front mounted tipping gear it has a tare weight, mounted on tri-axle running gear, of only 8.5 tonnes.

At the RAI a more conventional 55cum (71cuyd). round tanker semi-trailer will be shown with a tare weight of just 7.1 tonnes.

General specification includes such items as cat walks, safety rails, tool boxes and wheel chocks.

I asked Al director Ron Cornfield if Van Hool trailers contained much British content.

For the UK, the tanks can be provided with British made valves, which contributes a lot, in cost terms, to the British content, he told me.

Tr-axle trailers for operation at 38 tonnes are, unless otherwise specified. on Michelin 15R 22.5 single-tyre equipment, Rubery Owen-Rockwell running gear, built in North Wales, and lndair air suspensions.

Al sees 1984 as a time in which the trailer industry can look towards something of a revival. With the backing of an outward-going concern like Van Hool, it will be well placed to secure a good slice of that market.