Full gas marks for NFC's Tankfreight

Page 36

Page 37

Page 38

If you've noticed an error in this article please click here to report it so we can fix it.

Wales Gas is the latest customer to benefit from the Harrogate firm's step up to the new weight limit. First-class service and competitive rates made it an attractive deal all round, reports John Durant

THE BULK movement and storage of powders, liquids and gases is a haulage area where 38 tonnes was always expected to be an attraction. This is proving to be the case with Tankfreight, part of the National Freight Consortium.

One area where Harrogatebased Tankfreight is moving ahead is in carrying liquefied petrolum gas. The company identified the potential for 38-tonne operation of lpg vehicles and decided to order tanks for this purpose.

Now two 38-tonne tri-axle road tankers have gone into service with Wales Gas for lpg hauls — the latest additions to Tankfreight's growing fleet of such vehicles.

The two tanks for this contract were built by Procor (UK) and have a water capacity of 42,990 litres {9,456 gal) and when fully loaded to 38 tonnes can carry approximately 19 tonnes of lpg. There are significant cost benefits to both Wales Gas and Tankfreight when this is compared to operating at 32 tonnes.

The two vehicles distribute lpg for Wales Gas requirements in South Wales and in the first full year of operation are expected to earn revenue in excess of £100,000.

"Two of the major factors infl u enci ng the award of the contract to Tankfreight were the assurances of a first-class service and the competitive rates that were negotiated by the commercially minded representatives of Wales Gas," Barry Partington, Tankfreight assistant marketing manager, told me.

"The ideal location of Tankfreight's depots and flexibility of local management was also of significance in ensuring that the initial phasing in of the operation ran smoothly and also to ensure the continued efficient working of the contract.

"When the contract was awarded the tanks were commissioned in record time and were into service with the customer literally within a matter of days."

In another field, says the company, more than 25 years experience of dealing with bulk molten sulphur has led to its "revolutionary design of 38tonne tankers."

These new 38-tonne barrels can carry between 23 and 24 tonnes of sulphur and because of their superb insulation can be discharged at destinations more than 300 miles away with minimal temperature loss.

The new breed is the third in line from the models used in 1958 when Tankfreight started carrying molten sulphur.

The latest update, according to Dennis Arnold, who is in charge of Tankfreight's sulphur contracts, has achieved perfection in that the product can be transported commercially with nil deterioration.

A total of four new rigs is on the road already, and it is anticipated that more will soon be commissioned. Having solved the problems of temperature loss over long distances, Tankfreight now believes it is way ahead of any other carrier in the molten sulphur market.

A major contract from Vinyl Products has been awarded on the basis of ability of offer an extremely economical all-round package.

Vinyl Products delivers waterbased vinyl resin from its factory at Warrington, throughout England and Scotland. With some high-viscosity products a single barrelful can take up to eight hours to load.

Tankfreight's solution was to pre-load overnight into one barrel and transport that during the next day, while meanwhile loading the next barrel so that the second barrel is ready to be collected when the empty tank is returned.

Tankfreight was also prepared to guarantee a minimum of nine journeys per week instead of the existing five, and provide suitably insulated tanks for the material, which must be maintained within strictly regulated temperature limits. The equipment, allocated on a three-year contract-hire basis, is three Volvo F7 tractive units and six 5,000 gallon stainless steel twincompartment barrels.

Tankfreight grew from the amalgamation in 1978 of Pickfords Tank Haulage, Caledonian Bulk Liquids and Harold Wood. In the case of Cray Valley Products it has been moving its synthetic resin base in bulk for 11 years — around an annual 13,000 tonnes from Immingham to all parts of the country.

Loading the thick, syrupy liquid may take as long as eight hours for a 20-tonne insulated, stainless steel barrel, so Tankfreight supplies more barrels than tractive units and has got up to nine deliveries per vehicle per week.

Alan Aplin, Immingham manager, commented: "Although our contract is reviewed periodically, it seems unlikely that a better solution will occur."

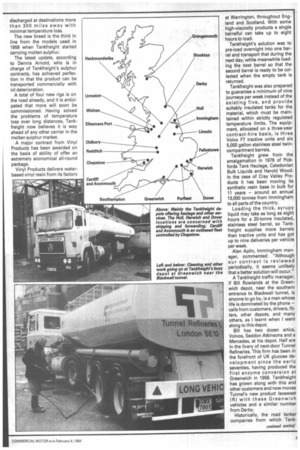

A Tankfreight traffic manager, if Bill Rowlands at the Greenwich depot, near the southern entrance to Blackwall tunnel, is anyone to go by, is a man whose life is dominated by the phone — calls from customers, drivers, fitters, other depots, and many others, as I learnt when I went along to this depot.

Bill has two dozen artics, Volvos, Seddon Atkinsons and a Mercedes, at his depot. Half are in the livery of next-door Tunnel Refineries. This firm has been in the forefront of UK glucose development since the early seventies, having produced the first enzyme conversion at Greenwich in 1958. Tankfreight has grown along with this and other customers and now moves Tunnel's new product lsosweet (R) with these Greenwich vehicles and a similar number from Derby.

Historically, the road tanker companies from which Tankcontinued overleaf freight grew — as part of the National Freight Consortium operating 13,000 vehicles from 700 locations in Britain and several overseas — were heavily involved in chemical and petroleum haulage.

Plans were formulated in the late seventies to move into bulk food distribution.

Today, Tankfreight has more business in moving bulk liquids and powdered food products than in any other market sector.

British Sugar, for instance, has bulk liquid sugar distributed by Tankfreight vehicles and drivers from a factory in Bardney, near Lincoln, to customers in the Midlands and North of England.

Tankfreight carries everyday foodstuffs in bulk — besides sugar, milk, glucose, starch and beer, which must all meet stringent hygiene demands.

It can offer customers various packages: long/medium/shortterm hire of tankers and drivers; agreements/contracts of affreightment (hiring a ship to carry cargo); tank conversion to 'tri-axle 38-tonne standards including stretching; tank refurbishment; degassing; engineering; and fitting of ancillaries. Customers who want to retain their own tractive units and drivers are supplied with tanks in their own livery.