100 b.h.p. Oil Engine Produces 150 b.h.p. When Operating as

Page 38

Page 39

Page 40

Page 41

If you've noticed an error in this article please click here to report it so we can fix it.

a Petrol injection Untt. Overdrive Gear Ratio Employed on Latest 14-15-tonner

Excellent Acceleration and High Average Speeds Obtainable With Petrol Consumption at the Rate of 6.32 m.p.g. Vehicle Cruises at 40 m.p.h. IN keeping with the policy of giving our readers the first news of all, important developments in the industry, we are now able to publish a road-test report of what is believed to be the first petrol-injection-engined commercial vehicle to go into production in the world. It is a product of John I. Thornycroft and Co., Ltd., Basingstoke, and the road test was conducted with the engine fitted in the maker's 14-15-ton Trusty-class chassis—a maximum-load eight-wheeler.

The essential differences between the oil-engined vehicle and the petrol-injection machine are concerned with the cylinder head and pistons, the fuel injection equipment and the gearbox arrangements, to which specific reference will be made as they arise in the

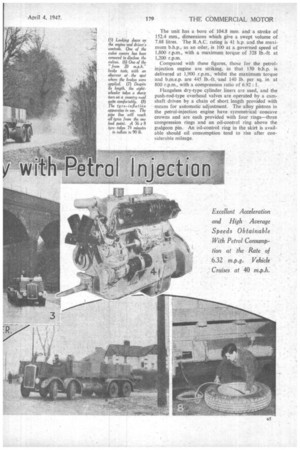

specification. • It should be pointed out that the Trusty 14-15-tonner is produced as a six-cylindered direct-injection oiler, and that the engine specification of the petrol-injection Unit is basically identical, the main difference being in the cylinder head, pistons and injection equipment, as previously mentioned. ' The unit has a bore of 104.8 mm. and a stroke of 152.4 mm., dimensions which give a swept volume of 7.88 litres. The R.A.C. rating is 41 h.p. and the maximum b.h.p., as an oiler, is 100 at a governed speed of 1,800 r.p.m., with a maximum torque of 328 lb.-ft. at 1,200 r.p.m.

Compared with these figures, those for the petrolinjection engine are striking, in that 150 b.h.p. is delivered at 1,900 r.p.m., whilst the maximum torque and b.m.e.p. are 445 lb.-ft. 'and 140 lb. per sq. in at 800 r.p.m., with a compression ratio of 6.92: 1.

Flangeless dry-type cylinder liners are used, and the push-rod-type overhead valves are operated by a camshaft driven by a chain of short length provided with means for automatic adjustment. The alloy pistons in the petrol-injection engine have symmetrical concave crowns and are each provided with four rings—three compression rings and an oil-control ring above the gudgeon pin. An oil-control ring in the skirt is available should oil consumption tend to rise after considerable mileage.

The injector is so mounted in the cylinder head as to bring the nozzle to within about f in of the back of the inlet valve, which opens 10 degrees before t.d.c., whilst fuel injection commences 10 degrees after t.d.c. It will be noted from accompanying diagrams that, whereas the inlet valve opening period covers 140 degrees, the dura tion of injection at maximum power output of the engine is but 80 degrees, this being during the first half of the downward stroke of the piston, when the air speed through the inlet valve is at its highest.

The fuel-injection equipment employed has been developed by the C.A.V Research Department, in close co-operation with Mr W S Dack, chief of the Thorny croft experimental departmentThe equipment comprises an injection pump, automatic mixture control, excess fuel device for starting, feed nump, filter and injectors The charge is, of course, spark-ignited, a special high-voltage coil being used; the automatic advance being a function of both engine speed and throttle position.

Reverting to the general specification of the chassis, the drive from the engine is taken by a single dry-plate clutch to a unit-constructed gearbox providing the normal four forward speeds and a reverse. In the case of the oiler there is an auxiliary gearbox which affords an additional range of ratios, whilst on the petrol-injection chassis there is a normal gearbox and a modified set of gears in the auxiliary gearbox, giving an over-speed ratio The main ratios, which apply to both chassis, are 1, 1.56, 2.75 and 5.13 to 1, and 7.69 to 1 reverse. The auxiliary gearbox ratios on the oiler are 1.88, 2.93, 5.17, 9.64 to 1, and 14.45 to 1 reverse. The over-drive on the petrol chassis has a ratio of 795 to 1, which gives a road speed of 40.2 m.p.h. at 1,800 r.p.m of the engine.

Open tubular-type propeller shafts, with needle-roller universal couplings, take the drive to the first overheadworm-driven axle, a third universally jointed shaft taking the drive to the rear axle of the bogie.

To reduce tyre wear and to ensure a correct distribution of drive to all wheels, a third differential is incorporated in the foremost axle of the bogie.

Semi-elliptic springs are used for suspension, those on the rear bogie being arranged in pairs and inverted; they are pivoted at their centres to brackets attached to the chassis frame. The method of mounting the springs to the axles is by ball-type trunnions which permit of independent movement of the wheels without causing twisting moments to be transmitted to the frame; the latter, which is of pressed steel, has a depth of 11 ins.

Driving and braking torque for each axle are transmitted through an I-section radius arm coupled to the centre cross-tube of the bogie by a link fitted with flexible rubber bushes.

An interesting feature. of the braking system is that the shoes are applied by air pressure on all eight wheels, air pressure being supplied by a compressor, through an unloader valve, to two reservoirs and then to the foot valve Incidentally, the same air-pressure supply is utilized to inflate the tyres; a 36-in by 8-in. tyre can be inflated to a pressure of 90 lb per sq in. in 7i minutes with the engine hand-set to run at 1,100 r.p.m.

In view of the character of this road test, we departed somewhat from our usual procedure Mr. Dack, who has been responsible for the development of the Thornycroft petrol-injection engine, wished that we should test certain features of the oiler conjointly, so that we might the better be able to appreciate the difference in performance between the two types. It must be made clear, however, that the petrol-injection-engined vehicle has not been developed specifically for the home market, and any remark which we may make relative to the superior performance of the petrol chassis, as compared

with that of the oiler, is not intended to belittle the latter, which is undoubtedly a machine having an exceptionally good performance in its particular category

We made our first run out from the Thornycroft works at Basingstoke on the oiler, our objective being Overton, which is about seven miles from the works. This run includes several useful hills, which mean collar work for a fully laden maximum loader On the oiler we dropped down to normal second and pulled steadily at about 6 m.p.h. on one of these climbs, the petrol chassis, meantime, waiting for the signal to overtake.

When the driver was waved on, the manner in which the machine, also fully laden, overtook us left little doubt regarding the accuracy of the b.h.p. curve of the engine. We made the return journey, from Overton to the works, on the petrol chassis, and we were quick to note a number of important differences, quite excluding the fact that the oiler had a cab and the petrol chassis had not! •

The first point, of course, is the comparative silence of the petrol engine, making full allowance for the fact that there was no cab to act as a sounding board. Then

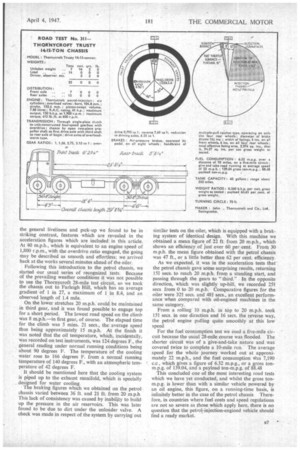

the general liveliness and pick-up we found to be in striking contrast, features which are revealed in the acceleration figures which are included in this article. At 40 m.p.h., which is equivalent to an engine speed of 1,800 r.p.m., with the overdrive ratio engaged, the going may .be described as smooth and effortless; we arrived back at the works several minutes ahead of the oiler.

Following this introduction to the petrol chassis, we started our usual series of recognized tests. Because of the prevailing weather conditions it was not possible to use the Thornycroft 28-mile test circuit, so we took the chassis out to Farleigh Hill, which has an average gradient of 1 in 27, a maximum of 1 in 8.4, and an observed length of 1.4 mile.

On the lower stretches 20 m.p.h. could be maintained . in third gear, and it was found possible to engage top for a short period. The lowest road speed on the climb was 8 m.p.h.—in first gear, of course. The elapsed time for the climb was 5 mins. 21 secs., the average speed thus being approximately 15 m.p.h. At the finish it was noted that the oil temperature, which, incidentally, was recorded on test instruments, was 124 degrees F., the general reading under normal running conditions being about 90 degrees F. The temperature of the cooling water rose to 166 degrees F. from a normal running temperature of 140 degrees F., with an atmospheric temperature of 42 degrees F.

It should be mentioned here that the cooling system is piped up to the exhaust manifold, which is specially designed for water cooling. The braking figures which we obtained on the petrol chassis varied between 36 ft. and 21 ft. from 20 m.p.h This lack of consistency was caused by inability to build up the pressure in the air reservoirs. This was later found to be due to dirt under the unloader valve. A check was made in respect of the system by carrying out similar tests on the oiler, which is equipped with a braking system of identical design. With this machine we obtained a mean figure of 22 ft. from 20 m.p.h., which shows an efficiency of just over 60 per cent. From 30 m.p.h. the mean figure obtained with the petrol chassis was 47 ft., or a little better than 62 per cent. efficiency.

As we expected, it was in the acceleration tests that the petrol chassis gave some surprising results, returning 151 secs. to reach 20 m.p.h. from a standing start, and passing through the gears to "third." In the opposite direction, which was slightly up-hill, we recorded 253 secs from 0 to 20 m.p.h. Comparative figures for the oiler were 32/ secs. and 48i secs., an excellent performance when Compared with oil-engined machines in the same category.

From a rolling 10 m.p.h. in top to 20 m.p.h. took 1.51 secs. in one direction and 16 secs. the reverse way, the petrol engine pulling quite smoothly at this low speed For the fuel 'consumption test we used a five-mile circuit because the usual 28-mile course was flooded. The shorter circuit was of a give-and-take nature and was covered twice to complete a 10-mile run. The average speed for the whole journey worked out at approximately 22 m.p.h., and the fuel consumption Was 7,190 c.c , which gives a figure of 6.32 m.p.g., or a gross tonm.p.g. of 139.04, and a payload ton-mpg. of 88.48 This concluded one of the most interesting road tests which we have yet conducted, and whilst the gross tonm.p.g. is lower than with a similar vehicle powered by an oil engine, this figure, on a running-time basis, is infinitely better in the case of the petrol chassis Therefore, in countries where fuel costs and speed regulations are not so severe as those which apply here, there is no question that the petrol-injection-engined vehicle should find a ready market.