OVERCOOLING A/114,s

Page 32

Page 33

If you've noticed an error in this article please click here to report it so we can fix it.

viean INEFFICIENCY How the Adverse Effects of Low-temperature Running May be Overcome. The Appltcation of Steam Cooling to Commercial Vehicles

By R. W. BENT, A.M.1.Mech.E., M.I.A.E.

THE conventional cooling system, in which a radiator, pump and, of course, water jackets, are employed, may be considered as reasonably satisfactory, and, provided that loss of water be made good, and precautions taken to prevent freezing, it will fulfil its chief function of preventing overheating of the engine.

li the laudable desire to avoid the ill effects of overheating, some designers have provided cooling systems which do not permit the engine to operate at an e4Acient temperature. It must never be forgotten that a petrol or oil engine is a heat engine, so that any subtraction of heat by cooling results in a direct loss of efficiency. It would be better to regard the cooling system as a heat controller which regulates the temperature within close limits.

• A Misnomer

Although we speak of "water cooling," it is, of course, the air that finally dissipates the heat, the water merely being a means for transferring the heat from the cylinder block to the radiator. This raises the point s to whether direct air cooling is a possibility for commercial-vehicle power units.

Usually, air cooling is associated with small units, such as motorcycles, but it has, of 'course, been used on quite large aircraft engines and on some road vehicles. Its obvious advantages of reduced weight and cost, rapid warming up, and freedom from icing troubles, are at once apparent. The difficulties arise when one attempts to apply the system to the conventional in-line engine.

Whatever system of forced draught be used, unequal cooling of the cylinders is almost bound to occur. Another point is that water-jackets form a useful sound insulator, and although a little extra noise might not be too serious on goods vehicles, it would be a definite drawback on passenger vehicles.

9

General Principles

The general principle on which the capacity of the cooling system is based, is that boiling shall not occur under the most adverse conditions. For this purpose a figure, known as the critical air temperature, may be taken, which is the maximum atmospheric temperature at which the vehicle may be driven without boiling occurring Obviously, this temperature will vary with the load and speed, and tests are best carried out at constant speed on a circular track, so that the effect of wind is automatically cancelled out.

as the power. Thus, an engine developing 100 b.h.p. will have about twice the amount of heat to dissipate as compared with a 50 b.h.p. engine. It is obvious that it is not possible to use a radiator of twice the frontal area, but the problem can be met by increasing the rate of water circulation, using radiator tubes of greater depth, and employing a larger fan.

The temperature of 100 degrees F. is, of course, exceeded in some countries overseas, but this is, to some extent, compensated by the lower speeds which can be achieved on inferior roads. Manufacturers, generally, increase the cooling capacity of vehicles which are likely to operate in hot climates.

Turning now to the actual heat lost by the cooling water, Fig. 1 shows a

typical heat-distribution chart for (a) petrol-and (b) oil engines. It will be noted that the loss in the case of the oil engine is less than for the petrol unit, but even here it represents more than one quarter of the total heat supplied to the engine. Most of this loss is inevitable, but the cooling losses increase if the engine be operated at anything below its optimum temperature.

Consumption and Head

One of the effects of cool running conditions is shown in Fig. 2, which represents the average fuel consumption of a fleet of oil-engined vehicles for a year.. The lower average dur-ing the winter months can be partly accounted for by the inferior road conditions and operating hazards, but a good deal of it is caused by the lower air temperatures in which the engines are operating.

Colder weather will, for example, necessitate a longer warmingup period, a point on which the oil engine apparently scores. The word " apparently " is used advisedly, as although the oil engine will accept loads almost immediately after starting from cold, this may mask the fact that it is operating in an over-cooled condition.

Apart from the increased fuel consumption, cool running also brings other ill-effects in its train, such as reduced lubrication efficiency, and dilution. Crankcase dilution occurs in both petrol and oil engines, and when prolonged cool running is indulged in, can reach serious proportions.

Quick Warming Up

A thermostat is an asset in ensuring rapid warming up, and maintaining a coolant temperature within reasonable limits. Most thermostats work on the bellows principle, the latter containing methyl alcohol or acetone, which have low boiling points. As the temperature rises the bellows expands opening a valve and restoring the normal water circulation. The thermostat can be applied in three ways: (a) controlling radiator shutters, (b) short-circuiting the radiator completely, and (c) as a bypass.

Type a has been applied to some cars, but it suffers from the extra complication of movable shutters, and the fact that undue friction in these will vary the point at which the thermostat operates. It does, however, avoid the risk of the radiator's contents freezing, as the whole of the water is in circulation.

Thermostat Action

Type b is arranged in the top water pipe, where, when shut, it prevents the water from passing to the radiator. As the water is retained in the cylinder block, rapid warming up is assured, but without blanking off the radiator, freezing may occur if the vehicle be run with cold air passing through the stagnant water in the radiator.

Method c is probably the most popular. With this a by-pass pipe runs from the thermostat casing to the water-pump inlet, or radiator. A • small flow of water is allowed to take place with the valve closed, thus permating a steadier operation of the thermostat, as high pressures cannot be built up in the cylinder block. The by-pass pipe must be small, otherwise the warming-up period will be unduly prolonged.

By-pass Arrangement

A further modification of this type is to arrange for the by-pass port to he closed when the main valve opens. This permits all the water to circulate through the radiator when the engine is hot, and thereby ensures maximum cooling.

The efficient operating temperature of the cooling water is normally taken as 170-180 degrees F. Although most engines will run satisfactorily With higher coolant temperatures, it is found that the loss caused by steaming becomes excessive if higher temperatures be permitted. Nevertheless, there is a direct gain in efficiency if the engine be run at higher temperatures, as cooling losses are reduced. One or two makers have utilized this fact by designing their cooling systems to operate at pressures above atmospheric.

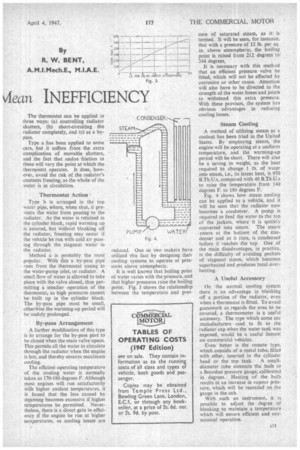

It is well known that boiling point of water varies with the pressure, and that higher pressures raise the boiling point. Fig. 3 shows the relationship between the temperature and pres

sure of saturated steam, as it is termed. It will be.seen, for instance, that with a pressure of 12 lb. per sq in. above atmospheric, the boiling point is raised from 212 degrees to 244 degrees.

It is necessary with this method that an efficient pressure valve be fitted, which will not be affected by corrosion or other cause. Attention will also have to be directed to the strength of the water hoses and joints to withstand this extra pressure. With these provisos, the system has obvious advantages in reducing cooling losses.

Steam Cooling • A method of utilizing steam as a coolant has been tried in the United States. By employing steam, the engine will be operating at a uniform temperature, and the warming-up period will be short. There will also be a saving in weight, as the heat required to change 1 lb. of water into steam, i.e., its latent heat, is 970 B.Th.U.s, compared with 40 B.Th.U.s to raise the temperature from 140 degrees F. to 180 degrees F.

Fig. 4 shows how steam cooling can be applied to a vehicle, and it will be seen that the radiator now becomes a condenser. A pump is required to feed the water to the top of the jackets, where it is quickly converted into steam. The steam enters at the bottom of the condenser and as it rises, is condensed before it reaches the top. One of the main disadvantages, in practice, is the difficulty of avoiding pockets of stagnant steam, which becomes superheated and produces local overheating.

A Useful Accessory

On the normal cooling system there is an advantage in blanking off a portion of the radiator, even when a thermostat is fitted. To avoid guesswork as regards the area to be covered, a thermometer is a useful accessory. The type which some car manufacturers used to fit to the radiator cap when the water tank was exposed, would be a useful fitment on commercial vehicles.

Even better is the remote type, which consiSts.of a metal tube, filled with ether, inserted in the cylinder head or the top tank. A smalldiameter tube connects the bulb to a Bourdon pressure gauge, calibrated in degrees. Heating of the bulb results in an increase in vapour pressure, which will be recorded on the gauge in the cab.

With such an instrument, it is possible to adjust the degree of blanking to maintain a temperature which will ensure efficient and economical operation.