Hands-aff

Page 40

Page 41

If you've noticed an error in this article please click here to report it so we can fix it.

espraticons

Technology has advanced so fast that it is now possible for the driveline of a modern truck to be maintenance-free for 500,000km, or three years. But is it desirable?

Long-life engines are nothing new. But it is only when you stand back that you

. can appreciate what truck engineers have achieved in terms of durability and dayto-day reliability of the vehicle driveline.

Graham Swan, Cummins' customer support manager, reports that many 10-litre L10 engines exceed one million kilometres before a first major overhaul, and points to some, such as those in Morrisons'1,10-eng-ined ERF tractors, which have covered 1.51 and 1.92 million kilometres before a major overhaul.

Modern engines are managed electronically and, increasingly, that applies to more than just the fuelling.

Mercedes-Benz says: "It is an integral part of the overall vehicle electronics, and contributes substantially to quality assurance because it is capable of detecting malfunctions at an early stage."

+ Engines react to malfunctions In the case of the new Mercedes-Benz 500 series used in the Actros, the engine management system stores some 120 "maps" which describe and define desirable as well as critical engine conditions.

Sensors monitor the condition of the engine more than 60 times a second to pinpoint defects almost immediately.

The maps are programmed with extensive protective functions so that the fuelling can be cut back to reduce the torque output if the coolant temperature or engine speed exceeds a pre-set limit.

Such smart engines can also take account of inputs such as the number of cold starts, oil temperature and when they need servicing. Alternatively, the Actros Telligent servicing system displays the work needed, so that the operator can decide whether to deal with it immediately or at a pre-determined service interval.

+ Superior synthetic oils

The value of these electronic niceties would be much reduced were it not for tremendous advances in oil technology which allow oil drain intervals of up to 160,000km. Many modern hydrocracked mineral oils meet the ACEA E3 classification, which is suitable for 100,000Icm drain intervals, while the ultimate performance of synthetic oils meeting the ACEA E4 classification has yet to be fully exploited.

Though cleared for up to 160,000km by some manufacturers, a number of test vehicles have surpassed the 500,000km mark without incurring undue wear. Synthetic oils have a much-reduced top-up requirement, but operators looking for long drain intervals still need to be sure that their oil levels are maintained.

Oil level indicators are available, but Groeneveld goes further with its Oilmaster product which provides fully automatic oil level control. The kit comprises a 12-litre oil tank with an

integrat

ed pump controlled by a level sensor located in the sump.

Each time the vehicle stands for more than 30 minutes with the ignition switched on the oil level is automatically checked and, if need be, a pre-determined amount of oil is pumped into the sump. A pilot light on the dash indicates that this has happened, and also warns of any equipment malfunction.

If engines are complex, clutches are decidedly simple, but are equally key to a maintenance-free truck. Traditionally, long-life/ heavy-duty performance could only be achieved by twin-plate designs — and, in the main, these also needed to be manually adjusted. Eaton has made a breakthrough, however, by substantially improving the life of its 430mm, self-adjusting, single-plate, diaphragm clutch. In earlier designs the diaphragm spring changed position as the facing wore down, and ultimately restricted further compensation. In the new design, the position of the spring remains constant regardless of wear, allowing the wearing face thickness to be increased from 3mm to 5mm and extending its working life by 66%.

+ Long-life transmissions

Transmission life has improved dramatically over the past 10 years. Constant-mesh transmissions used to outlast synchromesh transmissions, but now both types are reliable and can run to 300,000km and beyond between oil changes. Eaton has recently approved the use of synthetic lubricants for its S-series transmission for oil change intervals of up to 300,000km.

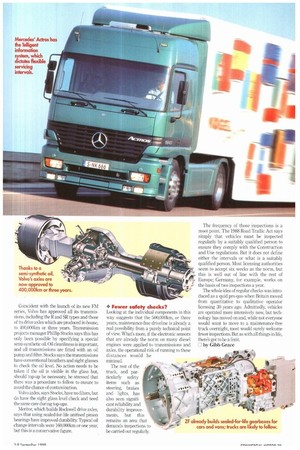

ZF already produces sealed-for-life car transmissions, but says there is a growing pressure from CV manufacturers for an equivalent. Surprisingly, perhaps, ZF says it would not be difficult from a function and wear point of view. The main problem, it sees, is controlling water ingestion as a result of steam cleaning or air-borne moisture, both of which enter through the breather. It is impossible to do away with the breather as pressure build-up in the box could damage seals. Current a transmissions have maximum oil changes of 90,000km with mineral oil and 300,000km or two years on synthetics. In response to manufacturer requests, ZF is looking at running to 500,000 km over three years on synthetics, but has yet to sign off products to that level. Coincident with the launch of its new FM series, Volvo has approved all its transmissions, including the Rand SR types and those of its drive axles which are produced in-house, to 400,0001mi or three years. Transmission projects manager Phillip Stocks says this has only been possible by specifying a special semi-synthetic oil. Oil cleanliness is important, and all transmissions are fitted with an oil pump and filter. Stocks says the transmissions have conventional breathers and sight glasses to check the oil level. No action needs to be taken if the oil is visible in the glass but, should top-up be necessary he stressed that there was a procedure to follow to ensure to avoid the chance of contamination.

Volvo axles, says Stocks, have no filters, but do have the sight glass level check and need the same care during top-ups.

Meritor, which builds Rockwell drive axles, says that using sealed-for-life unitised pinion bearings have improved durability Typical oil change intervals were 160,000km or one year, but this is a conservative figure. • Fewer safety checks?

Looking at the individual components in this way suggests that the 500,000km, or three years, maintenance-free driveline is already a real possibility from a purely technical point of view What's more, if the electronic sensors that are already the norm on many diesel engines were applied to transmissions and axles, the operational risk of running to these distances would be minimal.

The rest of the truck, and particularly safety items such as steering, brakes and lights, has also seen significant reliability and durability improvements, but this remains an area that demands inspections to be carried out regularly. The frequency of those inspections is a moot point. The 1988 Road Traffic Act says simply that vehicles must be inspected regularly by a suitably qualified person to ensure they comply with the Construction and Use regulations. But it does not define either the intervals or what is a suitably qualified person. Most licensing authorities seem to accept six weeks as the norm, but this is well out of line with the rest of Europe; Germany, for example, works on the basis of two inspections a year.

The whole idea of regular checks was introduced as a quid pro quo when Britain moved from quantitative to qualitative operator licensing 30 years ago. Admittedly, vehicles are operated more intensively now, but technology has moved on and, while not everyone would want to move to a maintenance-free truck overnight, most would surely welcome fewer inspections But as with all things in life, there's got to be a limit.

El by Gibb Grace