KEEP THE OIL CLEAN D SAVE THE ENGINE

Page 26

Page 27

If you've noticed an error in this article please click here to report it so we can fix it.

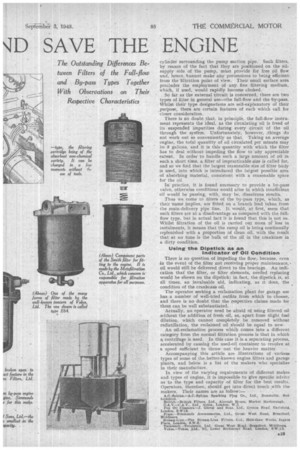

Stressing the Importance of Keeping the Sump Oil Free from Foreign Matter and the Means By Which This Can Be Satisfactorily Achieved The Outstanding Differences Between Filters of the Full-flow and By-pass Types Together With Observations on Their Respective Characteristics

IN view of the increased interest which is being shown in the subject of oil recovery and filtration generally, it would seem that a review of the principles involved, and the means employed, would'not be inopportune. The subject of oil reclamation ha always been the cause of much controversy, which is somewhat difficult to understand when there is so much evidence available to prove that the process Is perfectly logical and economical. There are some people who assert that oil definitely wears out and, therefore, should not be recovered and used over and over again.

The present writer spent many years with two of the better-known Oil concerns its this country, and thus has had an opportunity of finding out the views held by people whose business it is to sell oil.

Despite the obvious fact that oil-recovery schemes are not In the best interests of increased oil sales, company No. 1 was, at all times, willing to give users of its products the benefit of its experience, even to the extent of advising on filter types, general, maintenance and so on.

Not so with company No. 2, which held the ,view that filtered oils should not again be used in an internal-combustion engine, and said it was not suitable for any more exacting duty than for use on line shafting. The fact that numerous stationary units throughout the country were running with filters inbuilt in the engines made no difference to this attitude.

As may be known, this same view: it held in some " high' places," but, be that as it may, one has not to travel far to refute such old-fashioned ideas. There is proof to be had in plenty that oil recovery is not only practicable but highly desirable from the economy aspect, and oil filtration, from the point of view of preventive maintenance.

Looking at the stibject broadly, there are two methods which may be followed—bulk filtration of crankcase drainhags in a large-capacity garage plant, or the use of afull., flow or by-pass filter on the engine Whilst bulk filtration definitely shows a direct saving on the, annual oil bill and should be practised in all cases where the number of vehicles operated justifies the initial outlay on the plant, it should not be looked upon as a reason for not fitting a filter, or filters, to each individual engine.

Bulk Filtration Does Not • Supplant Engine Fitters With a garage plant it is reasonable to assume that engine crankcases would be drained at more frequent intervals, in the krfowledge that the greater percentage of the oil treated will be used again; but contamination begins within the first half-an-hour of the engine being started. and, without an engine filter, will be running with dirty oil for 2,000 or more miles. The ideal arrangement, then, is a combination of the two systems in, the case of big fleets of vehicles, or only engine filters where the more-expensive garage plant is ruled out.' .

It may be as well at this stage to mention that the normal type of engine filter does not reckon to cope with fuel dilution of the crankcase oil, but, indireetly, it should reduce such dilution, because the better the general condition of the lubricating oil the greater chance is there of maintaining the piston seal in the engine. With an engine In good mechanical condition. however, fuel dilution does not reach a maximum high figure, and, even so, such dilution as does occur becomes more or less stabilized as the result of the petrol being re-evaporated under running conditions.

In the. case of an oil engine, should dilution be present, the conditions are different, as the heavier nature of the diluent prevents it being driven off. More frequent drainage is called for in such cases, but, in practice, it is found that dilution of the crankcase oil in oil engines represents a negligible figure and has little or no effect upon the lybrirating properties of the oil.

An engine filter, then, is designed to deal with the more or less solid contaminating Particles, consisting of subsolids, carbon and ash, a high percentage of iron oxide being contained in the last-named.

The first stage in preventing foreign matter from entering the circulating system is to provide a filter in the sump itself, either of the floating type or in the form Of a gauze A24

cylinder surrounding the pump suction pipe. Such filters, by reason of the fact that they are positioned on the oilsupply side of the pump, mast provide for free oil flow. and, hence, taut make any pretensions to being efficient from the 'filtration point of view. Their small surface area precludes the employment of any fine flltering medium, which, if used, would rapidly become choked.

So far as the external circuit is concerned, there are two types of filter in general use—.-the full-flow and the -by-pass. Whilst their type designations are sell-explanatory of their • purpose, there. are certain features of each which call 'for closer consideration.

There is no doubt that, in principle, the full-flow instrument represents the ideal, as the Circulating oil is freed of its suspended impurities during every circuit of the oil through the system. Unfortunately, however, .things do not work out so conveniently as that. Taking an average engine, the total quantity of oil circulated per minute may be 3 gallons, and it is this quantity with which the filter has to deal without impeding the flow to any appreciable extent. In order to handle such a large amount of oil in such a short time, a filter of impracticable sizeis called for, and so we find that the largest reasonable size of filter body is used, into which is introduced the largest possible area of absOrbing material, consistent with a reasonable space

• for the oil.

In practice, it is found necessary to provide a by-pass valve, otherwise conditions would arise in which insufficient oil would be passing, with, may be, disastrous results.

Thus we come to filters of the by-pass type, which, as their .name implies, are fitted on a branch lead taken from the main-delivery pipe line. It would, at first, seem that such filters are at a disadvantage as compared with the fullflow type, but in actual fact it is found that this is not so. Whilst filtration of the oil is carried out more of less in instalments, it means that the sump oil is being continually replenished with a proportion of clean oil, with the result that at no time is the bulk of the oil in the crankcase in a dirty condition.

Using the Dipstick as an Indicator of Oil Condition There is no question of impeding the flow, because, even In the event of the filter not receiving proper maintenauce,• oil would still be delivered direct to the bearings. An indication that the filter, or filter elements, needed replacing would be shown on the dipstick: in fact, the dipstick is, at all times, an invaluable aid, indicating, as it does, the condition of the crankcase oil.

The operator seeking a reclamation plant for garage use has a number of well-tried outfits from which to choose, and there is no doubt that the respective claims made for them can be well substantiated. .

Actually, no operator need be afraid of using filtered oil without the addition of fresh oil, as,. apart from slight fuel dilution, which cannot completely be removed without redistillation, the reclaimed oil should be equal to new.

An oil-reclamation process whiCh comes into a different category from the normal filtration process is that in which a centrifuge is used. In this case it is a separating process, accelerated by causing the used-oil container to revolve at a speed sufficient to throw out the heavier matter.

Accompanying this article are illustrations of Various types of some of the.better-known engine filters and garage plants, and below, is a list of the makers who specialize in their manufacture.

In view of the varying requirements of different makes and types of engine, it is impossible to give specific advice' as to the type and capacity of filter for the best results. Operators, therefore, shotild get into direct touch with the makers. Their names are as follow:—

8parking Plug Co. Ltd.. Durtstahle, Bed B ritish.—Briash Filters, Ltd., Aireril House, Market Harhorough, C.A.V.—C.A.V., Ltd. Acton, London, W.3. Vox Oil Cleaners.—. Glover and Sons, Ltd:. Groton Road, LarisfieLd, London, S.W1B.

Fram.---Simmonds Acroecasories, Ltd., Great West Road, Brentford, Middlesex.

S tr.eara-Line.—ne Stream Line Filters, Ltd., Hele-shaw Works, Inge Le Place, London,. 8.W.8. • Tecalemit,—Tecalemit, Ltd. Great-West Road, Brerntford, Middlesex. Vokes.—Volase, ,Ltd., 95, Lower Richmond Road. London, S.-W.18.