What to Do in Emergencies.

Page 17

Page 18

If you've noticed an error in this article please click here to report it so we can fix it.

During the present state of affairs, we shall substitute this new feature for our usual "Drivers' and Mechanics' Contributions"; these we shall resume when more normal circumstances rule in our industry. We repeat our recent statement, that we are desirous of assisting the "new man at the wheel." of whom there are many at the present time for one reason or another. Our usual "D. and M." pages have included many lips as to workshop procedure, etc. ; these we are temporarily dropping, whilst we are selecting more appropriate Suggestions with

care. Drivers and mechanics may still send in contributions, which will be paid for at the usual rates.

Can be Used Instead of a Pit.

Inspection pits are expensive to construct, sometimes becoming a receptacle for congealed mud and grease; they are somewhat difficult to keep clean. There is also the danger of the workers' being overcome by the fumes of petrol which may be present.

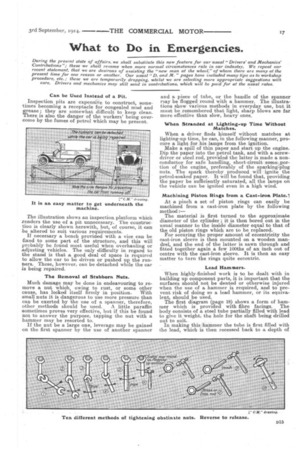

It is an easy matter to get underneath the machine.

The illustration shows an inspection platform which renders the use of a pit unnecessary. The construction is clearly shown herewith, but, of course, it can be altered to suit various requirements. If necessary a bench provided with a vice can be fixed to some part of the structure, and this will probably be found most useful when overhauling or adjusting vehicles. The only difficulty in regard to the stand is that a good deal of space is required to allow the car to be driven or pushed up the runners. These, however, can be detached while the car is being repaired.

The Removal of Stubborn Nuts.

Much damage may be done in endeavouring to remove a nut which owing to rust, or some other cause, has locked itself firmly in position. With small nuts it is dangerous to use more pressure than can be exerted by the use of a spanner, therefore, other methods should be used. A little paraffin sometimes proves very effective, but if this be found not to answer the purpose, tapping the nut with a hammer may be resorted to.

If the nut be a large one, leverage may be gained on the first spanner by the use of another spanner and a piece of tube, or the handle of the spanner may be flogged round with a hammer. The illustrations show various methods in everyday use, but it must be remembered that light, sharp blows are far more effective than slow, heavy ones.

When Stranded at Lighting-up Time Without Matches.

When a driver finds himself without matches at lighting-up time, he can, in the following manner, procure a light for his lamps from the ignition. Make a spill of thin paper and start up the engine. Dip the paper into the petrol tank, and with a screwdriver or steel rod, provided the latter is made a nonconductor for safe handling, short-circuit some portion of the engine, preferably of the sparking-plug nuts. The spark thereby produced will ignite the petrol-soaked paper. It will be found that, providing the paper be sufficiently saturated, all the lamps on the vehicle can be ignited even in a high wind.

Machining Piston Rings from a Cast-iron Plate.1

At a pinch a set of piston rings can easily be machined from a cast-iron plate by the following method:— The material is first turned to the approximate diameter of the cylinder ; it is then bored out in the usual manner to the inside diameter equal to that of the old piston rings which are to be replaced. For securing the proper amount of eccentricity the cast-iron sleeve is then mounted on a wooden mandrel, and the end of the latter is sawn through and fitted together again a few 100ths of an inch out of centre with the cast-iron sleeve. It is then an easy matter to turn the rings quite eccentric.

Lead Hammers.

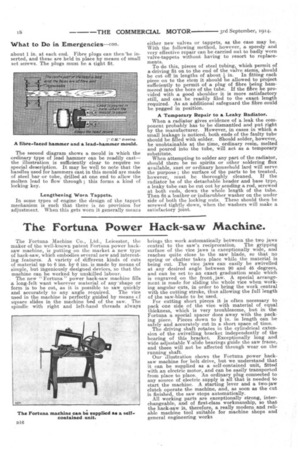

When highly-finished work is to be dealt with in building up component parts, it is important that the surfaces should not be dented or otherwise injured when the use of a hammer is required, and to prevent risk of doing so a lead hammer, or its equivalent, should be used. The first diagram (page 18) shows a form of hammer which is provided with fibre facings. The body consists of a steel tube partially filled with lead to give it weight, the hole for the shaft being drilled out to suit.

In making this hammer the tube is first filled with the lead, which is then recessed back to a depth of about 1 in. at each end. Fibre plugs can therrbe inserted, and these are held in place by means of small set screws. The plugs must be a tight fit.

A fibre-laced hammer and a lead-hammer mould.

The second diagram shows a, mould in which the ordinary type of lead hammer can be readily cast— the illustration is sufficiently clear to require no special description. It may be well to note that the handles used for hammers cast in this mould are made of steel bar or tube, drilled at one end to allow the molten lead to flow through ; this forms a kind of locking key.

Lengthening Worn Tappets.

In some types of engine the design of the tappet mechanism is such that there is no provision for adjustment. When this gets worn it generally means either new valves or tappets, as the case may be. With the following method, however, a speedy and very effective repair can be carried out to badly worn valve-tappets without having to resort to replacements.

To do this, pieces of steel tubing, which permit of a driving fit on to the end of the valve stems, should be cut off in lengths of about in. In fitting each piece on to the stem it should be allowed to project sufficiently to permit of a plug of fibre being hammered into the bore of the tube. If the fibre be provided with a good shoulder it is more satisfactory still, and can be readily filed to the exact length required. As an additional safeguard the fibre could be pegged in position.

A Temporary Repair to a Leaky Radiator.

When a radiator gives evidence of a leak the component probably has to be dismantled and put right by the manufacturer. However, in cases in which a small leakage is noticed, both ends of the faulty tube should be filled with solder. Should solder, however, be unobtainable at the time, ordinary resin, melted and poured into the tube, will act as a temporary substitute.

When attempting to solder any part of the radiator, should there be no spirits or other soldering flux available, suet or ordinary household lard will serve the purpose ; the surface of the parts to be treated, however, must be thoroughly cleaned. If the radiator be of the detachable header and base type, a leaky tube can be cut out by sending a rod, screwed at both ends, down the whole length of the tube. Then fit a leather or indiarubber washer on the under side of both the locking nuts. These should then be screwed tightly down, when the washers will make a satisfactory joint.