KEEN RIVALRY BRINGS TT THE BEST

Page 88

Page 89

Page 90

Page 91

Page 92

Page 97

Page 98

Page 99

Page 100

Page 101

If you've noticed an error in this article please click here to report it so we can fix it.

Hardening Markets Encourage Manufacturers to Adopt New Ideas to Stimulate Sales Air Suspension and Disc Brakes Exhibited for First Time : Larger Engines Prevalent

By John F. Moon, A.M.I.R.T.E.

I. NTENSE competition . between all classes of manufacturer has provided the spur for the remarkable advances in design to be seen at this year's Commercial Motor Show, Markets are hardening both at home and abroad,

and chassis makers are becoming keenly aware of the need to meet operators' requirements and, indeed, to foresee future needs. .

Future trends are 'seen on several chassis which have

been equipped with air .suspension land even disc brakes, whilst more immediate needs are being met by the use

of higher-powered engines, semi-automatic transmissions and specialized chassis layouts which all add up to an emphasis on speed—speed on the road, speed in delivery and speed of maintenance. .

This trend towards specialization can be found on almost every stand at the Show, including those of the mass-producers. For example, the B.M.C. group number among their exhibits the Austin Gipsy -i-ton 4 x 4 vehicle (Stand 61), which has been designed for high-speed cross-country travel, to which end it has a special type of rubber suspension for all wheels.

Vauxhall Motors also show a range of chassis which has been developed to meet needs peculiar to the distributive

trades. Of these the Bedford 4-tonner (Stand 86) is perhaps outstanding because of the use of 16-in.-diameter wheels and

a relatively small power unit. The small wheels give a low-loading height and good cab access, at the same time

making possible a tight steering lock, so that, despite a

normal-control layout, the vehicle is little less manceuvrable than a forward-control model. The small engine can be used because the type of service on which the vehicle will be employed means that the load will be constantly decreasing as drops are made.

Even more specialized is the Dennis Paravan (Stand 94), which was developed with the co-operation of various large parcels carriers. The result is that its chassis layout is tailored to an unorthodox body layout evolved to make the work of a parcels-van driver much simpler.

Another outstanding specialist chassis is the Leyland Atlantean. This design has been produced to cater for the change in the requirements of passenger-vehicle operators. It has a rear engine to give good accessibility and to keep noise, fumes and vibration as far away as possible from the passenger saloon, at the same time making it possible to have an entrance ahead of the front wheels, which can be seen clearly by the driver. Thus the conductor is relieved of some of his responsibility: this is important in double-deckers with a capacity of 70-80 passengers, in which the collection of fares is a full-time job. The Atlantean costs no more than conventional Leyland forward-engined bus chassis.

The growing trend among oilfield companies to demand larger and more powerful tractors and load carriers to handle heavy and bulky pieces of equipment has resulted in there being several ultra-heavy-duty vehicles • at Earls Court. These are the Atkinson' Omega (Stand 99), the Scammell Super Constructor (Stand 83) and the Thornycroft Antar (Stand 98). Engines of more than 200 b.h.p. are available in all these chassis and another feature common to all of them is that a normal-control layout has been adopted.

Not only does this give greater cab space for driver and crew, with a corresponding increase in comfort, but it also gives a far higher degree of engine accessibility than is possible with forward-control vehicles. Consequently, unit replacement and general maintenance are much simpler—an important consideration with vehicles working hundreds of miles from the nearest large depot.

Another new tractor rated at 40 tons gross is the Seddon Sirdar M (Stand 93), powered by a Cummins oil engine. This, too, is a normal-control design.

The backbone of British long-distance haulage continues to be the rigid eight-wheeler, although the use of articulated eight-wheelers is gradually increasing. Eight-wheeler design, which for many years remained static, received, a sudden boost some three years ago when the Thornycroft Trusty PK (Stand 98) was introduced, this having a 130 b.h.p. oil engine, eight-wheel brakes and a roomy cab as standard. Up to that time most British eight-wheelers had engines of 125 b.h.p. or less, and eight-wheel brakes were considered a luxury. This year, however, there are few eight-wheelers' at the Show which do not have brakes at each wheel, and 150 b.h.p. power units are installed in many of them. Concurrently, cab design has been improved beyond all recognition, the present ultimate being that fitted to the Guy heavy-duty vehicles (Stand 62).

The eight-wheeled exhibit which best reflects this general trend is the Foden KE6/24 (Stand 82). This is a lightweight design permitting a payload of about 17+ tons. Low weight has not been achieved by skimping, for the chassis specification includes eight-wheel brakes, the latest version of the Foden six-cylindered two-stroke engine which develops 150 b.h.p., and a 12-in.-deep chassis frame, The Albion Caledonian (Stand 59) is a further lightweight design, having a 125 b.h.p. engine and eight-wheel brakes.

Another lightweight eight-wheeler with a different approach is the Guy Warrior (Stand 62). This is virtually an eight-wheeled version of the Warrior 12-ton-gross fourwheeler with second and fourth axles added to an extended frame. This Warrior chassis has the A.E.C. AV470 112 b.h.p. oil engine, a five-speed synchromesh gearbox, and two-speed axle to compensate for the relatively low engine power. Brakes are provided on six wheels only and the chassis frame has a maximum depth of only 9 in.

So much weight has been saved that a full 18-ton payload can be carried. It makes a sharp contrast to the Guy Invincible eight-wheelers on the same stand, which are available with engines of 150 b.h.p. upwards, eightwheel brakes and 12-in, chassis frames, and are thus more suited to full-time high-speed operation on the motorways which it is promised will soon span Britain. Another new eight-wheeler is the Seddon DD8 (Stand 93), available with engines of up to 168 b.h.p. and having eight-wheel brakes as standard.

This year has seen a spate of new 14-ton-gross fourwheelers, including the Albion Clydesdale (Stand 59), the Leyland Super-Comet (Stand 75), Seddon Mark 15110 with Leyland 110 b.h.p. engine (Stand 93) and the Thornycroft Mastiff (Stand 98).

It has been apparent for some time that many operators have been buying relatively inexpensive 7-tonners and running them, severely overladen, with payloads of up to 10 tons. These four new vehicles are indicative of the desire of the heavy-vehicle manufacturers to try to stop this poaching on their preserves, and they offer high engine power, good braking and robust frames with the object of providing fast and reliable transport, with an overall economy of operation, for payloads of 9-10 tons.

Manufacturers of medium-weight vehicles are still likely to get the lion's share of this market, however, particularly in view of the large number of third-axle conversions bei,pg incorporated on 7-ton chassis to raise the permissible payload to anything up to 12 tons without exceeding legal axle-weight restrictions.

Whereas a few years ago such conversions were not viewed with favour, the position has changed somewhat. • Extra strength is now being built into 7-ton chassis, which makes them more able to cope with payloads above those for which they are officially recommended as four-wheelers.

New 7-tonners coming into this catigory which have been introduced since the 1956 Show are exhibited by Albion (Stand 59), Dodge (Stand 97) and Ford (Stand 92). Commer have entered a new field with the introduction last month of 4-, 5and 6-ton forward-control chassis (Stand 73) powered by Perkins oil engines mounted beneath the cab seats.

Solid progress in the heavier field is evidenced by the A.E.C. group and E.R.F., Ltd. The A.E.C. (Stand 85) and Maudslay (Stand 84) goods-vehicle exhibits show few obvious design changes, but closer inspection reveals that two new oil engines, the AV 590 and 690, are offered in these heavy chassis. These units have a similar design to the smaller AV410 and 470 engines used in passenger vehicles and the Mercury 12-14-tongross chassis, whilst other modifications to frame and suspension have been introduced to further longevity under arduous operating conditions.

Similarly, E.R.F. (Stand 60) have changed the chassis frames of their eight-wheelers to give extra support for tail-end loads and have adopted a new type of lightweight air-braking system. As with other manufacturers, engines of 150 b.h.p. or more are offered. E.R.F. have also joined such concerns as Atkinson, Foden and Scammell in the manufacture of dumpers, the 540 dumper' exhibited being unique in having Girling disc brakes at the front wheels.

Semi-forward-control Six-wheelers

Another important E.R.F. innovation has been the introduction of a range of semi-forward-control six-wheeled chassis. This layout has been adopted primarily with the object of reducing the front-axle loading, so that steering effort is lower and the same size of tyre can be used on front and rear axles. It also has the advantage that less of the engine obtrudes upon cab space, so that seating can be provided for a driver and two mates.

Great as the interest is among medium and heavy exhibits, manufacturers of lighter vehicles have not stood still, and a new entrant into this field is Jensen (Stand 57). They are now manufacturing under licence the German Tempo 25-cwt. range of chassis which, because of their front-wheel drive, have low frames that make them ideally suited to goods-, delivery and passenger bodies.

A further advantage of these chassis is that the engines are set back so that they lie partly beneath the cab seat, thus making for easy access to the driving seat from each side. Independent suspension is used at all wheels, giving good road-holding. These new vehicles should prove as popular in Britain as they have done over the past few years in their native country.

Another new delivery vehicle is the Standard Atlas van (Stand 70), the first true commercial vehicle to be produced by this company, the previous vans having been derived from private cars. The Atlas, like other vans of this type (Austin, Morris and Thames), has the engine set back so that it lies between the cab seats. Thus the driver can reach his seat from the kerbside. Technically, the van is interesting because of its front-end layout.

Front Sub-frame Layout The engine and gearbox are carried on a sub-frame which can be removed reasonably easily from the rest of the vehicle and drawn out on -the front wheels. The independent front suspension also is of interest. A transverse leaf spring is employed, the arrangement being similar to that to be found on some racing cars. The front track is narrow, which improves the steering lock. The Atlas has a smaller engine than is usual in British vans of this capacity, so fuel economy should he good.

Slightly heavier is the new Trojan forward-control 25-cwt. van, the body styling of which is smooth and pleasant. The whicle is powered by the new Perkins Four 99 oil engine and independent front suspension is incorporated, the system consisting of quarter-elliptic springs and trailing links.

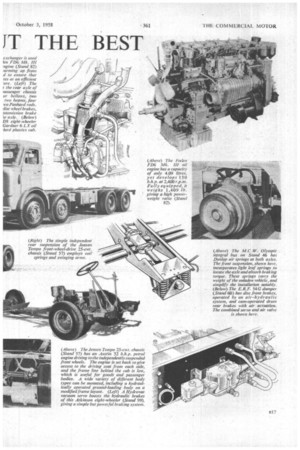

Of the chassis incorporating more advanced designs, the two most interesting are undoubtedly the Guy underfloor-engined passenger chassis (Stand 62) and the Foden FETU6/25 tractor (demonstration park), both of which incorporate air suspension and disc brakes. The Guy passenger chassis has an automatic gearbox also and the complete vehicle weighs 11 cwt. less E20 than its leaf-sprung equivalent—the Victory. Air suspension is featured also on the A.E.C. Reliance and Bridgemaster buses.

There are, however, several other vehicles with air suspension, there being all the signs of a last-minute rush by manufacturers to show experimental prototypes equipped in this way. Most of these are to be found in the demonstration park, including Atkinson, Maudslay and Thomyeroft fourwheelers. Leyland, who have announced that they are offering supplementary air springs for the front suspension of their Atlantean chassis, have developed an air-suspension layout, in conjunction with Dunlop, for the M.C.W. Olympic integral bus (Stand 36).

Growth of Air Suspension

It is encouraging to see so much air suspension at Earls Court this year, particularly in view of the large number of vehicles of this kind shown by German manufacturers at Frankfurt last year. This indicates to prospective overseas customers that anything the Germans can do, Britain can do also.

A surprisingly large number of power units of varying sizes has been introduced since the 1956 Commercial Motor Show.

These range from the Perkins Four 9942.3 b.h.p. four-cylindered unit (Stand 442) to the Gardner 6LX 150 b.h.p. unit (Stand 298). The Perkins engine, in common with another relatively new small unit—the Rover 2-litre 52 b.h.p. engine (Stand 58)— has a C.A.V. distributor-type fuel-injection pump, also used on the Perkins C.305 engine developed for the new Commer forward-control models in six-cylinder form.

Recently introduced engines for 5-ton and 7-ton chassis include the Bedford and Thames six-cylindered units developing 89 b.h.p. (net) and 100 b.h.p. (net) respectively. Smaller than either of these, but developing 150 b.h.p., is the Foden FD6 Mark III engine, which has a specific output of about 37.5 b.h.p. per litre.

The new Gardner engine—the 6LX—is a 10.45-litre model similar in general pattern to the LW series which has been in production for 20 years or more. Although it is no larger externally than the 6LW it has a greater cubic capacity, which has enabled the output to be raised to 150 b.h.p., but the governed speed (1,700 r.p.m.) is no higher. This has proved to be a disappointment to some manufacturers and operators, as it means that to cope with higher road speeds fiveand six-speed gearboxes are essential if an adequate hill-climbing performance is to be obtained. The high torque and low specific fuel consumption of the 6LX are noteworthy.

The Foden engine, however, •has had its governed speed raised to 2,400 r.p.m. and the use of a heat exchanger and thin-wall crankshaft bearings has made it possible to run this engine at consistently high operating temperatures with corresponding improvement in general efficiency. It is specified in the lightweight eight-wheeler with a simple four-speed transmission, whereas the previous eight-wheeler with the 120b.h.p. Mark II engine really needed a 12-speed gearbox to get the best performance out of the unit to meet a variety of operating conditions.

. The use of turbochargers is gradually growing. This is an obvious way to get a higher output from an engine without noticeably increasing its size or weight. Turbocharged engines have " been produced by Thornycroft for several years and Daimler are now offering one of their oil engines with a B.S.A. turbocharger for bus use.

Turbocharging for Power and Economy Many operators also are turning to turbocharging to increase the outputs of standard engines. An example of this trend is seen on the Plaxfonstand (48), where there is an A.E.C. Reliance luxury coach for Sheffield United Tours, equipped with an Eberspacher turbocharger which raises the output of the engine from 125 b.h.p. to 140 b.h.p, at 1,200 r.p.m. The maximum power could obviously be increased still further, but this modest uprating will ensure improved fuel economy, as with the Daimler application.

There are several examples of detail improvements to existing power units and their accessories. One of the most prominent of these is the adoption of paper-element air cleaners by several manufacturers, including one used by Fodens which has awhistle incorporated in the release valve to give audible warning when the filter .heconags clogged. Paper-element filters confer advantages in respect of cornpactness and light weight when compared with the oil-bath type, and they are easier to mount, as it is not necessary to install them vertically to ensure that no oil -can spill out.

Running temperatures have also been receiving consideration and two manufacturers—Foden and Perkins—have adopted waxtype thermoStats in some of their engines. These devices have been shown to be more predictable in their opening temperatures than the bellows type more commonly employed.

Further aids to engine efficiency are to be seen on accessory manufacturers' stands. The Smiths magnetic fan drive is notable (Stand 2510). This ensures that the engine is not losing power to the fan when it is operating at low temperatures, the drive to the fan being made only when an optimum operatingtemperature has been exceeded. Similar results are given by the SerckBehr hydrostatic fan drive, which is to be seen on the B.U.T. stand (88) on an Albion-Leyland 0.900 railcar engine. This is somewhat complicated, however, and would be difficult to install in a road vehicle.

British operators become attached to a certain make of power unit and this often governs their choice of chassis. With this in mind several manufacturers, notably Foden, Guy and Seddon, are now offering a wide variety of makes of engine in some of their chassis. There is also a distinct trend among certain other chassis makers towards using power units made by other vehicle manufacturers, rather than proprietary units, High-powered engines are gaining in popularity at last, and these will be even more necessary to cope with the high speeds allowable on the new motor roads.

Semi-automatic Gearboxes Popular

One of the most noticeable features in transmissions has been the rapid growth in the adoption of semi-automatic gearboxes. It is encouraging to note that the box that has been most widely employed by British chassis manufacturers is based on the British Self-Changing Gears design, although some wellestablished American gearboxes are being made over here.

The use of a semi-automatic gearbox in a passenger vehicle, particularly one engaged on stage-carriage work, is common sense, but it is only recently that such types of transmission have been applied■ to goods vehicles. Atkinson have been among the pioneers in this direction and they are exhibiting an eight-wheeler with a semi-automatic gearbox, in addition to the Omega oilfields tractor which has an eight-speed semiautomatic unit.

This same basic eight-speed gearbox is a feature also' of the Scammell Super Constructor, but whereas in its standard form it has electro-pneumatic actuation, for the Scammell application the chassis makers have developed an all-pneumatic control system. It is not difficult to appreciate what a difference the use of such a gearbox makes to an outfit running at some 150 tons gross train weight, particularly over soft ground and sand.

The fully automatic versions of the Self-Changing Gears gearboxes are also gaining in popularity, primarily in the passenger-vehicle field. Not only do Leyland, A.E.C. and Atkinson offer automatic versions, but both Daimler and Guy haire developed their own fully automatic versions of the boxes that they make under licence and examples of these are to be seen on their respective Stands. So simple to drive are buses with automatic transmissions that my secretary, who had never even been in the cab of a double-decker before, drove a Daintier bus confidently, making expertly smooth gear changes without difficulty.

In view of the relatively rapid progress that has been made with this type of gearbox during the past few years it is not surprising that the change-over from the constant-mesh gearbox formerly in vogue has tended to by-pass synchromesh transmission. Most of the medium-capacity chassis makers, with the exception of B.M.C., are able to offer synchromesh gearboxes. In many cases these are standard fittings, but among the heavier groups of chassis the constant-mesh box still reigns supreme.

Synchromesh transmissions capable of delivering the torque needed for such vehicles would naturally carry -a price penalty, and in many instances gear-changing demands more hard work Of the driver because of the need to overcome the action of the synchromesh cones. In this respect, however, the current David Brown series of synchromesh gearboxes is an exception its action being very light. For really heavy gearboxes Clayton Dewandre offer an air-pressure change system, a commor feature on Continental chassis.

Greater Torque Capacities

The higher power outputs of the larger engines now being offered in heavy chassis have made it necessary for certain gearbox manufacturers to uprate torque capacities. Other manufacturers—for example, David Brown and Moss—are offering 10-speed gearboxes for use in ultra-heavy-duty machines where there is a need for both high speed and good hill-climbing ability.

Among small vans it is common to find synchromesh gearboxes, because such designs normally incorporate private-car components, but there iss-a fully automatic gearbox—the Hobbs Mecha-matic—which has been specially developed for use in light vehicles, the system also being applicable to medium and heavy goods vehicles. This unit has an advantage over certain American types in that transmission efficiency is relatively high and there is little penalty to pay in respect of fuel eosts.

• Changes in rear-axle design are also evident. One of the most noteworthy departures from normal practice has been the adoption of a double-reduction axle on Albion and Leyland 7-ton and 9-ton vehicles, this unit having epicycIic hub-reduction gearing. Another significant move by Leyland Motors is the use of thrust pads to support the worm wheels of their current worm-driven axles.

This relatively simple departure from normal practice has already been shown to lengthen the life of the worm axle so that it approaches that of a spiral bevel unit, but allows much higher torque to be put through. Thus, some of the inherent disadvantages of worm axles are overcome in one fell swoop, and this could well mean a new lease of life for them.

One of the Leyland exhibits—a Buffalo six-wheeled tractor (Stand 103)—has an air-operated lockable third differential. The Kirkstall lockable third differential (Stand 439Q—R) also incorporates air operation. A possible disadvantage of a lockable third differential is that it can be left locked while the vehicle is running on the road and some manufacturers claim that tyre wear is increased unless the third differential is in operation between the two driving axles of a multi-wheeled vehicle.

A few manufacturers, however, hold that a third differential does little to lengthen tyre life and a compromise is to be seen on the Guy Invincible multi-wheelers. The double-drive versions are offered with a ZF limited-slip third differential which allows slight slip on the road so as theoretically to lengthen tyre life, but locks up when any of the four wheels starts to skid, as can occur on ice, snow or mud.

Other rear-axle trends include the adoption of an Allard De Dion-type rear axle (Stand 396M) for use on certain 3.M.C. chassis, this having originally been developed at the request of London County Council for their ambulances. This E26 De Dion layout has the advantage of allowing the body floor line to be kept low, as there is no need to give bump clearance above the fixed differential pot.

Another type of transmission with a fixed differential is found on the. Austin Gipsy, this chassis having independent suspension on all wheels with open drive shafts from the differential to each wheel. The use ' of such .a layout is in direct contrast to that practised on the Land-Rover by the Rover Co., Ltd..(Stand 58), who, for the past 10 years, have. adhered to rigidaxles at front and rear in the interests of Suspension is one of the keynotes of this year's Show, primarily because of the widespread use of air springs, which are to be seen on no fewer than 15 stands (including trailers), with several more vehicles and trailers in the denlonstration park, Over the past two years The Commercial Motor has repeatedlY stressed the advantages to be derived from air. suspension: indeed, in thern 1956 Show -review I commented on the appearance of a Silentbloc-Andro air pillow exhibited among the accessories and said that the progress of this unit would be watched with interest.

The development of this and other types of air suspension has spread rapidly since then, and so far the most widely used system has been a British design—the Dunlop Pneuridewhich owes no allegiance to any American design, either imported or made in this country.

There are many different views on the best use of air suspension, which is made obvious by the wide variety of installations to be seen at Earls Court. Some manufacturers, such as Atkinson and A.E.C., favour the simplest possible layout so as not to discourage potential customers who might otherwise he afraid of added complexity. Other makers, notably Guy, have gone all out to design special chassis and suspension systems to take full advantage of every possible aspect of air suspension, and the independent front suspension of the Guy underfloor-engined passenger chassis is a good example of this determination.

The main difficulty with air suspension is, of course, that, unlike a leaf spring, the air bag can do nothing to locate the axle and absorb driving and braking torque reactions. This means that radius arms and Panhard rods must beemployed unless, as in the case of the Foden tractor, the Leyland-M.C.W. Olympic and the Thornycroft Mastiff, a light leaf spring is employed at the front axle to provide the necessary location

and at the same time support the unladen chassis. .

With the exception of the A.E.C. installations, which are offered on production vehicles, all the air-suspension layouts on powered chassis are of a purely experimental nature. and it will be interesting to see which system becomes the most widely adopted in the course of the next. two years.

Air is not the only suspension medium which is offered in opposition to metallic springs and there are several examples of rubber suspension on show. The Spencer Moulton Flexitor torsional rubber suspension, as used on the Austin. Gipsy, is a satisfactory form for fight vehicles, except that with a trailingarm installation on the front wheels there it a serious change in castor angle which can affect steering.

For heavier vehicles, however, the Hendrickson tubber suspension system manufactured in this country by Eaton Axles, Ltd., offers wide possibilities for rear bogies. It is compact, easy to install and, like a properly laid-out airsuspension system, requires no lubrication, Furthermore, there

is little --variation between the laden and unladen-heights .of Vehicles so equipped.

So far as front suspension is concerned, with the -exception of the Guy 'passenger chassis, the A.E.C. Bridgemaster and the L.T.E. Routemaster, independent front suspension has not been adopted by heavy-vehicle manufacturers. Indeed, Leyland have reverted to a solid beam axle at the front of their Atlantean chassis in preference to the torsion-bar independent suspension exhibited two years ago On the integral version of this vehicle, The pros and cons of independent front, suspension for a heavy vehicle are numerous and at times a peculiar problem has been found with double-deck buses, which have a high centre of gravity and tend to roll snore, thanconventional goods vehicles. This roll can cause fluctuations in the steering characteristics., under extreme conditions, which could' make the vehicles difficult to handle, although such instances would occur only in flat country-in high wind's.

On light vans and pick-ups which have been derived from private cars independent suspension is general, and usually takes the form of coil springs and wishbones, although in the case of the Standard Atlas van a transverse leaf spring ' is employed. This is held centrally at two points, so that when one wheel is raised the centre of the spring tends to go down and the opposite wheel to go up. This system gives a high degree of roll stability, which compensates for the narrow front track adopted to give a good turning circle.

Multi-rate semi-elliptic springs are occasionally employed on goods and passenger vehicles in an endeavour to give smooth suspension under a variety of load conditions, but these can hardly offer the fully progressive characteristics of an air spring. One unusual approach to this subject, however, is the Cary Laminaire suspension (Stand 370H-M), which Consists essentially of a conventional semi-elliptic spring, the

rear end of which slides against a second leaf spring cantileveredfrom the chassis frame. Increasing load causes the springs to act together, thus progressively increasing the effective rate.

The most recent development with regard to braking is the use of disc brakes, which are to be seen on the E.R.F. dumper, the Guy underfloor-engined passenger chassis and the prototype Foden tractor, in addition to having been fitted to two Dyson trailers. Disc brakes have so far not been developed with the object of increasing maximum retardation, but rather to give good anti-fade characteristics and reduce the need for frequent adjustment, with the added advantage that replacement of the friction material is greatly simplified.

With the exception of one of the Dyson applications, disc brakes so far have been built to be used only with a hydraulic system and, because of the high line pressures involved, an air servo is usually incorporated. In the case of the E.R.F. dumper the discs on the front axle are operated through an air-hydraulic system; for the rear axle, which has conventional cam brakes, straight air-pressure application is employed, the two systems being jointly controlled by a combined air servo arid valve unit.

Of more immediate interest than the disc brake developments is the widespread use of eight-wheeled brakes on eight-wheelers and the increasing adoption of full air-pressure systems. On vehicles of up to 14 tons gross, however, it is becoming common to find a Hydrovac servo operating a hydraulic system, the Hydrovac working on the suspended-vacuum principle which gives more rapid actuation of the brakes than the upright vacuum type of servo formerly employed. Doubled-up Hydrovacs can afford braking power at least as great as that given by an air-pressure system and many Atkinson eight-wheelers are sold with tandem Atlas Hydrovacs.

In fact, some Hydrovacs give so much power that sometimes application of the pedal in an emergency stop tends to cause the wheels to lock, with a corresponding increase in the overall stopping distance. One effective method of preventing wheel

locking(and loss of control under slippery conditions) is the Dunlop Maxaret device, hut this has to be used with a constantflow, hydraulic system, • which could,, cause complications in certain vehicles. For petrol-engined vehicles the Dunlop engineers have developed a simple hydraulic pump working off the induction manifold and an effective power valve with built-in safety device to cater for loss of pressure.

An advantage of the Hydrovac vacuum servo, in addition to its improved performance, is that it is easy to install. As an alternative to it, however, the air-pressure version, known as the Airpak, is now being manufactured in this country by Clayton Dewandre. The Airpak has been used for several years on American and Continental vehicles and although it offers the same power as a full air-pressure system, it consumes less air, thus a smaller compressor can be installed.

So far as hand brakes are concerned, the hand-brake lever invariably actuates the rear brake shoes. In the case of the Guy Invincible models operation is quickened and assisted by a small air-pressure servo controlled electrically with operation of the hand-brake lever. There is, however, a trend towards transmission hand brakes, but these must be mounted on the axle to give greater safety as an emergency brake. Discs are sometimes used for this purpose, but cannot be installed behind an underslung-worm axle, because they reduce ground clearance, which is why the Guy disc-braked chassis has a drum transmission brake.

Frames or Chassisiess?

With regard to chassis frames, there seems to be a definite move away from the trend to adopt integral construction. There are fewer examples of such vehicles at Earls Court this year than there were two years ago, except in the case of the light delivery vans. That weight can still be saved on chassis frames is evidenced by Foden's K-type eight-wheeler and even by the extremely light frame on the Guy Warrior eight-wheeler. One of the possible disadvantages of an integrally constructed design—body limitations—is shown by the fact that the latest Leyland Atlantean has a separate chassis frame.

The use of a separate frame on delivery vans is viewed by some people as an advantage because it gives operators a choice of body types, but the B.M.C. 15-cwt. vehicles are integral and many different types of body can be built on the rigid floor structure.

The most striking development in tyres is the growing popularity of the Michelin X, which has been shown to offer distinct advantages in road-holding, fuel economy, braking efficiency and life. The adoption of tubeless tyres has been slow, although they have proved successful in America, particularly in the larger sizes. The Atkinson Omega exhibited is fitted with 21.00-25-in. (20-ply) tubeless tyres but there are few other chassis with tubeless equipment.

A significant development has been the successful construction of high-speed tyres to fit 16-in.-diameter wheels, as used on the new Bedford forward-control vehicles of up to 4-ton capacity. Formerly, small tyres were restricted to relatively low speeds, but these new tyres carry no speed penalties.

MORE than 50 vehicles with years of manufacture dating from 1903 to 1939 were entered for the second rally of the Historic Commercial Vehicle Club held at the A.E.C. works at Southall last Sunday. Spectators were estimated to exceed 2,000.

Lord Brabazon, chairman of Associated Commercial Vehicles, Ltd., emphasized that although the internal-combustion engine . was now mainly accepted, in the early days of commercialvehicle manufacture, steam or electric propulsion had many adherents, and all these tYpes were represented at the rally. Passenger and goods-vehicle entries were equally divided, whilst fire-engines were understandably well represented in view of their comparatively low annual mileages, coupled with a high standard of maintenance. The entry list was completed by tractors, road sweepers and compressors.

The oldest vehicle was the 1903 Taskers "Little Giant" 4 n.h.p.traction engine originally used to assist horse-drawn vehicles up steep hills (latter-day co-ordinators, please note!). It was entered by Mr. A. B. Fuller and driven by 75-year-old Herbert Smallbones, who helped to build these engines.