BODYWORE

Page 82

Page 83

Page 84

Page 85

Page 86

Page 87

If you've noticed an error in this article please click here to report it so we can fix it.

GETS A LIFT

Bodybuilders Meet Demand for Bigger Vehicles to Carry Heavier Loads : Design Related to Current Labour Problems

By

P. A. C. Brockington,

A.M.I.Mech.E. THERE is no alternative to the tipping vehicle, and the new roadbuilding projects have given an impetus to development work on auxiliary, equipment and so on. And at Earls .Court this year the :design of tipping bodies has hecothe • related to progress in plastics construction and runs parallel to improvements in the technique of lifting unit loads mechanically and in the speed of dig,charging materials pneumatically.

Vehicle makers may claim that they are catering for the demand for bigger vehicles to carry heavier loads. Bodybuilders believe that they created this demand by establishing the merits of the maximum-load and optimum-bulk types of body structure.

Experienced lorry drivers, knowing their worth, may justifiably regard the increase in size as a recognition of their economic value and some will point to the greater cab comfort provided as a tribute to their high status in the industry. In the majority of cases body design is closely related to the labour problem.

Six exhibits at the Show may be cited as apposite to these comments. Anthony Hoists demonstrate an entirely new type of compound tipping gear (Stand 41) offering multiple advantages. Holmes of Prestem (Stand 54) display a Homalloy double-skin plastics tipping body. The three-deck Reall van (Stand 77) sets a new standard for the one-man loading of finished goods, and the insulated meat body shown by County Commercial Cars on stand 111 represents a milestone in the development of fully automatic unloading.

A new venture for the Neville company (Stand 49), a demountable cement tanker, is one of many bulk vehicles equipped with a Wellworthy-Ricardo high-capacity blower for rapid discharge of the material pneumatically. The Atkinson plastics-panelled cab (Stand 99) is a notable example of the attention being paid by the majority of makers to cab comfort and improved driving facilities.

Many technically minded visitors to the Show have been scratching their heads' in an attempt to determine the working principles of the Anthony gear. The layout of the mechanism is simple, but its geometry is complex. A single largecapacity ram operates in a substantially horizontal position and indirectly exerts a thrust on a lever system, the layout of which may be compared with that of a conventional stabilizer hinged in the centre and pivoted to the chassis and body underframe.

The most interesting aspect of the design is the way in which a relatively small triangulated lever is separately linked to the rain and the two arms to provide an upward lift when the body is

horizontal and a progressive increase in the rate of lift as the body is raised. Fitted to an Albion Caledonian eightwheeled chassis, the gear is mounted below a 14+-cu.-yd. light-alloy body. Total weight of the body and gear is 12 cwt., and the rated lifting time is 17 sec.

It is claimed that the gear is lighter than conventional types for a given capacity, and tests have shown that the relatively wide spread of the duplicated arms gives a rigid support to the body under adverse operating conditions.

A new Pilot heavy-duty lifting gear (Stand 116) is also of the lever type and incorporates a single horizontal ram. This can lift a fully loaded 12-cu.-yd. dump body to an angle of 72° in 10 sec. and the body can be lowered under power on to multiple rubber cushions in 8 sec. The vehicle is one of the new Atkinson maximum-load six-wheelers.

A tipper highlight of the 1954 Show, the Telehoist Telever gear, has since been widely applied to all types of vehicle Eli

designed for rough site work and is now available with an auxiliary mechanism to provide shock-absorber action when the body is tipped to a maximum angle of around 70° (Stand 53).

A cam on the pivot arm of the lifting frame opens a pilot valve during the final stage and this actuates a restrictor valve in the spill line. A maximum back pressure of 1,000 p.s.i. is created for final cushioning, and the stabilizing action of the system during high-angle tipping obviates the need to reduce tipping speed to avoid shock effects.

End tip shock absorption by mechanical means is exemplified by the Tatra 7-cu.-yd. 6 x 6 dumper exhibited by the Motokov Company on Stand 101. This comprises a lever-and-spring mechanism to which a body-restraining chain is attached.

The lever is pivoted at the front of the chassis and movement of the body beyond the limiting position raises the front end against the tension of dual coil springs, which provide an initial power-return action as well as cushioning the final tipping stage. Twin underbody rams operate at a pressure of 700 p.s.i.

Developed some 12 months ago by the Spenborough Co. (Stand 27), an outrigged stabilizer is now employed for all the concern's front-of-body tipping gears, and the entire range incorporates rams of the pistonless displacement type. Frontof-body rams are located in the normal position, and the thrust is imparted to a bridge member in line with the body top.

E 12

Hinged side arms are attached by pivots to the body underframe so that all the lifting force is applied to the main longitudinals and lateral displacement of the body does not create stresses in the ram equipment. It is claimed that these rams. are far more resistant to distortion by transverse forces than other types of similar capacity, which is of particular advantage in some applications.

A notable example of front-of-body gears shown by Spenborough is the EPT1400 telescopic three-stage 10-12-ton type fitted to a Dodge 7-ton chassis, which lifts a composite body to an angle of 530:

Known as the model 85 MD, a new Westonifront-of-body tipping gear (Stand 25) is of the four-stage..type and has a maximum stroke of 12 ft. 6 in. This gear is exhibited in conjunction with a special 15-cu.-yd. fixed-sided body, of light-alloy construction designed to the specification of a well-known operator.

Hydrostatic drives have the outstanding advantage that the motor can be located in any position without adding to the complexity of the drive mechanism. Two notable applications of hydrostatic power are demonstrated at the Show. One is a tailboard loader exhibited by Bromilow and Edwards on

stand 33; the other is an auxiliary system on the U-frame equipment displayed by Reynolds Boughton on Stand 29.

The motor of the tailboard loader operates on a principle similar to that of the B. and E. hydraulic swash-plate pump and is employed in conjunction with a duplicated sprocket and chain mechanism. The power of the pump is relayed from the left to the right side by means of a universally jointed shaft. The equipment has a capacity of 15 cwt. and is mounted on a Dennis lorry.

Mounted on a Thames Trader 6D chassis, the Reynolds Boughton equipment comprises a swing-back U-frame hydraulically operated by side rams which can be employed for loading any type of equipment or container on to the body platform. A mechanically operated power winch of 15,000 lb. capacity is located behind the cab, and a recovery winch of 6,000 lb. capacity, -mounted at the front, is driven by a hydraulic motor.

In this application the pressure line is fitted with a blow-off• valve, and the system affords a particular operational advantage in that it obviates mechanical damage by "over-winching."

Vehicles of this kind are being increasingly employed in this country for the transport of equipment that is difficult to load on conventional vehicles, and their extensive use in America and Holland for multi-bucket handling on site work and so on is expected to stimulate interest in the possibilities of such applications in this country.

Plastics construction has now been

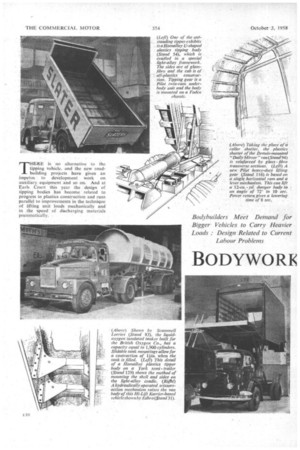

accepted by the majority of bodybuilders as an established trend., but in some cases it is considered that the use of glass-fibre should be limited to lightly stressed members. This material Thwas first employed three years ago as a lining for tipper bodies, and it is therefore of particular interest that the first example of plastics being employed for the main container is to be found at Earls Court this year.

. The Holmes plastics tipper body is of U-shaped section and is mounted on a cradle of Homalloy light-alloy extruded sections. The operators, Slaters Traniport, Ltd., are confident that it will with' stand repeated impact stresses, as well as

the abrasive action of loose load that may be carried. A Pilot twin-ram underbody gear is employed, and the body is mounted on a Foden chassis having a Homalloy full-fronted plastics cab.

A basically similar Homalloy plastics tipping body of 12-cu.-yd. capacity is exhibited by the York Trailer Co. on Stand 129. It is fitted to a 14-ton semitrailer, the lifting gear being a Pilot fourstage twin hoist which gives a tipping

,angle of Hr." This early application of anew type of -tipper body to a semi-trailer is claimed by the makers to be indicative a an important trend.

. If wheel grip is impaired by a loose or slippery snrfaCe the manreuvrabilitY . of the articulated vehicle May: afford iMproved traction for starting from rest because tbe tractor can initially be moved fOrward-at an angle to the axis Of the semi-trailer. Under sorne . condition's the ability Of the driver easily to locate the se-I'M-trailer in an exact tipping. position

has obvious advantages. .

• Erly in the field of all-plastics eon • striiction (without regrets), the Reliant company (Stand 66) exhibit a new pick up based On a standard three-wheeled 5-cwt. chaisis, Which should, have n partiCular appeal to ironmongers and hardyvate MerehantS. Special' tribute, is due to the concern for exploiting plastics construction to expand export markets. The Haifa distributors of Reliant Vehicles have welcomed the use of plastics Materials because it enables them to build special bodies to meet local and re-export requirements without heavy capital expenditure on production equipment.

On a nearby stand (23) the Locomotors plastics-panelled dry-cleaner's body is of a kind which has been employed by the Sketchley company for nearly 12 months and has withstood hard usage in an exemplary way. Seven of these bodies are in regular service and, the Show exhibit is one of a follow-op order for eight vehicles.

The decision to use plastics panelling was originally made because of the better dust-proofing that the material provided and to facilitate the removal of scratches, a small weight reduction being regarded as an attendant advantage. According to the users, the average mechanic cad be easily trained to polish out scratches and to make minor repairs.

Interior panels are of imported Hornitex plastics material and all the panels are colour-impregnated. Rubber gaskets are fitted to both side doors and to the rear door as an aid to dust exclu

sion, and a rear compartment (in which crates of soiled clothes are carried) serves the same purpose..

Strength for the heavy hanging load is provided by deep-section light-alloy transverse members which are supported by an aluminium framework based on top-hat sections. The plastics translucent roof is of particular benefit when a drop is being made at night near street lamps, because of the interior illumination it affords.

Special I-section rails give firm support to hangers and facilitate the removal Or a number of hangers together by a combined lifting and sideways movement. The body is mounted on a B.M.C. 3-ton chassis with a Baico extension of 4 ft. 6 in. and is equipped with a luxurious all-plastics cab and glass-fibre front wings.

The question as to whether glass-fibre can be successfully employed for stressed structural members is answered in the negative by Atkinson's technicians. The concern's new de luxe plastics-panelled cab is the outcome of a policy favouring the use of a wooden framework with metal stiffeners to simport the plastics panels.

Plastics mouldings are, however, employed for the roof ribs, and the

strength of the structure is undoubtedly -enhanced by the resistance to distortion inherent in they Curved front panels and the combined valanee and wing sections.

Faith in all-plastics construction is shown by a number of exhibitors, including Foden (Stand 82), Bowyer Brothers (Stand 128.), Guy Motors' (Stand 62) and Thornycroft (Stand 98). The curvaceous front of the Foden .cab, which is fitted to a HGTU6/25 tractor, is a noteworthy example of adding strength by advanced styling. All these cabs, and many others at the Show, indicate a high regard for driver comfort.

A detail of interest that may show the value of glass-fibre in a new tight is the up-and-over rear door of The Daily .Mirror van shown by Dennis (Stand 94) on a Dennis Fleet Special chassis. This comprises a sheet of material to which angle-section plastics, cross-stiffeners are bonded, and it operates in guides to give the advantages of . a roller 'shutter. The 'makers are confident that 'repeated bending will not result in premature .hardening. or cracking.

The casefor plastics 'construction is also strengthened by the Dennis Paravan production model, which is equipped with glass-fibre panels in place of the lightalloy panels fitted to the prototypes.

Details of this vehicle are being examined speculatively by the users of light delivery vans and by other makers of the type • with particular attention to the up-and-over across-the-corner door on the near side and the low step height. Also based on a 'Dennis chassis, the Sparshatt laundry vehicle (Stand 81) is equipped with a two-piece up-and-over door on both sides, which is hinged below the window section and counterbalanced by a helical spring. The makers emphasize that the doors have a "normal look" from the outside.

At the 1956 Show one of the most outstanding trends indicated by the exhibits was the development of multipurpose bulk vehicles, This year the trend is perpetuated in a different way by the display of two demountable bulkcement tankers and a detachable bulk grain body, and in the same direction by more advanced types of specialized bulkpowder equipment and general-purpose liquid tankers.

A feature of the Neville bulk-cement carrier is the mounting of the mild-steel tank on an open flat-platform light-alloy body, which is based on a Bedford 7-ton chassis and is elevated by Edbro twin-ram front-of-body gear. The rated pressure of the container is 10 p.s.i.

Special truncated pyramidal sockets are employed by Bonallack (Stand 26) for anchoring the Ketton light-alloy bulkcement tank to a standard type of 8-cu.yd. fixed-sided tipping body mounted on a Dodge 7-ton chassis. The WellworthyRicardo blower is equipped with Vokes dry-type air filters and provides a working pressure of 10-12 psi. Twin air agitators are fitted at the rear to obviate bridging of the material across the discharge orifice.

The body is lifted through an angle of 50° by Telehoist LKL Telelever gear. A ridge pole is fitted to the front of the body to facilitate the use of a sheet when the vehicle is employed for carrying sacked loads and so on.

Evolved by Bawn to obviate the use of high-cost specialized bulk vehicles, a semi-trailer-mounted detachable bulkgrain carrier (Stand 133) has three cornpartments and is constructed with a • hopper base to cater for " angle-ofrepose " requirements. The total capacity

of the body is 19 cu. yd. and the grain is discharged through manually controlled slides.

One of the most interesting features of the display is a long auger unit, driven by a small petrol engine, which can be employed for loading the grain from ground level. The semi-trailer is a Tasker 20-ft. model with Scammell coupling.

Claims made for the Carmichael prototype bulk-powder carrier exhibited at the 1956 Show have been substantiated ,by its widespread use for many applications over the past two years. The latest version of the carrier is exhibited by the concern on Stand 122 and incorporates a number of progressive features.

For example, the Wellworthy-Ricardo blower is driven at about three times engine speed by means of a step-up belt drive, combined with a speed-increasing auxiliary gear mounted on the front of the blower. A third air agitator is employed at the front of the container, in addition to two agitators at the rear, to dislodge sticky materials, and manually controlled valves enable the air-topowder ratio to be adjusted to match the heightof discharge by reference to a pressure gauge, which shows an abnormally high reading if the ratio is too low.

The 9-ton tank is lifted by an Edbro twin-ram front-of-body gear and it is mounted on a Leyland Super-Comet chassis. • Evolved for carrying a wide variety of oils, including petroleum spirit, fuel oil, jet fuels and so on, the Darham multipurpose five-compartment tanker (Stand 130) is of 4,000-gal. capacity and is equipped with oval discharge pipes equivalent •to round pipes having a diameter of 5 in., which provide a saving in height of about in. Gunmetal faucets of 2+-in, diameter are available for the gravity discharge of petroleum spirit, and the manifold is arranged so that a Stothert and Pitt pump can be employed for the discharge of other liquids. The chassis is an A.E.C. Mammoth Major.

Providing a different emphasis on the importance of controlled lifting, an insulated meat body displayed by County Commercial Cars on Stand 111 is apparently conventional, but has .detailed features which enable carcases to be unloaded from the roof rails of the vehicle to the rails of the cold store without manual handling.

A Market Loader is used for multiple collections in the normal way, and during transfer of the load it is held in the vertical position; the receiving cups of the loader are mounted on sleeves which are moved sideways to permit the loading hooks to pass the cross-bar on to the store rail system. The body is mounted on a Thames Trader County 6 x 2 conversion (described on page 390). Body height is exactly matched to unloading and reverse-loading requirements.

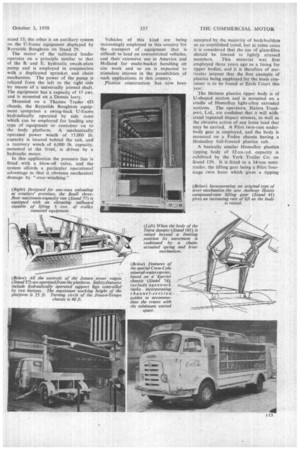

A tailboard gear capable of lifting 5 cwt. of trolley-mounted equipment to the full height of the vehicle is a feature of the maximum-capacity three-floor van shown by Beall (Stand 77). The body is based on a Dyson articulated lowloading semi-trailer chassis and is one of six being supplied to Hoover's to facilitate one-man unloading when deliveries are made to retailers.

Constructed of light alloy, the sections of the upper floors can be readily removed to aid internal movements. Wood-filled steel sections are employed for the main framing to give adequate vertical and transverse support for the heavy side loads.