Weight Reduction Outstanding in Goods Bodies

Page 69

Page 70

Page 71

Page 72

Page 73

If you've noticed an error in this article please click here to report it so we can fix it.

By P. A. C. Brockington, A.M.I.Mech.E.

MANY of the goods bodywork exhibits at the Commercial Motor Show this year indicate that the two contrasting trends of adaptability and specialization in design can be compatible. Whilst the importance attached to the loadcarrying capabilities of tippers and to detailed improvements in their design . represent the first interest of a majority group of users, developments in dualpurpose and multi-purpose vehicles are, in many instances, more original in concept.

Constructional features of the standard type of van, the layout of mobile shops, the design of bodies for a specific use and the attention paid to suitability are indicative of a tendency which is basic to progress— that of obtaining the optimum benefit from the mechanical capabilities of the chassis..

Overshadowing all other developments and trends, and complementary '.o a large number of them, is weight reduction. Whilst this is, in the main, a function of light-alloy construction, the economic use of steel and wood also plays a part which must be given full credit.

Before the war, it could be assumed that the platform lorry was the least amenable of all vehicles to progressive bodywork changes. Two of the exhibits shown by BonaHack and Sons, Ltd., on Stand 92 are symptomatic of the attention which is now paid to this basic type, an entirely new vehicle, shown for the first time, being a platform lorry based on a Leyland Comet 8-ton chassis. This has Dekaloy heavy-duty flooring laid transversely to raise its load capacity without increasing weight.

To emphasize the general-purpose properties of the body, it is shown with a light-alloy bulk-grain container, strapped in position, which discharges through two hoppers at the sides. Grain transport is essentially seasonal, and when the vehicle is not required for this work the container can be removed.

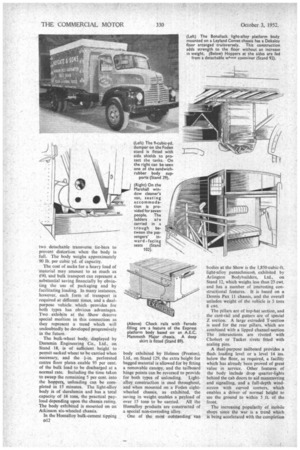

The tipper operator is probably the most critical of all vehicle users, and he values rigidity and correct load distribution as the most important characteristics. The 23.1-cubic-yd. tipper, exhibited by Pilot Works, Ltd., on Stand 103, is of outstanding interest, as the body combines these features with lightweight construction, which provides a saving of 14 cwt. compared with the wood-and-steel body previously fitted. The vehicle is one of a number which has run over 66,000 trouble-free miles for the National Coal Board.

The tipper is based on an A.E.C. Mammoth Major eight-wheeled chassis, fitted with a Pilot U7 twin-ram lifting gear with a thrust capacity up to 18 tons. The body is built on 9-in. by 3i-in. aluminium-alloy longitudinal runners and 14 alloy channel-section cross-bearers with a depth of 4 ins. The sides, floor and loading board are of square corrugated-section extruded alloy.

An important feature of the body which contributes to rigidity is the wide span of the stabilizer. This is pivoted at the sides on outrigger brackets in front of the tipping-gear assembly and attached to the chassis by large plates to spread the load. The height of the tailgate is reduced to allow a fixed bracing panel to be fitted above it, which is used in conjunction with four diagonal braces of angle section and

two detachable transverse tie-bars to prevent distortion when the body is full. The body weighs approximately 90 lb. per cubic yd. of capacity.

The cost of sacks for a heavy load of material may amount to as much as DO, and bulk transport can represent a substantial saving financially by obviating the use of packaging and by facilitating loading. In many instances, however, each form of transport is required at different times, and a dualpurpose vehicle which provides for both types has obvious advantages. Two exhibits at the Show deserve special mention in this connection as they represent a trend which will undoubtedly be developed progressively in the future.

The bulk-wheat body, displayed by Duramin Engineering Co., Ltd., on Stand 18, is of sufficient height to permit sacked wheat to be carried when necessary, and the fin, perforated centre floor plates enable 95 per cent. of the bulk load to be discharged at a normal rate. Including the time taken to sweep the remaining 5 per cent, into the hoppers, unloading can be completed in 15 minutes. The light-alloy body is of duralumin and has a total capacity of 18 tons, the practical payload depending upon the chassis rating. The body exhibited is mounted on an Atkinson six-wheeled chassis.

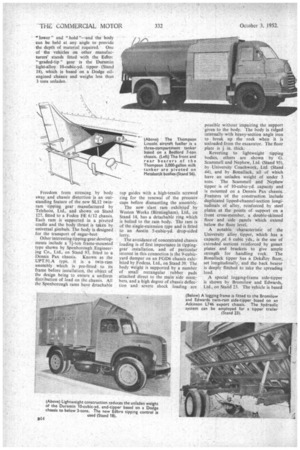

In the Homalloy bulk-cement tipping body exhibited by Holmes (Preston), Ltd., on Stand 129, the extra height for bagged material is allowed for by fitting a removable canopy, and the tailboard hinge points can be reversed to provide for both types of unloading. Lightalloy construction is used throughout, and when mounted on a Foden eightwheeled chassis, as exhibited, the saving in weight enables a payload of over 15 tons to be carried. All the Homalloy products are constructed of a special non-corroding alloy.

One of the most outstanding van bodies at the Show is the 1,850-cubic-ft. light-alloy pantechnicon, exhibited by Arlington Bodybuilders, Ltd., on Stand 12, which weighs less than 25 cwt. and has a number of interesting constructional features. It is based on a Dennis Pax 11 chassis, and the overall unladen weight of the vehicle is 3 tons 8 cwt.

The pillars are of top-hat section, and the cant-rail and gutters are of special Z section. A large extruded T-section is used for the rear pillars, which arc combined with a lipped channel-section The intersections are riveted with Chobert or Tucker rivets fitted with sealing pins.

A dual-purpose tailboard provides a flush loading level or a level 14 ins. below the floor, as required, a facility which has already been proved of great value in service. Other features of the body include drop quarter-lights behind the cab doors to aid manceuvring and signalling, and a full-depth windscreen with curved corners, which enables a driver of normal height to see the ground to within 5 ft. of the front.

The increasing popularity of mobile shops since the war is a trend which is being accelerated with the completion

• of so many new housing estates, and as a class these vehicles represent an important development in the solution of travelling difficulties associated with new residential areas. All the mobile shops exhibited make the most use of the available space in a decorative manner, a notable example being the new flower shop displayed by J. H. Jennings and Son, Ltd., on Stand 17. This is based on an Austin 2-ton longwheelbase chassis with a 2-ft. 1-in. wheelbase -extension and has an overall length of 21 ft.

The interior is separate from the cab and is divided into two compartments, one of which is located forward of the customers' entrance to provide a stock room having cupboards and washing facilities. The main compartment is fitted with curved display stands on one side for vases and hanging baskets and display cabinets on the other for seeds, bulbs and so on. All the framing is constructed of hardwood, plated where necessary, and the panels are of aluminium.

These observations indicate some of the varied types of bodywork development which can be seen at Earls Court, and show that, from the platform lorry to the mobile shop, the bodybuilder has developed an objective awareness of customers' requirements. There is also gratifying evidence that the bodybuilder and chassis manufacturer are becoming increasingly alive to each other's problems.

Reverting to platform lorries, a particularly interesting brewer's body on a 4/4 D.V.E. chassis is shown by Sentinel (Shrewsbury), Ltd., on Stand 54. The body was designed to reduce the loading height by 6 ins, and provide the maximum floor area. The floor bearers are attached direct to the frame by means of mountings with a bolted U fitting, which obviates rusting of the frame member under the wooden bearer and facilitates removal.

Detailed features of the flat body shown by Express Motor and Body Works, Ltd., on Stand 89 (mounted on an A.E.C. Mammoth Major chassis) are a Ferodo-filled chock rail of light alloy, and a deep skirt having recesses for the rope handles.

Included in the exhibits of Carmichael and Sons (Worcester), Ltd. (Stand 4) is a cattle-truck container body, mounted on a Thornycroft Sturdy Star chassis, which can be removed when the vehicle is required as a platform or drop-sided vehicle. If

required, equipment can be supplied for converting the truck container into a horsebox.

Stake-sided general-purpose platform lorries are used in large numbers in America, and the display of a vehicle of this type, with hinged and detachable sides, on Stand 16, by Anthony Hoists, Ltd., may indicate a new trend in this country. Of even greater interest is the use of Sigma ribbing under the swaged floor, which was introduced to obviate dimpling and later proved that it possessed the additional advantage of weight saving. The body is mounted on a Morris-Commercial NVS 13/5 chassis and is fitted with the Anthony hydraulic tailboard loader.

Controlling the discharge rate to obtain even spreading of the material as the vehicle is driven forward is a valuable characteristic in tippers for many kinds of service, and the need for such a control has been supplied by Edwards Bros. (Tippers), Ltd., by the introduction of the 2 TWN tipping gear, which incorporates a manually operated valve. It is shown on Stand 21, fitted to a 7-ton three-way tipper body which is mounted on an Albion chassis.

A short control lever in the driver's cab has three positions—" tip," lower" and "hold "—and the body can be held at any angle to provide the depth of material required. One of • the vehicles on other manufacturers' stands fitted with the Edbrc " graded-tip " gear is the Duramin light-alloy 113-cubic-yd. tipper (Stand 18), which is based on a Dodge oilengined chassis and weighs less than 3 tons unladen.

Freedom from stressing by body sway and chassis distortion is an outstanding feature of the new SL12 twinram tipping gear manufactured by Telehoist, Ltd., and shown on Stand 127, fitted to a Foden FE 6/12 chassis. Each ram is supported in a pivoted cradle and the body thrust is taken by universal gimbals. The body is designed for the transport of sugar-beet Other interesting tipping-gear developments include a 71-ton frame-mounted type shown by Spenborough Engineering Co., Ltd., on Stand 93, fitted to a Dennis Pax chassis. Known as the UPT.91.A type, it is a twin-ram assembly which is pre-fitted to its frame before installation, the object of the design being to ensure a uniform distribution of load on the chassis. All thc Spenborough rams have detachable top guides with a high-tensile screwed ring for the renewal of the pressure cups before dismantling the assembly.

The new slant ram exhibited by Weston Works (Birmingham), Ltd., on Stand 14, has a detachable ring which is bolted to the ram body. The ram is of the single-extension type and is fitted to an Austin 5-cubic-yd. drop-sided lorry.

The avoidance of concentrated chassis loading is of first importance in tippinggear installation, and of particular interest in this connection is the 9-cubicyard dumper on an FGD6 chassis exhibited by Fodens. Ltd., on Stand 39. The body weight is supported by a number of small rectangular rubber pads attached direct to the main side members, and a high degree of chassis deflection and severe shock loading are possible without impairing the support • given to the body. The body is ridged internally with heavy-section angle iron to break up the rock when it is unloaded from the excavator. The floor plate is in. thick.

Reverting to lightweight tipping bodies, others are shown by G. Scammell and Nephew, Ltd. (Stand 95), by University Coachwork, Ltd. (Stand 44), and by Bonallack, all of which have an unladen weight of under 3 tons. The Scammell and Nephew tipper is of 10-cubic-yd. capacity and is mounted on a Dennis Pax chassis. Features of the construction include duplicated lipped-channel-section longitudinals of alloy, reinforced by steel plates at the points of support on a front cross-member, a double-skinned floor and side panels which extend below the floor level.

A notable characteristic of the University alloy tipper, which has a capacity of 6 cubic yds., is the use of extruded sections reinforced by gusset plates and brackets to give ample strength for handling rock. The Bonallack tipper has a Dekiloy floor, set longitudinally, and the back bearer is deeply flitched to take the spreading load.

.A special logging-frame side-tipper is shown by Bromilow and Edwards, Ltd., on Stand 23. The vehicle is based

on an Atkinson L746 chassis and has a tipping-gear control system providing for operation of a tipping trailer. A universal feature of the concern's end tippers intended for export is the use of a detachable cab canopy; this is stored in the_body to save space when the vehicle is prepared for shipping.

A twin-ram gear, known as the SL12, with a capacity up to 20 tons, has recently been added to the range of equipment produced by Anthony Hoists, Ltd., and an example of the gear is shown on Stand 16, fitted to a heavy steel tipper of 10-cubic-yd, capacity, mounted on a Thornyeroft Trusty chassis. The floor of the body is laminated with two steel plates and a 11-in. wood filler to withstand the shock of rock loading.

The 5-cubic-yd. steelbodied end tipper, exhibtied by the Eagle Engineering Co„ Ltd., on Stand 35, has two orig

inal features. The tailboard is fitted with a device which automatic

all turns back the locking clamps as the body is tipped and returns the damps to relock the tailboard when the body is lowered. Also new is a V-shaped body front which reduces the waste space between the cab and body and provides extra loading capacity.

One of the main problems confronting the tanker designer is to provide the container with adequate support for its whole length and at the same time to avoid the transmission of deflection stresses from the vehicle chassis to the barrel structure. Two tanker manufacturers, exhibiting at the Show, employ rubber-bushed mountings to overcome this difficulty, but the two designs are basically dissimilar in concept.

The 3,000-gallon stainless-steel milk tank, mounted on a Leyland Octopus chassis, which is exhibited by Thompson (Bilston), Ltd., on Stand 56, has two Metalastik bushes as pivot mountings for the end bearers. The intermediate bearers are mounted on sandwich rubber pads, and the varying degree of flexibility provided by this layout conforms to the chassis deflection characteristics, thus the container can be designed as a separate unit.

The 3,600-gallon stainless-steel tank on an A.E.C. Mammoth chassis and the 2,000-gallon tank based on a Leyland Comet chassis, which are shown by the A.P.V. Co., Ltd., on Stand 32, both have four bearers supported by two Silentbloc bushes. The chassis is reinforced by uprights between the flanges of the main members at various points, and flexing is controlled or absorbed by relating the bush characteristics to the load to protect the tank against road shocks arid chassis distortion. The bearers, straps and brackets are of light alloy.

Constructional developments in van bodybuilding are often unobtrusive in character and easily overlooked. For example, the body side panels of the furniture body, exhibited by Marshalls Motor Bodies, Ltd., on Stand 102, are of Flexometal, secured to the hardwood framing by Aerolite glue, a feature which cannot be checked by visual • inspection. Special aluminium foil flashing is employed to exclude moisture from the panel edges.

A 1,450-cubic-ft. " bulk " body, displayed by Kingsland and Sons (Camberwell), Ltd., on Stand 13, is based on a Guy Vixen chassis, and the total unladen weight of the vehicle is under 3 tons. Hardwood framing, reinforced with concealed steel plate, is combined with aluminium-alloy channel-section cross-bearers and Huntalloy floor covering, and the body is panelled with Iflyrnax.

Of unusual interest on the stand (57) of Spurting Motor Bodies, Ltd., is the use of anti-vibration mountings for the Spurrnomet all-metal van body, based on a Bedford 30-cwt. chassis. The body is constructed of six basic sheet-metal sections, comprising the roof, ficior, sides, partition and rear door, which are all welded and spot riveted throughout.