MAKING BEST USE OF THE FORD.

Page 47

If you've noticed an error in this article please click here to report it so we can fix it.

Valuable Advice on Every Phase of Ford Transport, Which will Appeal to the Owner, Driver and Repairer.

TN THIS series of hints conCern ing the Ford light chassis and ton truck, we endeavour to deal 'with. the subject from every viewpoint, so ' that the advice will appeal to the owner, driver, maintenance engineer or mechanic.

We shall welcome for inclusion among the hints those which have proved of value to individual users, • and will make suitable remuneration for any which are published.

356.—Overcoming a Contact • Assembly Trouble.

While reading an account of a failure in a Ford magneto which appeared in one of our recent issues, a reader was reminded of one caused by the overheating of a patent New King contact assembly on another magneto. The fault was shown by constant misfiring and bad pulling, and it righted itself so soon as the engine was switched over to the battery. When tested by a voltmeter connected , between the .contact terminal and a clean part of the transmission case. the reading fluctuated between 0 and 6 volts,. the teat being made with the engine running on the battery and the magneto wire removed.

The second test was made by removing the contact assembly and placing the vrdtmeter win in contact with a blob of solder on the periphery of the coil asSemblY, a finger being inserted into the hole. to keep the wire in contact.

The engine was started and the voltmefei gave a reading of 13, thus proving the fault to be in the Contact assembly. Therefore, if stranded through the failure of a flywheel magneto equipped with an aasembly of this type a driver would be able to get his vehicle home by removing the plate through which pass the three screws, the trouble being caused by an intermittent short circuit through the cracked composition, the crack having become conductive through the 'adhesion of the carbon and dirt, thus shorting the current from the centre to the plate and thence to the transmission case. By removing the plate and screwing the contact assembly back into position without it, a short circuit is itn

possible and the vehicle will carry on until a new assembly can be fitted.

357.—Replacing the Cylinder Head.

The two setscrews at the back of the cylinder head block have to be in& rted in their holes before replacing the head, as there is insufficient clearance between the dash and the head to put them into position once the head is in place.

The difficulty is that unless the setscrews are supported in some manner they drop right through up to the hexagon head and cause the cylinder, head to jam while it is being put into place.

This trouble can be avoided by the simple device of holding theta in place with a rubber band, such as that from a pickle jar.

358.—Preventing Front-wheel Wobble.

Wobbling or shimmying of the front wheels is often caused by a loose or worn front radius rod, which allows the front axle to lose its set, i.e., the axle end becomes practically vertical, whereas the stub-axle pins should be set back at the top. This state of affairs is often caused by wear on the ball joint at the rear, although sometimes it is the result of bending of the radius rods, in which case the axle can often be set to the proper amount by use of a long steel bar with a forked end bent up at right angles.

If, however, the fault be due to wear, a copper shim can be fitted between the halves of the ball housing. The copper should be well annealed, the piece required being about 2 ins, square and of a thickness depending upon the amount of wear. This should be placed over the ball housing of an old crankcase and a radius-rod bah hammered down against the copper to bring the shim into the proper shape ; afterwards a portion of the shim, about I in. long, should be bent over to register with the neck of the ball on the rod. This keeps the shim from moving out of position.

A: the housing and its cover usually wear to a larger radius than that of the ball it is advisable to thin off the upper part of the shim by means of a file so that the sides are thicker than the top. Similar shims can also be made for the steering-rod ball joints, anil will ba found effective in taking up wear.

359.—The Care of the Clutch.

In adjusting the clutch, care should be taken that all the finger pins bear the same amount of pressure, or the tendency will be to throw the driving plate sideways, causing excessive wear on the bush, and, eventually, clutch slip. If wear has taken place in the plates so that the finger pins go right down, an extra plate should be inserted, and this should be a large one, as a small one would be liable to drop over the back of the inner clutch drum and it would not then be possible to get top gear.

A properly adjusted spring should measure from 2 ins. to 2* ins, from edge to edge. The measurement should be taken while building up the transmission after the clutch spring pin has been inserted.

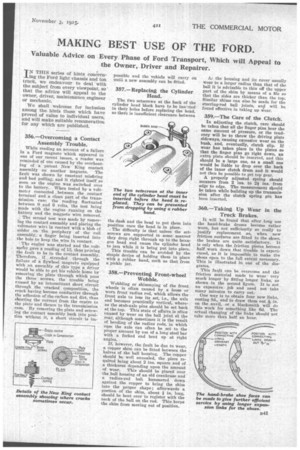

360.—Taking Up Wear in the Truck Brakes.

It will be found that after long use the hand-brake drums become rather worn, but not sufficiently so really to justify replacement as, when new friction surfaces are fitted to the shoes, the brakes are quite satisfactory. It is only when the friction pieces_ become half, .worn down that trouble is experienced, as it is impossible to make the shoes open to the full extent necessary. This is illustrated in one of the diagrams.

This fault can be overcome and the friction material made to wear very much longer by fitting longer links, as shown in the second figure. It is not an expensive job and need not take many minutes to carry out.

One way is to obtain four new links, costing 8d., and to draw them out -PK in. on the anvil, or a blacksmith will do this work for something like 6d. The actual changing of the links should not take more than half an hour.