A WHEEL FOR ABSORBING ROAD SHOCKS.

Page 12

If you've noticed an error in this article please click here to report it so we can fix it.

A French Product with a Fibre Centre and an Unusual Type of Spring.

A SHOCK-ABSORBING wheel for t X. all types of industrial motor vehicle was brought out in France some 4i years ago ander the name of the J.F.C. This wheel was first exhibited at the Paris Salon of 1922. It

has since made quiet, but steady, progress, and the present types of J.P.C. wheel in use are greatly improved and very much lighter than the original models.

A special feature of the J.F.C. is the fact that, embodying in itself a complete suspension system, independent for each wheel, it eliminates much unsprung weight from the chassis.

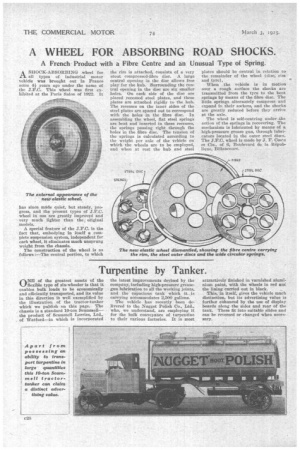

The construction of the wheel is as follows :—The central portion, to which the rim is attached, consists of a very stout compressed-fibre disc. A large central opening in the disc allows free play for the hub. Surrounding the central opening in the disc are six smaller holes. On each side of the disc are placed _recessed steel plates, and these plates are attached rigidly to the hub. The recesses on the inner sides of the steel plates are spaced out to correspond with the holes in the fibre disc. In assembling the wheel, flat steel springs are bent and inserted in these recesses, the springs passing right through the holes in the fibre disc. The tension of the springs is ealculated according to the weight per axle of the vehicle on which the wheels are to be employed, and when at rest the hub and steel plates should be central in relation to the remainder of the wheel (disc, rim and tyre).

When the vehicle is in motion over a rough surface the shocks ate transmitted from the tyre to the bent springs by means of the fibre disc. The little springs alternately compress and expand in their sockets, and the shocks are greatly reduced before they arrive at the axle.

The wheel is self-centring under-the action of the springs in recovering. The mechanism is lubricated by means of a high-pressure grease gun, through lubricators located in the outer steel discs. The .T.F.C. wheel is made by J. F. Cost° at Cia.. of 6. Boidevard de. la ItCmublique, Bilioncourt.