No. Drivers &Mechanics

Page 19

If you've noticed an error in this article please click here to report it so we can fix it.

TEN SHILLINGS WEEKLY is paid for the best communication received, and one penny a line of ten words for anything else published, with an allowance for photographs.

Light Up Your Lamps At — 9.6 on Thursday ; 9.8 on Friday ; 9.9 on Saturday ; 9.10 on Monday ; 9.11 on Tuesday; 9.12 on Wednesday.

A _Cheap Trailer-guard. .

The sender of the blowing communication has been awarded the Ws. prize this veek.

[1633] " A.H.1.47." (Bristol) writes :—"l enclose a sketch [which we have had redrawn.—EDJof a trailer guard, which I made myself some time ago, and which has given complete satisfaction. Its principal advantages are its simplicity and Tow cost. The materials; which comprise two small pulleys and a wire rope, the latter may be one such as is generally used as a clothes line; can be purchased for two shillings.

" The pulleys are fastened to the back of the tractor, as shown in the sketch, the wire is booked to one of the fore-corners of the trailer body (not the chassis of the trailer), passed over the pulley, on the same side, across the back of the wagon, round the second _pulley, and back to the other corner of the trailer. Other pieces of the wire rope are suspended from this, and connected to it by loops, as the sketch shows. The short horizontal stretches on the lower wires are better if carried in pieces of piping. In attaching this second wire, the ends should be fixed at not less than 18 ins, from the pulleys, so as to allow for the necessary movement of the guard when rounding corners.

" I hope I have made myself quite clear, and if not, should be pleased to show the guard to anyone interested who happens to be in my district (Clifton, Bristol). I might point out that another advantage of this contrivance, in addition to those already named, is that it can readily be attaehed or. detached."

When Testing Pistons.

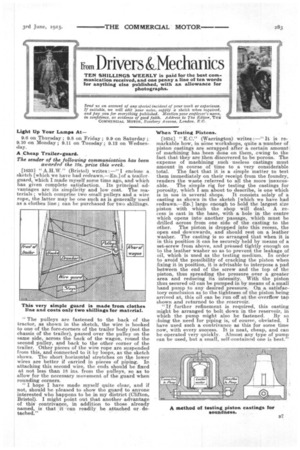

[1634] "E.G." (Warrington) writes :—" It is remarkable how, in some workshops, quite a number of piston castings are scrapped after a certain amount of machining has been done on them, owing to the fact that they are then discovered to be porous. The expense of machining such useless castings must amount in course of time to a very considerable total. The fact that it is a simple matter to test them immediately on their receipt from the foundry, renders the waste referred to all the more inexcus able. The simple rig for testing the castings for porosity, which I affil about to describe, is one which is in use in several shops. It consists solely of a casting as shown in the sketch [which we have had redrawn.—ED.] large enough to hold the largest size piston with which the shop will deal. A. recess is east in the base, with a hole in the centre which opens into another passage, which must be drilled across from one side of the casting to the other. The piston is dropped into this recess, the open end downwards, and should rest on a leather washer. The casting is so arranged that when it is in this position it can be securely held by means of a set-screw from above, and pressed tightly enough on to the leather washer so as to prevent the leakage of oil, which is used as the testing medium. In order to avoid the possibility of 'cracking the piston when fixing it in position, it is advisable to interpose a pad between the end of the screw and the top of the piston, thus spreading the pressure over a greater area and reducing its intensity. With the piston thus secured oil can be pumped in by means of a small hand pump to any desired pressure. On a satisfactory conclusion as to the tightness of the piston being arrived at, this oil can be run off at the overflow tap shown and returned to the reservoir.

"If further refinement is required, this casting might be arranged to bolt down in the reservoir, in which the pump might also be fastened. By so doing the need for piping is, of course, obviated. I have used such a contrivance as this for some time now, with every success. It is neat, cheap, and can be operated very quickly. Almost any type of pump can be used, but a small, self-contained one is best."