AIDS TO SOLVING FORD PROBLEMS.

Page 43

If you've noticed an error in this article please click here to report it so we can fix it.

Valuable Advice on Every Phase of Ford Transport, which will Appeal to the Owner, Driver, and Repairer.

IN THIS series of hints concerning the Ford light chassis and ton truck wherever they are employed for commercial purposes, we endeavour to deal with the subject from every view-point, so . that the • advice given will appeal to the owner, driver, maintenance engineer, or mechanic. Valuable sources of information are being tapped for this purpose,and it should be understood that the information given will be derived from those with an intimate knowledge of the subject.

We shall welcome for inclusion amongst the hints these which have proved of value to individual users, and will make suitable remuneration for any published. What we desire are the results of -practice.

59.—The Gap of Sparking Plug Points.

The Ford is rather exceptional in more ways than one. For instance, on the average commercial vehicle engine the sparking plug points are separated by not more than 1-50 in., but in the Ford it is preferable that the plug points. should be separated by 1-32 in., as this prevents them from becoming oiled up too rapidly. The gap should not exceed this amount, as, otherwise it may cause an undue strain on the coils.

60.—Twisted Connecting Rods.

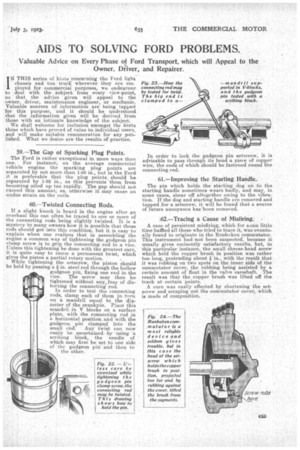

If a slight knock is heard in the engine after on overhaul this can often be traced to one or more of the connecting rods being slightly twisted. It is a, mystery to many. owners how it is possible that these reds should get into this condition, but it is easy to explain when one realizes that in assembling the engine a -common way of tightening the gudgeon pin clamp screw is to grip the connecting rod in a vice. Unless this tightening be done with the greatest care, it is quite easy to cause a permanent twist, which gives the piston a partial rotary motion. '

While tightening the setscrew, the piston should be held by passing a fin, steel rod through the hollow gudgeon pin, fixing one end in the vice. The screw may then be tightened without any.,,fea,r of distorting the connecting rod. In order to test the connecting rods, clamp each of them in torn on a mandril equal to the diameter of the crankpin. Place this mandril in V blocks on a surface plate, with the connecting rod in

horizental position and with the gudgeon pin clamped into the• small end. Any twist can now easily be ascertained. by -using a scribing block, the needle of which may first be set to one side of the gudgeon pin and then to the other.

In order to lock the gudgeon pin setscrew, it is advisable to pass through its head a piece of copper wire, the ends of which should be fastened round the connecting rod.

61.—Improving the Starting Handle.

The pin which holds the starting dog on to the starting handle sometimes wears badly, and may, in some cases, shear off altogether owing to the vibration. If the dog and starting handle are removed and tapped for a setscrew, it will be found that a source of future annoyance has 'been removed.

,62.—Tracing a Cause of Misfiring. ,

A case of persistent misfiring, which for some little time baffled all those who tried to trace it, was eventually found to originate in the Runla4ken commutator. This instrument had not been suspected, because it usually gives eminently satisfactory results, but, in this particular instance, the small cheese-head screw which held the copper brush in position was rather too long, protruding about in., with the result that it was rubbing on two spots on the inner side of the commutator cover, the rubbing being assisted by a certain amount of float in the valve camshaft. The result was that the copper brush was lifted off the track at certain points.

A cure was easily effected by shortening the setscrew and scraping out the commutator cover, which is made of composition.