REQUIREMENTS IN GULLY EMPTYING.

Page 13

Page 14

If you've noticed an error in this article please click here to report it so we can fix it.

The Advantages Offered by Mechanical Emptying. Some of the Difficulties that have been Experienced and are now Overcome. •

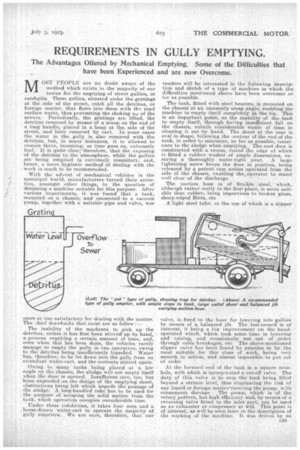

MOST PEOPLE' are no doubt aware of the method which exists in the majority of our towns for the emptying of street gullies, or catehpits. These gullies, situated under the gratings at the side of the street, catch all the detritus, or foreign matter, that flows into them with the road surface water, thus preventing the choking up of the sewers. Periodically, the gratings are lifted, the detritus removed by means of a scoop on the end of a long handle' placed in a heap at the. side of the street, and later removed by cart_ In some cases the water in the gully is also removed with the detritus, but, in many instances, it is allowed to remain there, becoming, as time goes on, extremely foul. It is quite clear,''therefore, that the exposing of the detritus to the atmosphere, while the gullies are being emptied ia extremely insanitary, and, hence, a more hygienic method Of dealing with the work is much to be recommended.

With the advent of mechanical vehicles in the municipal world, manufacturers turned their attention, amongst other things, to the question of designing a machine suitable for this purpose. After various experiments, it was found that a tank, mounted on a chassis, and connected to a vacuum pump, together with a suitable'pipe and valve, was

more or less satisfactory for dealing with the matter. The chief drawbacks that exist are as follow :— The inability of the machines to pick up the detritus, unless it has first been stirred up by hand, a process requiring a certain amount of time, and, even when this has been done, the vehicles rarely manage to empty the gully in one operation, owing to the detritus being insufficiently liquefied. Water has, therefore, to be Jet down into the gully from an attendant water-cart, and the contents stirred again.

Owing to many tanks being placed at a low angle on the chassis, the sludge will not empty itself when the door is opened. Insufficient care, too, hasbeen expended on the design of the emptying shoot, obstructions being left which impede the passage of the sludge: A long-handled rake has to be used for the purpose of scraping the solid matter from the tank, which operation occupies considerable time.

Under these conditions, it takes four men and a horse-drawn water-cart to operate the majority of gully. emptiers. We are sure, .therefore, that our

readers will be interested in the following description and sketch of a type of machine in which the difficulties mentioned above have been overcome so far as possible.

The tank, fitted with steel bearers, is Mounted on the chassis at an unusually steep angle, enabling the machine to empty itself completely at the tip. This is an important point, as the inability of the tank to empty itself, through having insufficient fall on the chassis, entails considerable waste ef time in cleaning it out .by hand. The shoot at the rear is oval in shape, following the -saintour of the end of the tank, in order to minimize, so far as possible, resistance to the sludge when emptying. The cast door is constructed with a recess, round the edge of which is fitted a rubber washer of ample dimensions, ensuring a thoroughly water-tight joint. A large tightening screw keeps the door in position, being released by a patent cam action operated from the side. of the chassis, enabling the,operator to stand well clear of the discharge.

The suction hose is of flexible steel, which, although rather costly in the first place, is more suitable than rubber, being im,pervious to broken glass, sharp-edged flints, etc Alight steel tube. at the top of which is a slipper valve, is fixed to the hose for lowering into gullies by means of a balanced jib. The last-named is of interest, it beirg a big improvement on the handOperated winch, which took some time in lowering and raising, and occasionally got out of order through cable breakages, etc The above-mentioned slipper valve has been found by practice to be the most suitable for this class of work, being very smooth in action, and almost impossible to put out of order.

At the forward. end of the tank is a square manhole, with which is incorporated a cut-off valve. The duty of this valve is to stop the tank being filled beyond a certain level, thus eliminating the risk of any liquid or foreign matter.entering the pump, wlth consequent damage. The .pump, which is of the rotary pattern, has high efficamey and, by•means of a reversing valve fitted to the inlet' port, can be used as an exhauster or ctimpressor at will. This point is of interest, as will be seen later in the description of the working of the machine. It was driven by an

enclosed drive from the top of the road gearbox. Lubrication is automatic, and a compound pressure and vacuum gauge situated at the rear of the driver's cab shows the operator what vacuum or pressure is in the tank.

A steel pipe with flexible joint connects the tank and pump, a safety valve being interposed, safeguarding the latter from over when used as a compressor.

The method of operation of this is as follows :—

Before commencing operations the tank is filled with, water to a level just above the entry of the Suction pipe, as shown by the dotted line in one of the sketches. When the first gully is reached, the driver, before dismounting, by means of a lever situated in the cab, puts the pump in gear. His assistant having removed the grating, pulls the pipe 'down into the gully. • The balanced jib enables this to be done quickly and easily. So soon as sufficient vacuum is attained, the suction valve is opened and the water in the gully, together with a certain amount. ot detritus, is drawn into the tank. The suction valve is closed and the driver moves the reversing valve through 90 degrees. This has the effect of altering the valve ports and turning the pump into a compressor. The air space above the liquid tank is raised in a few seconds to 5-10 lb. pressure per square inch, On the suction valve now being opened, a powerful stream of water churns IAA the sediment in the bottom of the gully, turning it into a semiliquid state. The operator at the gully closes the valve when the detritus has been sufficiently liquified, and the driver moves the reversing valve to its original position. A vacuum having once more been

attained, the gully is completely emptied.

-Some idea of the efficiency of the pump can be gained by the fact -that 15 ins. to 18 ins, of vacuum can be attained in 20 secs., the whole time taken in the operation of emptying the gully being just over a minute.

For refilling the gullies with clean water (a most, essential point) tanks are mounted, as shown, at the side of the main tank fitted with a quick-acting delivery valve and length of hose. These are .. filled by street hydrants when necessary.

As the main tank fills, the detritus settles at the bottom and the surplus water is drained away throngh the suction pipeinte 'the sewer: Only'sitidge is taken to the tip, thereby increasing the efficiency of the machine. There are some people who do_ not. believe in taking clean water to refill the gullies.It such cases the tanks at the side are dispensed with : a quickacting valve being placed near the forward end of the main tank, by which Means water is drawn off through a suitable length of hose. It is not clean, naturally, but, on the other hand,.it does not contain any detritus.. From the .foregoing description, it will be seen that, as the machine itself stirs tin the solid matter in the gullies,' it can efficiently be worked by two men. This does away with the third man, whose duty it was to stir up the sludge with -a rod, and also a horse-drawn water-cart and its driver. This Means that a very great saving is effected per annum, which is' a most important point in connection with the many and varied activities of municipalities. at the present day.