Dodge makes an assaul1 on the electric market

Page 16

Page 17

Page 18

If you've noticed an error in this article please click here to report it so we can fix it.

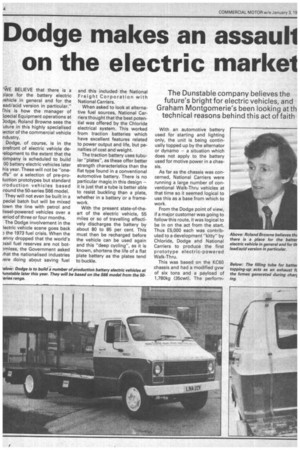

The Dunstable company believes the future's bright for electric vehicles, and Graham Montgomerie's been looking at th technical reasons behind this act of faith

'WE BELIEVE that there is a )Iace for the battery electric tehicle in general and for the ead/acid version in particular." rhis is how the manager of 3pecial Equipment operations at )odge, Roland Browne sees the uture in this highly specialised ;ector of the commercial vehicle ndustry.

Dodge, of course, is in the orefront of electric vehicle de,elopment to the extent that the :ompany is scheduled to build 00 battery electric vehicles later his year. These will not be "oneiffs" or a selection of pre-proluction prototypes but standard iroduction vehicles based round the 50-series S66 model.

They will not even be built in a pecial batch but will be mixed lown the line with petrol and liesel-powered vehicles over a ,eriod of three or four months.

The Dodge involvement in the lectric vehicle scene goes back the 1973 fuel crisis. When the enny dropped that the world's )ssil fuel reserves are not bot)mless, the Government asked /hat the nationalised industries (ere doing about saving fuel and this included the National Freight Corporation with National Carriers, When asked to look at alternative fuel sources, National Carriers thought that the best potential was offered by the Chloride electrical system. This worked from traction batteries which have excellent features related to power output and life, but penalties of cost and weight.

The traction battery uses tubular "plates", as these offer better strength characteristics than the flat type found in a conventional automotive battery. There is no particular magic in this design — it is just that a tube is better able to resist buckling than a plate, whether in a battery or a framework.

With the present state-of-theart of the electric vehicle, 55 miles or so of travelling effectively discharges the battery by about 80 to 85 per cent. This must then be recharged before the vehicle can be used again and this "deep cycling", as it is known, shortens the life of a flat plate battery as the plates tend to buckle. With an automotive battery used for starting and lighting only, the unit is being continually topped up by the alternator or dynamo — a situation which does not apply to the battery used for motive power in a chassis.

As far as the chassis was concerned, National Carriers were running a large number of conventional Walk-Thru vehicles at that time so it seemed logical to use this as a base from which to work.

From the Dodge point of view, if a major customer was going to follow this route, it was logical to be in on the act from the start. Thus £5,000 each was contributed to a development "kitty" by Chloride, Dodge and National Carriers to produce the first prototype electric-powered Walk-Thru.

This was based on the KC60 chassis and had a modified gvw of six tons and a payload of 1,780kg (35cwt). The perform in terms of traffic compatity (for example, speed and )eleration) was good and the licle had an operating range 72 to 88km (45 to 55 miles) on e eight-hour charge.

rhe first prototype had its 3king system modified in that 3 decision was made to adopt 3 Girling full power hydraulic stem. It was felt at the time it if the original Walk-Thru 3 king layout was to be rened, the size of electric pump cessary to keep the hydraulic stem fully pressurised would less drain on the battery than

electric-driven vacuum

The electric motor on the first ototype was installed in the )nt of the chassis complete th the controller, but on the concl version the motor was located amidships with the ,ntroller staying "under the mnet."

According to Roland Browne, ere was a lot of discussion for id against putting the motor in fect under the bodywork beruse of the problem of access. s the servicing requirements )r an electric motor are iinimal, Dodge took the gamble and it has paid off.

Having the motor in the middle of the chassis has given more room at the front for installing the controller, and it has also improved the weight distribution. No other changes were made to the vehicle — it was merely a question of swapping the mechanical driveline for an electric-powered one.

The first production batch of 16 electric Walk-Thrus was completed in 1978 alongside petroland diesel-powered versions on the Dunstable line. These were bought by major fleet operators — including National Carriers, Southern Electricity Board, W. Fi. Smith, Rank Hovis McDougall, and Unigate. This was followed in 1979 with a further batch of 55 being built and sold for field trials with further fleet operators — this time including SEGAS, Ever Ready, and several London boroughs as part of the Department of Industry sponsored London Goes Electric programme.

When the 50-series-replaced the Walk-Thru, the spadework had already been done. With the latter model, the braking system was not changed as it had been proved that the slight increase in

electric power to drive a vacuum pump was in fact negligible.

The biggest problem for Dodge has been finding space for the batteries. This has limited the choice of wheelbase for the electric 50-Series to 3.66m (12ft) and 4.04m (13ft 3in) because the necessary number of batteries can't be squeezed in on the shorter chassis.

To achieve the required body/payload capability of around 2.4 tonnes, it was necessary to go for the 566 model which has a gvw of 6.6 tonnes thus providing a graphic illustration as to the weight of batteries necessary to give the required performance.

Technical Details The Chloride batteries are of the lead/acid type rated at 420Ah Below: The Chloride batteries are housed in rubber-lined steel trays. The range provided is around 72 to 88km (45 to 55 miles) between charges. and housed in rubber-lined steE trays. They are fitted with th Chloride Autofil system for to ping up with distilled watel which allows rapid addition c water from one control point.

A fully automatic charge supplied with each vehicle, clE livers a full charge in eight hour and it is so programmed that it i impossible for the batteries to b overcharged irrespective of him long the vehicle stays connecte to the mains electrical system.

The drive motor is a 5016, compound-wound DC un specially designed to match th operating requirements of th vehicle. The transistorise electronic controller varies &I applied voltage across the mot( and the current through tlmotor employing a simile technique to that used in th more efficient type of fork Ii truck.

The controller operation based on high-speed electron switches which are used to val the percentage of time in whic the battery is directly connectE to the motor. If these switch( are off, there is no power flow all to the motor.

Opening and closing tlswitch rapidly — "rapidly" he meaning up to 500 times p second — varies the avera voltage applied to the motor ! the power is directly controll( by the relationship between tl "on" and "off" time of tl switches.

As a switch in theory is eith open or closed and in either co dition there is no power loss the switch, the efficiency of t system is high. This description invites comparison with a conventional ic engine especially when the latter is merely ticking over in heavy traffic without the vehicle moving.

If the electric vehicle isn't moving, it's not consuming energy.

Costing It has always been difficult to quote an initial price for an electric vehicle as the whole style of the exercise to date has been based on operational prototypes produced on a low volume basis.

With the electric-powered 50Series going into line produc:ion, albeit on a relatively small scale, some sort of price quota:ion is obviously essential.

A comparison with a conven:ional vehicle is made doubly iifficult because it is not possible to compare like with like in his instance. Though the 3lectric Dodge is based on the 366 model, it is essential to ..nake comparisons with the S46 )ecause this is the vehicle which t would replace on a payload )asis.

Any operator working in this weight sector and interested in he electric vehicle concept would probably be running die(el vehicles, which leaves us with a comparison based on the S46D versus the S66 electric.

The list price for the electric ,Dodge to be built later this year will be £14,625 but this figure is already a "1981 price". So it's necessary to modify the current price of £6,645 for the S46D to align with the situation in late '81.

Predicting the rate of inflation and its effect on vehicle prices is at best a matter of inspired guesswork, but I would estimate that a cost of £7,500 to £7,750 for an S46D would probably not be too far out by the end of this year.

Thus at the moment, the electric vehicle labours under a capital cost ratio of about 2 to 1 compared with a diesel. Dodge estimates that the future of the electrical concept in general will depend more on reducing this ratio to around 1.7 to 1 than on further development of lightweight batteries.

But initial cost is not the whole story. Included in the price for the electric Dodge is the cost of the charger, and it can also be argued that some of the battery outlay can be considered as running and not as capital cost.

Over the whole life of the vehicle, Dodge estimates that the electric model should be no dearer than the conventional variety due not only to the vastly reduced maintenance requirements, but also to the predicted longer vehicle life.

Ignoring chassis maintenance, which is the same for both types of vehicle, the main maintenance area for the electric model is battery care. These have the automatic filling system which can top them all up in one go.

Once each cell is full, it will shut itself off, with this process being repeated around the "cir cuit" of cells. The filling tube is then removed and returned to its usual position at the back of the cab where it acts as a vent for the escape of the gases produced during charging.

So even this is not a particularly labour-intensive operation.

Neither the motor nor the controller need very much in the way of maintenance, so this is a big plus for the electric vehicle.

It is difficult to predict just what will happen to the electric vehicle market in the future. The investment necessary for the manufacturer is going to be high and it needs a guaranteed mar ket. This is especially true in the case of a sodium/sulphur battery powered vehicle which will need a unique chassis built around a single-size battery pack.

The main areas of viability for electric vehicles, according to Roland Browne, are those of the light delivery van and urban passenger vehicle. This type of vehicle a good example being the 50-series could be built on a conventional production line with no extra labour and the minimum of extra training.

DC motors are expensive, but if AC motors could be made to work in this application then there could be a cost reduction. The famous microprocessor, which is cropping up almost daily in new situations, could be useful in the controller as part of a sophisticated energy management system.

According to Roland Browne on-board charging is also a pos sibility where the vehicle could have an AC motor plugged in a 13 amp three-pin circuit during the night, effectively acting as a generator. It could then be compatible on whole life cost terms with its conventional counterpart.

In the one ton to 30cv payload sector, people are a ready buying electric vehicle but not yet in any significar numbers as far as total mark( volume is concerned. LOWf down the weight scale, the pc tential volume for the electr vehicle is greater but th number of vehicles used by loci authorities is also greater an these are often needed for eme gency night calls which tend t disrupt an overnight chargin system.

As far as Dodge is concernec for an electric vehicle to be viable alternative it must be pal of a controlled operation wit the emphasis on "controlled".

It is one thing to build a electric vehicle, but it is anothe thing altogether to have it set viced. Dodge is primarily res ponsible for the whole vehicle but Chloride is looking after till servicing of its own compo nents.

In practice, if an operator has problem which he knows is defi nitely on the electrical side, ther he will contact Chloride direct otherwise it is via Dodge.

The marketing pattern for th( electric vehicle is now changinc according to Dodge truck sale: director Cyril Corke. Whereas ir the early days of his company': electrical vehicle involvemen. the pressure was generated b) Dodge salesmen who went ou. to sell, now this pressure is com ing from outside, from the mar. ket itself.

Cyril sees Dodge as being pri. manly in the 30cwt to two tor payload market. Above this, with the present state of battery de. velopment, it is far too easy tc go over the hgv weight limit.

Not that this is a problem from the engineering point of view but it would mean a fundamen. tar re-think by an operator if he suddenly needed to employ hg■., drivers on distribution work where it was previously unnecessary.