A NEW TWO-STROKE-CYCLE ENGINE.

Page 11

If you've noticed an error in this article please click here to report it so we can fix it.

An Interesting Power Unit, Hailing from Australia, which has Already Passed Severe Tests and Shows Considerable Promise.

VERY little progress has been made until recently in the development of the two-stroke engine for use on commercial motor vehicles. Innurnera,ble experiments have been carried out and fairly satisfactory designs evolved, but, in the main, these have all applied to the smaller types, and few have been venturesome enough to consider designing an engine sufficiently powerful for use in a transport vehicle. However, there is no doubt that there is a considerable field for such an engine if it can. be easily constructed, designed on

simple lines, and run without undue attention for considerable periods.

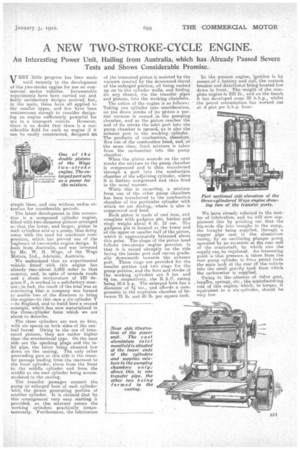

The latest development in this connection is a compound cylinder engine, fitted with two-diameter pistons arranged so that the lower, and larger, piston in each cylinders acts as a pump, thus doing away with the need for crankcase compression, which has proved one of the bugbears of two-stroke engine design. It hails from Australia, and was invented by Mr. W. H. Wege, of the Wege Motors, Adelaide, Australia.

We understand that ari experimental vehicle, fitted with this engine has already 'rum about 5,000 miles in that country, and, in. spite of unmade roads and a shade temperature of 120 degrees F., it worked in a satisfactory manner; in fact, the result of the trial was so convincing that a company was formed to enable two of the directors to bring the engine—in this case a six-cylinder V —to-England, and to build here a second example, which has now materialized in the three-cylinder form which we are about to describe.

The three cylinders are cast en bloc, with air spaces on both sides of the central barrel. Owing to the use of truncated pistons, they are rather higher than the conventional type. On the near side are the sparking plugs and the inlet pipe, the latter being situated low down on the casting. The only other protruding part at this side is the transfer passage leading from the rearmost to the front cylinder, those from the front to the middle cylinder, and from the middle to the rear cylinder being accommodated in the casting.

The transfer passages connect the pump or enlarged bore of each cylinder with •the power generating portion of another cylinder. It is claimed that by this arrangement very easy starting is provided, as the4 mixture enters the working cylinders practically instantaneously. Furthermore, the lubrication

of the truncated piston is assisted by the vacuum created by the downward-travel of the enlarged portion, oil being sucked up on to the cylinder walls, and finding its way thence, via the transfer pipes and pistons, into the working chambers.

The action of the engine is as follows: Taking one cylinder intoconsideration, on the down stroke of its piston a partial vacuum is caused in the pumping chamber, and as the piston reaches the end of its stroke the inlet port into the pump chamber is opened, as is also the exhaust port in the working cylinder. The products of combustion, therefore, flow out of the combustion head, and, nt the same time, fresh mixture is taken from the carburetter into the pump chamber.

When the piston ascends on the next stroke the mixture in the pump chamber is compressed and is Men transferred through is port into the combustion chamber of the adjoining cylinder, where it is further compressed and then fired in the usual manner.

While this is occurring, a mixture from one of the other pump chambers has been transferred to the combustion chamber of the particular cylinder with which we are dealing, where it also is compressed and fired.

Each piston is made of cast iron, and complete With gudgeon pin, bushes and rings weighs about 4 lb. 12 ow. The gudgeon pin is located at the lower end of the upper or smaller half of the piston, which is approximately balanced about this point. The shape of the piston head follows two-stroke engine practice, in that it is raised abruptly on the side facing the intake port and curves gradually downwards towards the exhaust port. Three rings are provided for the smaller portion and two rings for the pump portion, and the bore and stroke of the working cylinders are 3 ins. and 41. fits, respectively, the R.A.C. rating being 10.6 h.p. The enlarged bore has a diameter of 41, ins. and affords a compression in the explosion chamber of between 75 lb. and 85 lb. per square inch.

In the present engine, ignition is by means.of a battery and coil, the contact breaker and distributor being located low down in front. The weight of the complete engine is 250 lb., and en the bench it has developed .some 20 b.h.p., whilst the petrol consumption has worked out at .6 pint per b.h.p. hour.

We have already referred to the matter of lubrication, and we will now supplement this by pointing out that the big-ends dip into troughs in the sump, the troughs being supplied, through a copper pipe cast in the aluminium casing, by an oscillating plunger pump operated by an eccentric at the rear end of the crankshaft, by which also the supply can be -regulated. An interesting point is that pressure is taken from the rear pump cylinder to force petrol from the main tank at the rear Of the vehicle into the small gravity tank from which. the carburetter is supplied.

. Owing to the absence of Valve gear, tappets, springs, etc., the manufacturing cost of this engine, which, in torque, is equivalent to a six-cylinder, should be very low.