Temporary Winter Treads.

Page 4

Page 5

If you've noticed an error in this article please click here to report it so we can fix it.

Contributed by a User of Steam Wagons Fitted with Steel Tires.

Nothing, probably, acts as a deterrent to the more extended usc of motor lorries so much as the knowledge that with an ice-coated road ordinary steel-tired wheels will not " bite," and that the lorry will, in consequence, be rendered useless for the time. It is absolutely necessary, in many cases, to be able to guarantee delivery each day, and, although it may, rightly, be pointed out that absolute regularity is difficult with horse traction when snow or ice is encountered; it is not, as a rule, impossible, AFTER THE HORSES' SHOES HAVE BEEN SHARPENED,

which allows slow progress to be made in almost any weather, to place reliance upon it. Many people would be prepared to spend five to ten pounds on a motor wagon, in order to ensure such regularity of service in bad weather, during which periods they would, otherwise, be prevented from running the vehicle. It need scarcely be said that a remedy for this defect is the use of one of the excellent winter wheels which are now on the market, the principal of which have been described and illustrated in " THE COMMERCIAL MOTOR " (sec issue of June 22nd, tgo5). These, however, do not meet the cases with which the writer is now dealing, for, in the first place, they necessitate a greater outlay than has been. mentioned, and, in many cases, they take too long in the fixing. In a particular case, the changing of the wheels entailed

THE TAKING OUT OF THE BACK AXLE, with the result that, by the time the change was made, it often happened that the weather had itself supplied the remedy. Another point against regular winter wheels is that, if theyare to be very effective, the tires must consist of material which, in constant use, would wear rapidly. In theory, of course, they should only be used when absolutely required, but, in practice, when once on, they are likely to remain on until it is positively necessary to take them off for repairs, and, so, they are not ready for use if required again at short notice. This result, admittedly, is not as it should be, but, frequently, lack of supervision or want of time accounts for the occurrence. There are MANY ROUGII EXPEDIENTS, which will answer for a time in an emergency, but these are either not lasting or likely to lead the user into conflict with the authorities. The commonest of these, perhaps, is chain or rope wound round the tread. There is, in these cases, a difficulty in fastening the chain, whilst the rope wears out quickly. The writer well remembers having recourse to these methods in the early days of commercial motor vehicles, when a sudden freezing wind, following upon snow and a partial thaw, made the return of a lorry to the yard, after delivery of a load, a matter of the greatest difficulty. These means, however, enabled the driver to get back, and to keep up the record of a journey on every day throughout the winter.

The use of movable strakes or spikes is a breach of the regulations, and is not likely to be repeated in many districts.

One of the very best substances for gripping a slippery road, whether this is the result of ice, snow, or greasy mud, is, undoubtedly, rope. Could this be applied circumferentially with anything like ease, the whole question would be at once solved, but unfortunately the application is the difficulty.

A ROPE-COVERED WHEEL has been known to last a whole winter season, and, from this fact, a description of how it was put on may be of interest. The wheels, in this case, were built up of mild steel, and a section and elevation of the tire is shown in Fig. 1. First of all, two rings of small angle-iron, the exact diameter of the tire, were made, and these were forced on the tire so that the bottom side faced inwards, the outer face, in each case, being about ti inch from the edge of the tire : these angle-irons were riveted on to the tire itself, although, as the clips which were put on afterwards would have held them in position, it is doubtful if this was absolutely necessary. The space between the angles was a little under six inches in width, and in this was placed three rings of rope, each two inches in diameter. The difficulty arose as to how these ropes were to be held down, and the only way which seemed possible was by passing iron clips over them, as shown, the ends of these clips being bent over and passed through the tire. By means of nuts, the clips were tightened down to hold the ropes in place, and twelve such slips were used on a 39-inch wheel. The result was satisfactory for a time, and it would seem that, if the angle-rings were simply slipped on, as suggested, this method might be easily applied to any wheel. This modification would, also, allow the rope rings to be spliced much more readily than when in place on the tire. The difficulty of this arrangement, generally, is the clumsiness of the clips, and the small proportion of the face of the tire which is actually covered by the rope. In the colliery districts of Belgium, winding front the pits is done by means of large flat ropes, which are about five inches wide and rather over one inch in thickness. When these become defective in the slightest degree, they are, of course, replaced, and THE DISPOSAL OF THE OLD ROPE

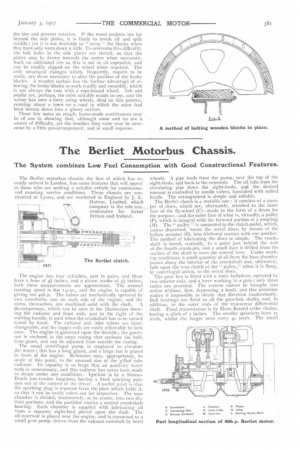

seems to be a matter of some difficulty. It a more satisfactory method of attachment to the tires of motor lorries could be devised, these ropes might, very advantageously, be used to form a winter covering. Some readers of "THE COMMERCIAL MOTOR," perhaps, may be able to point out a better way of dealing with the matter? There is an older form of temporary winter tread, which has been used with considerable success, and this consists of a removable wooden tire. The latter is placed round the ordinary wheel, and, although it causes the wheel to become five or six inches larger in diameter, this does not, usually, make any material difference. Fig. 2 Will help to explain the construction of this arrangement. Blocks of wood are

cut in segments, so as to fit the tire, each being to 3 inches thick : the best arrangement is to have eight of these to complete the circumference. There are four iron or steel plates on each side; each plate goes along the side of the whole of one wood segment, and over half of each of two others. These iron plates do not extend to the top of the wooden blocks, but go below the tire. The joints in them overlap, so that the end of one plate is opposite the centre of the one at the other side of the tire. Through the blocks and plates pass bolts, which allow the plates and wood to be bound together, and the whole to clip the tire and prevent rotation. If the wood projects too far beyond the side plates, it is likely to break off and split readily; yet it is not desirable to " scrap " the blocks when they have only worn down a little. To overcome this difficulty, the bolt holes in the side plates are slotted, so that the plates may be drawn towards the centre when necessary. Such an additional tire as this is not at all expensive, and can be readily slipped on the wheel when required. The only structural changes which, frequently, require to be made, are those necessary to alter the position of the brake blocks. A wooden surface has the further advantage of allowing the brake blocks to work readily and smoothly, which is not always the case with a rope-bound wheel. Ash and poplar are, perhaps, the most suitable woods to use, and the writer has seen a lorry using wheels, shod on this pattern, running about a town on a road in which the snow had been beaten down into a glassy surface. These few notes on rough, home-made contrivances may be of use in showing that, although snow and ice are a source of difficulty, yet the troubles they raise may be overcome by a little pre-arrangement, and at small expense.