THE TANGYE OIL ENGINE TRIED OUT

Page 40

Page 41

Page 42

If you've noticed an error in this article please click here to report it so we can fix it.

Technical Description of the Tangye VM6 Engine; Omo Patent Combus tion Chamber Gives a High Measure of Efficiency and Smooth Running

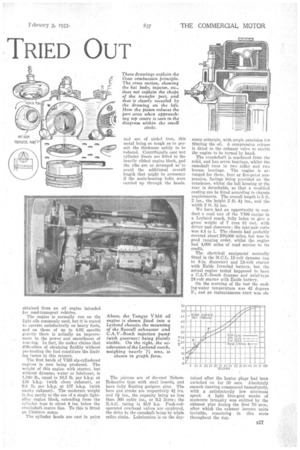

THE main feature of the Tangye pre-combustion oil engine for road vehicles, which was described briefly in a preliminary article in The Commercial Motor on September 2, 1932, is the Omo patent combustion chamber. This incorporates a hot body, or bowl, and a transfer passage of peculiar form, the combination producing a condition of controlled turbulence on the compression stroke.

As will be seen from the accompanying cross-section diagram and sketch, the air above the piston is able to pass through a passage of large area into the hot body ; this condition holds until the piston approaches the top of its compression stroke, when the area of the passage is reduced by the piston itself, and at this stage high velocity and turbulence are created. It has been demonstrated photographically, we are told, that practically all the first part of the combustion takes place either in the hot body or in the transfer port, and not over the piston, which rises to within about 1-32 in. of the flat head. As the flame propagates and the piston descends, free action is given to the expanding gas.

An important feature is that the air, in entering the hot body, is divided into two streams, and it takes up heat from the mass of insulated metal. As injec tion begins, the velocity of the air is maintained, the compressed-air streams cutting the oil spray at right-angles.

Another important point is the raising of the temperature of the hot body and its maintenance at the correct temperature. The body itself is made of a beat-resisting alloy called Nicrosilal, • B26

and its weight is ro' oz. It is surrounded by a small air space, being held in by a screw cover of aluminium alloy, with which it makes contact through only a moderate area. The screw cover is vaned to dissipate excess heat, and although the hot body takes up heat rapidly when the engine is started, yet

it does not rise in temperatnre above a dull red heat, even with prolonged running. In short, it rapidly adjusts itself to the varying conditions of load, and it is clearly seen that the necessity of heating up a large water-cooled area before combustion can take place is obviated.

An interesting feature about the performance curves of the engine is that the company differentiates between performance with an invisible exhaust and maximum performance that is obtained with a smoky exhaust, which might not be permitted in service. It is a particularly fair way of publishing results obtained from an oil engine intended for road-transport vehicles.

The engine is normally run on the light oils commonly used, but it is stated to operate satisfactorily on heavy fuels, and on those of up to 0.92 specific gravity there is actually an improvement in the power and smoothness of running. In fact, the maker claims that difficulties of obtaining fluidity without pre-heating the fuel constitute the limit" ing factor in this respect.

The first batch of V1416 six-cylindered engines is now being produced. The weight of this engine with starter, but without dynamo, water or lubricant, is 1,340 lb., equal to 10.3 lb. per b.h.p. at 130 b.h.p. (with clean exhaust), or U.S lb. per b.h.p. at 137 b.h.p. (with smoky exhaust). The moderate weight is due partly to the use of .a single lightalloy engine block, extending from the cylinder tops to about 4 ins, below the crankshaft centre line. To this is fitted an Elektron sump.

The cylinder heads are cast in pairs. and are of nickel iron, this metal being so tough as to permit the thickness safely to be reduced. Centrifugally east wet cylinder liners are fitted to the heavily ribbed engine block, and the ribs are so arranged as' to avoid the additional overall length that might be necessary if the main-bearing bolts were carried up through the heads.

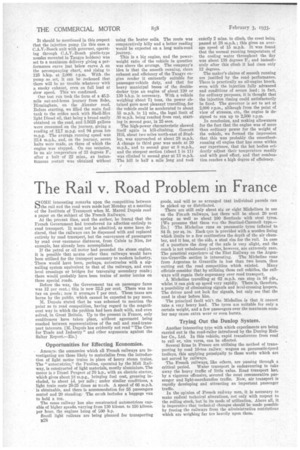

Above, the Tangye VM6 oil engine is shown fitted into a Leyland chassis, the mounting of the Reavell exhauster and C.A.V.-Bosch injection pump (with governor) being plainly visible. On the right, the acceleration of the Leyland coach, weighing nearly 71 tons, is

shown in graph form.

The pistons are of die-cast NelsonBohnalite type with steel inserts, and have fully floating gudgeon pins. The bore and stroke are respectively 44 ins. and 61 ins., the capacity being no less than 566 cubic ins., or 9.2 litres; the R.A.C. rating is 45.9 h.p. Push-rodoperated overhead valves are employed, the drive to the.camshaft being by triple roller chain. Lubrication is on the dry

sump principle, with ample provision for filtering the oil. A compression release is fitted to the exhaust valve to enable the engine to be turned by hand.

The crankshaft is machined frem the solid, and has seven bearings, whilst the camshaft runs in two roller and two bronze bearings. The engine is arranged for three, four or five-point suspension, facings being provided on the crankcase, whilst the bell housing at the rear is detachable, so That a modified casting can be fitted according to chassis requirements. The overall length is 5 ft. 2 ins., the height 3 ft. 4.i ins., and the width 2 ft. 3* ins.

We have had an opportunity to conduct a road test of the VM6 engine in a Leyland coach, fully laden to give a gross weight of 7 tons 81 cwt. with driver and observers ; the rear-axle ratio. was 4.4 to 1. The chassis had probably ' covered about 200,000 miles, but was in good running order, whilst the engine had 4,000 miles of road service to its credit.

The electrical equipment normally fitted is the M.C.L. 12-volt dynamo (up to 8-in. diameter) and 24-volt starter with Exide Ironclad battery, but the actual engine tested happened to have a C.A.V.-Dosch dynamo and axial-type 24-volt starter with Exide battery.

On the morning of the test the cooling-water temperature was 42 degrees F., and an instantaneous start was oh tamed after the heater plugs had been switched on for 30 secs. Absolutely smooth running commenced immediately, with a satisfactorily low minimum speed. A light blue-grey smoke of moderate intensity was emitted by the ekhaust pipe during the first 70 secs., after which the exhaust became quite invisible, remaining in this state throughout the day. It should be mentioned in this respect that the injection pump (in this case a C.A.V.-Bosch unit with governor, operating through C.A.V.-Boseh pintle-type nozzles mounted in Taugye holders) -was set to a maximum delivery giving a performance curve just below curve A on the accompanying chart, and rising to 325 b.h.p. at 2,000 r.p.m. With the pump so set, it can be reckoned that there will be no trouble whatever with a smoky exhaust, even on full load at slow speed. This we confirmed.

Our test run took the form of a 45.2mile out-and-home journey from Soho, Birmingham, on the Aleester road. Before starting, we filled the main fuel tank to the orifice neck with Shell-Max light Diesel oil, that being a brand easily obtained on the road, and 3.5025 gallons were consumed on the journey, giving a reading of 1.7 m.p.g. and 94 gross ton m.p.g. The average running speed was 22.4 m.p.h., and, on the journey, seven halts were made, on three of which the engine was stopped. On one occasion, in an air temperature of 33 degrees F., after a halt of 22 mins., an instantaneous restart was obtained without using the heater coils. The route was comparatively hilly and a better reading would be expected on a long main-road journey.

This is a big engine, and the powerweight ratio of the vehicle in question was above the average. The company's idea is that the smooth running, clean exhaust and efficiency of the Tangye engine render it eminently suitable for passenger-vehicle duty, and that for heavy municipal buses of the doubledecker type an engine of about 120 or 130 b.h.p. is necessary. With a vehicle weighing about 74 tons, the power obtained gave most pleasant travelling, for the vehicle could be accelerated to about 55 m.p.h. in 1f min,, the legal limit of 30 m.p.h. being reached from rest, starting in second gear, in 25 secs.

The high-power characteristic showed itself again in hill-climbing. Gorcott Hill, about two miles north-east of Studley, was approached at about 28 m.p.h. A change to third gear was made at 20 m.p.h., and to second gear at 8 m.p.h., and the steepest section (about 1 in 11) was climbed in second gear at 13 m.p.h. The hill is half a mile long and took

exactly 2 mins. to climb, the crest being passed at 28 m.p.h.; this gives an average speed of 15 m.p.h. It was found that the normal running temperature of the cooling water throughout the day was about 138 degrees P., and immediately after this climb it had risen only 12 degrees.

The maker's claims of smooth running are justified by the road performance. There is practically no oil-engine knock, even with the injection fully advanced and conditions of severe load; in fact, for ordinary purposes, it is thought that the injection timing could satisfactorily be fixed. The governor is set to act at 2,000 r.p.m., although from the point of view of stresses, etc., the engine is designed to run up to 2,500 r.p.m.

In conclusion, and making allowances for the fact that the engine was of more than ordinary power for the weight of the vehicle, we formed the impression that this was probably the smoothestrunning oil engine that has come within our experience, that the hot bodies evidently adjust their temperature readily and with good effect, and that combustion reaches a high degree of efficiency.