Engines (II). The Continental.

Page 4

Page 5

Page 6

If you've noticed an error in this article please click here to report it so we can fix it.

The Second of a Series of Articles Dealing with the Power Units Employed on Many of the Commercial Vehicles of To-day.

The second of this series, as is meet, deals with the products of one of our trade rivals across the Atlantic, an American company. The country of its origin, being, as it is, the home of the assembled chassis, is obviously the place where one would find specialization in chassis units at its zenith, and nowhere in that country is such an outstanding example to be found as at the works of the Continental Motor Manufacturing Co. at Detroit, Michigan, U.S.A. This company is probably the largest in the world of those making petrol engines only. Its impor. tance may be roughly estimated from the fact that it claims to supply the engines for 80 per cent. of the commercial-vehicle chassis manufactured in the United States. From an intimate knowledge of the design and specifications of such machines, we are inclined to agree this figure. The further knowledge, that more than 90 per cent. of American-made " trucks " are assembled from units of this nature tends rather to increase one's resPect for an organization capable of supplying the power for so many vehicles. In round numbers, the engineselivered monthly by this Ilk company ceed, we believe, 4000 complete. units.

The Continental engine was very

little known to British commercialvehicle users before the war, the Whiting-Federal lorry, perhaps the principal assembled marketed

" truck " at that time, being fitted with it. In touring-car circles it was fairly well-known, as several chassis embodying it were in use over here ; the R.C.H., Pathfinder and Hudson are naines which occur to us in passing. There were others, which we do not at the moment recall.

Although the company graduated in the school of touring-car design, it has by now had a large and varied experience of heavy-vehicle requirements, extending over a number of years, and for that reason should be in a position efficiently to cater for the needs of the commercial user. In effect, the models which we are about to describe, and examples of which we have seen in this country on many of the chassis for the sale of which agencies have been established over here, are described as "the Continental line of commercial-vehicle motors."

To British eyes, accustomed as they are to the substantially-built power units of this country, engines that have, so far as their principal dimensions go, been evolved, rather than designed, by a process of elimination of errors and weaknesses which have shown up in the course of hard work, and in many cases, of overwork ; the appearance of Continental machines, as well as a perusal of their specifications, give the impression of lightness, often translated as touring-car-ism. The difference in practice, however, between engine-builders here and those of the States, may be, to some degree, corrected, and a proper perspective obtained, if the following facts, which affect the basic principles of design, be thoroughly understood.

British commercial-vehicle experience of value is of greater age than American. Business motors were made and used here, to a considerable extent, before the very arduous conditions of such service were known, and, which is of greater consequence in respect of the present discussion, before the highclass steels now so commonly used in automobile construction were so available, or their advantages in

this regard fully realized. As a result, the dimensions of important

details, and especially of bearing surfaces, crankshafts,' 'gudgeon pins, and similar parts, increased until the factor of safety Was suffitient for the materials in vogue. Afterwards' . with the, advent of better steels, it was difficult to persande an established maker to reduce his sizes accordingly, and quite a few British engines err on the generous side in this respect, if at all.

The designer in the States, on the other hand, came into the field at a time when more progress had been made in this matter ; he realized early the advantage of being able to use steel of a tensile strength exceeding the ordinary by 100, and BOIlletimes 200, per cent., and worked accordingly.

If will be realized, therefore, that a difference between the actual dimensions of the parts of an engine made here and one constructed on the other side of the Atlantic, while implying, we think, the probability of longer life to the homebuilt, unit, does not, on the, other hand, lead one to draw the inference that early demise Of the " truck " engine may be expected. The latter will probably perform satisfactorily if treated fairly, but will not stand the same overloading as its more robust brother.

As might be expected, the Continental engine is, in general, up•-todate in its design and construction ; one or two features, as for ex

ample, the lubrication system, are not in accordance with what is regarded on this side as the best practice, but on the whole it is a very sound power unit.

Four. models form what we have referred to above as the line of commercial-vehicle models. Of these three are supplied in two types, and as-each is made in a variety of sizes, it will readily be understood that we could, were we so disposed, devote quite a large amount of space to enumerating these.

It will suffice if we, by way of a' summary, • indicate that the sizes' range from 4 in. by 5 in. to 51 in. • by 51 in. bores and strokes respectively. The styles covered are three and four-point suspension, attachment to main frame or sub-framc, thermo-syphon or pump circulation: of the cooling water, and arrange-' meat for independent gearbox or' unit power Plant. Other sub-divisions there are also which allow of different heights of the engine in the frame different widths of engine bed, and so on ; these concern the designer rather than the user. With one or two exceptions, these. engines are arranged so that the addition of electric generating,: lighting or starting sets is a simple affair. VIC provision of agovernor. is also inade optional.

To consider the design in detail,' the cylinders are cast en tilde in the: smaller Models, and in pairs for the larger ones. Great care is taken to eliminate faulty castings, and each is set aside for a time after rough' baring, so as to eliminate the effects of distortion due to machining. strains. • The water jacket heads, are cast separately, being afterwards attached by bolts. By this means ease of access is had to the inside the -jacket for cleaning out the cores, etc. • The. valves are in line along one side 'ofthe engine, being operated -by. one camshaft through. the medium of adjustable tappets. They are 'interchangeable, and are made with heads of nickel steelWelded on to mild-steel Stems. All the valve .

gear is enclosed by removable metal plates : these serve to silence the noise from the tappets.

The pistons are of good length, and are fitted with three concentric rings near the top. The gudgeon pins are hollow, and hardened and ground ; each is held in the piston bosses by a simple locking device. On these pins the bronzebushed little ends of the connecting rods bear. The latter are of H see Con, and the big ends are fitted with. white metal-lined bronze bushes, held in place by caps fastened by bolts of nickel steel. The crankshaft has three journals, bearing in white-metal-lined bushes similar to those in the con

fleeting rods ; it has flanges formed on it to take any end thrust. Ball thrust washers are not fitted.

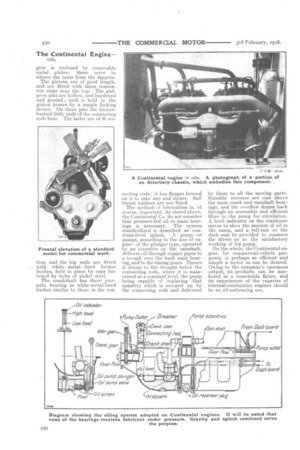

The method of lubrication is, of course, important. As stated above, the Continental Co. do not consider that pressure-fed oil to main bearings is necessary. The system standardized is described as constant-level splash. A pump—or pumps, according to the size of engine—of the plunger type, operated by an eccentric on the camshaft, delivers oil through copper pipes to a trough over the back main bearing, and to the timing gears. Thence it drains to the troughs below the connecting rods, where it is maintained at a constant level, the pump being capable of replacing that quantity which is scooped up by the connecting rods and delivered

by them to all the moving parts. Suitable recesses are cast above the main crank and .camshaft bearings, and the overflow drains back through an accessible and efficient filter to the pump for circulation. A level indicator on the crankcase serves to Billow the amount of oil in the sump, and a tell-tale on the dash may be provided to reassure the driver as to the satisfactory working of his pump.

On the whale, the Continental engine, for commercial-vehicle purposes, is perhaps as efficient and simple a motor as can be desired. Owing to the company's enormous output, its products can be marketed at ,a reasonable figure, and its experiences of the vagaries of internal-combustion engines should be an all-embracing one.