AMERICA UTOMOTIVE THOUGHTS

Page 42

Page 43

Page 44

Page 47

If you've noticed an error in this article please click here to report it so we can fix it.

The Summer Meeting of the Society of Automotive Engineers took place in Atlantic City, New Jersey, in June. Certain of the numerous papers dealt with are summarized below, these dealing principally with vehicle corrosion resistance, experimental fourwheel designs, engines and lubricants.

Corrosion Resistance

SOME SIX PAPERS were presented dealing with problems of corrosion, mainly in vehicle bodywork, and various interesting conclusions were reached. In one of the more important papers. Mr. R..1. Saxon, manager of the Advanced Body Development Department of the Ford Motor Co.'s metal-stamping division, detailed the research which had led to the widespread adoption of galvanized steel by his company. It is estimated that in 1962 the Ford Motor Co. will make use of about '135,000 tons of galvanized steel, whilst the rest of the American automotive industry will use about 200,000 tons. Prior to 1959, galvanized steel was used principally for lock assemblies, seat tracks and headlamp dishes, but since 1960 this material has been used increasingly for body and underframe main members and other structural components.

Mr. Saxon commented that the increased interest in corrosion protection for commercial vehicles, as well as for cars, was due principally to the increased use of salt on city streets during winter months, the growing adoption of chassisless construction for light vehicles and—surprisingly

• —greater use of light-coloured exterior paints. it was pointed out that, although paint had always been considered a good and relatively inexpensive means of corrosion protection, to be effective the coating of paint had to completely cover the area to be protected and, to achieve this, individual parts ought to be painted before assembly. This was impracticable, however, because of subsequent welding operations.

Painting after assembly did not ensure coverage in shielded or enclosed areas, 'neither could these areas• be inspected. Dip painting appeared to be the answer, but a phenomenon known as refluxing occurred during the drying process and this was responsible for loss of paint coverage on some inside surfaces. Mr. Saxon said that it was generally agreed that water was one of the principal contributors to corrosion, and he said rust was virtually unknown in dry climates, such as desert areas. When water is present in any form other items combine with it to accelerate the corrosion process, probably the most serious of these being chemicals.

Abrasion caused by dust, dirt and mud added to the problem and the boxed members, flanges and pockets encountered in modern body designs tended to trap dirt along with moisture and salt. For this reason such members in Ford vehicles were made of galvanized steel.

During the course of evaluating the relative merits of various corrosion-resisting materials and methods, a comprehensive test programme was established. So far as organic coatings were concerned, various primers, metallicrich paints, plastic coatings, foaming materials, greases and waxes Were tried out. It was shown that any coating which was applied prior to forming a part had the disadvantage that the coat could be removed or damaged, whilst if the coatings were applied after forming, but before assembly, considerable space was required for application and curing. Coating after assembly resulted in inadequate or uncertain protection.

Stainless steels, copper-bearing steels and other low-alloy steels were evaluated also, but these were generally discarded as being either too expensive or ineffective.

Well-ventilated, well-drained members were tried, but appeared that increasing the air flow through a box secti did not have the advantages claimed.

Several different metallic coatings were then tried. Ter plate was found not to have all the qualities desired protecting body steels, and was somewhat expensive. 1 plate also was relatively costly and did not possess all desired qualities. Cadmium plating, used with success small parts, was not available on wide sheets, it IA difficult to weld and again its cost was high. Aluminii cladding, although used extensively for exhaust silence was found to be difficult to weld.

Early on in the programme, however, the merits of zi

coatings for protecting body steels became apparent. Bc electro-deposited zinc and hot-dipped galvanized mater were investigated, but for various reasons it was decided concentrate on developing the use of hot-dipped materia coating adhesion being good and the natural lubricati properties being advantageous for press work. Initia welding 'caused some trouble, but eventually a material developed by the Weirton Steel Co. (division of I National Steel Co.) which had a thinner zinc coating one side of the steel than on the other: 0.0001 in. cornpar

with 0.001 in. '

Problems were encountered with regard to painti galvanized steel, the paint adhesion and resistance blistering being poor. An improved phosphating systi was developed which was compatible with both zi coating and the Ford enamel paints.

' All in all, the results showed that galvanized steel was be preferred because (a)it had superior corrosion resistan (b) being coated at the mill its quality and consister could be assured and handling did not reduce its effecti. ness, (c) it was adaptable to the usual methods of formn drawing, welding and painting, and (d) it was economic However, zinc-rich and other rust-resistant primers worn continue to be used on some parts requiring corrosion pi tection, whilst undercoatings would still be applied underbody areas subjected to stone spray from the wher Mr. Saxon concluded by saying that„whilst Ford's had ma substantial progress towards resisting rust in commerc bodies, considerable further efforts were still being devoi to the problem.

Beating Rust by Trial and Error HOW THE Michigan Bell Telephone Co. claimed have solved the problem of rust deterioration in 4,600-vehicle fleet was explained in Mr. Gilbert H. Selli paper. " Operation Anti-Rust." The author explained tl the company had not been scientific in its approach to 1 problem, and that the success achieved had been the res of trial-and-error techniques. Like Mr. Saxon, Mr. Se pointed out that much of the corrosion damage sustair could be put down to the use of salt to control ice a

now: this was a big problem in the case of Mr. Selke's :empany for, as he said, "Detroit is built practically on op of a salt mine," as a result of which the Michigan Bell ust-damage repair bill came to approximately £28,000 per 'ear, mostly on rocker panels, door bottoms, corner posts, vings, floors, headlamp nacelles, wheel arches, and so orth.

Mr. Selke said, "You may ask what was left, and this zads to some other costs that were not so obvious. We rave spent money many times for tune-ups that finally urned out to be pinholes in gas lines. We have had brake ines rust through and rupture." He went on to the effect hat, as they studied their problem, they began to feel that here were mischief makers other than salt. Identical chides working in different areas were rusting at different needs and in different spots: airborne chemicals and mud ad to be taken into consideration and it was reasoned, dmittedly unscientifically, that certain soils contained rustrovoking chemicals which increased washing frequencies Id not counter.

A great deal of the rust encountered was coming from lside boxed-in areas, and even keeping the drain holes pen did not provide a cure. Experiments were therefore orted with various products that were marketed as rust reventives: "In fact, I think we tried about everything lat we were told would stop rust from Swedish gun oil witchcraft Some of the things we tried looked good, and me smelled good. Then there were those that didn't look ood and didn't smell so good either. This may sound ke a joke but, believe me, it was no joke. If you put )me material on a vehicle and a driver decides he doesn't ke the smell you have new problems."

Rust holes were found in wings, the undercoating of • hich appeared to be sound. When the undercoating was :moved, however, it was found that corrosion was already t work, so painting the undersides of the wings was tried. ,lthough this enabled it to be readily discerned whether re underside of the wing had been properly washed, sound:adening effects were lost and the paint was liable to be lipped off, leaving bare metal exposed.

The problem was discussed with many manufacturers and :troleum companies, and eventually Texaco " L " coin3und was chosen because, even though it did not meet all le Michigan Bell specifications, it did not violate them to ich a degree that the compound ought to be rejected. he one unfavourable characteristic of Texaco "L" was ; high viscosity, but this problem was solved by using an riess spray gun which could supply the compound at -essures of between 2,000 and 3,000 p.s.i.

The method used to apply Texaco" L " was first to steamean the vehicle and then, when it was dry, drill holes in e boxed-in sections so that the insides could be coated. low-viscosity compound was used for the interior ctions, and a heavy compound for general undercoating. Dr parts that were already rusty, a mixture containing :xaco "L," S.A.E.10 lubricating oil, a cleaning solvent id a releasing oil were used, although as this mixture was und to attack rubber components care was needed to .oicl such parts.

laval Attack on Corrosion

THE MILITARY ASPECT of this problem of corrosion ts detailed by Mr. James E Doran and Mr. Paul C. organ, both of the Bureau of Yards and Docks Depart ment of the Navy. It was explained in this paper that, in 1958, the U.S. Navy established a corrosion-control programme as a means of extending the service life of vehicles in tropical and sub-tropical areas. Studies revealed that trapped moisture and a combination of salt and heat, plus heavy concentrations of sand and marl, produced complete rusting away of wings and lower door sections, corrosion under rubbing rails and in insulated areas, excessive deterioration under floor mats, and complete deterioration of exterior paint within 12 to 18 months.

Much of the corrosion occurred on surfaces that had previously been painted or coated by the vehicle manufacturers and it was noted that the interiors and door panels had been lightly fogged with primer, but that, because of the many bare spots, the primer was completely ineffective. The end result was the development of special techniques for the application of preservative material to the sections of vehicles that were most vulnerable to corrosion, and the coatings recommended, which were relatively inexpensive, were all stocked in the U.S. Navy supply system, these ranging from asphalt varnish to sodium chromate.

The general method of application was to remove various chassis and body components, such as the fuel tank, exhaust system, seats, lights and so forth, and then to steam-clean all accessible surfaces, and brush and scrape the body interior, after which the appropriate coatings could be applied as specified. It was clearly demonstrated that maximum protection was possible in an environment where most severe corrosion occurred, that the cost of processing vehicles with special coatings was about £47 per vehicle, that vehicle service life was doubled without major body repairs and that maintenance required to achieve effective protection was minimal.

Four-wheel-drive Designs •

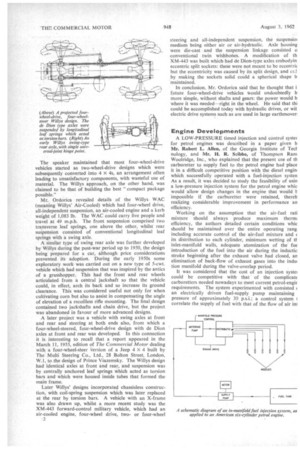

A PAPER DELIVERED by Mr. M. Ordorica, of Willys Motors, Inc., dealt with the work that this company had done on lightweight 4 x 4 vehicles, particularly with regard to the use of independent suspension systems. Mr. Ordorica explained that, from the work that the automotive industry had carried out through the years, it was evident that an independent suspension arrangement was superior to the solid-axle system, primarily because the location of the roll centre could be chosen to suit requirements rather than it being placed arbitrarily at wheel-centre level. Furthermore, independent suspension gave maximum comfort. The speaker maintained that most four-wheel-drive vehicles started as two-wheel-drive designs which were subsequently converted into 4 x 4s, an arrangement often leading to unsatisfactory components, with wasteful use of material. The Willys approach, on the other hand, was claimed to be that of building the best "compact package possible."

Mr. Ordorica revealed details of the Wiltys, WAG (meaning Willys' Air-Cooled) which had four-wheel drive, all-independent suspension, an air-cooled engine and a kerb weight of 1,083 lb. The WAC could carry five people and travel at 49 m.p.h. The front suspension comprised two transverse leaf springs, one above the other, whilst rear suspension consisted of conventional longitudinal leaf springs with a swing axle.

A similar type of swing rear axle was further developed by Willys during the post-war period up to 1950, the design being prepared for a car, although price considerations prevented its adoption. During the early 1950s some exploratory work was carried out on a new type of 5-cwt. vehicle which had suspension that was inspired by the antics of a grasshopper. This had the front and rear wheels articulated from a central jackshaft so that the vehicle could, in effect, arch its back and so increase its ground clearance. This was considered useful not only for when cultivating corn but also to assist in compensating the angle of elevation of a recoilless rifle mounting. The final design contained two jackshafts and chain drive, but the project was abandoned in favour of more advanced designs.

A later project was a vehicle with swing axles at front and rear and steering at both ends also, from which a four-wheel-steered, four-wheel-drive design with de Dion axles at front and rear was developed. In this connection it is interesting to recall that a report appeared in the March 11, 1955, edition of The Commercial Motor dealing with a four-wheel-steer version of a Jeep 4 X 4 built by The Multi Steering Co., Ltd., 28 ,Bolton Street, London, W.1, to the design of Prince Viazemsky. The Willys design had identical axles at front and rear, and suspension was by centrally anchored leaf springs Which acted as torsion bars and which were housed inside tubes that formed the main frame.

Later Willys' designs incorporated chassisless construction, with coil-spring suspension which was later replaced at the rear by torsion bars. A vehicle with an X-frame was also drawn up, whilst a more recent study was the XM-443 forward-control military vehicle, which had an air-cooled engine, four-wheel drive, twoor four-wheel steering and all-independent suspension, the suspensioi medium being either air or air-hydraulic. Axle housing were die-cast and the suspension linkage consisted o conventional twin wishbones. A modification of th XM-443 was built which had de Dion-type axles embodyin eccentric split sockets: these were not meant to be eccentrir but the eccentricity was caused by its split design, and ct,I by making the sockets solid could a spherical shape b maintained.

In conclusion, Mr. Ordorica said that he thought that i future four-wheel-drive vehicles Would undoubtedly b more simple, without shafts and gears: the power would b where it was needed—right in the wheel. He said that thi could be accomplished today with hydraulic drives, or wit electric drive systems such as are used in large earthmover

Engine Developments

A LOW-PRESSURE timed injection and cantrol systet for petrol engines was described in a paper given b Mr. Robert L. Allen, . of the Georgia Institute of Teel nology, and Mr. H. R. Scibbe, of Thompson Ram Woolridge, Inc., who explained that the present use of th carburetter to supply fuel to the petrol engine had place it in a difficult competitive position with the diesel engirt which successfully operated with a fuel-injection systen As a result, it was decided to study the feasibility of usin a low-pressure injection system for the petrol engine whic would allow design changes in the eneine that would impossible if the carburetter were retained, thereb realizing considerable improvement in performance an efficiency.

Working on the assumption that the air-fuel rati mixture should always produce maximum therm efficiency, the authors detailed certain conditions whk should be maintained over the entire operating rang including accurate control of the air-fuel mixture and its distribution to each cylinder, minimum wetting of ti inlet-manifold walls, adequate atomization of the fur introduction of the fuel into the air during the inductic stroke beginning after the exhaust valve had closed, an elimination of back-flow of exhaust gases into the indu tion manifold during the valve-overlap period.

It was considered that the cost of an injection systei could be competitive with that of the complicatc carburetters needed nowadays to meet current petrol-engit requirements. The system experimented with consisted an electrically driven fuel-supply pump maintaining pressure of approximately 30 p.s.i.; a control system correlate the supply of fuel with that of the flow of air ml inlet manifold; a threeor five-cylinder radial variableoke metering pump; and a distribution system integral h the metering pump which receives fuel at a steady e from this pump and which. divides the total flow tally, delivers these equll increments to the proper inders in a timed sequence that coincides with the induc n strokes of the engine and atomizes the fuel adequately. is distributor is of the rotating-disc type.

The results of tests with this equipment were entirely isfactory, and fuel savings of up to 15 per cent, when imared with the standard carburetter engines were tamed.

etrol-diesel Combinations EN A PAPER entitled "Hybrid Engines," prepared by r. Paul H. Schweitzer, of Schweitzer and Hussmann, and r. Lawrence J. Grander, of the Richfield Oil Corp., empts to improve the fuel consumption of petrol engines combining petrol-engine features with those of the diesel gine were described, and the authors felt that the olutionary efforts at present being made in this direction )uld no doubt be rewarded by the introduction of a perior form of motive power in the foreseeable future. The major objective of hybridization techniques in gine design was to achieve the improved low-load fuel Dnorny of the compression-ignition engine without losing lightness, smoothness, quietness and clear exhaust of the ark-ignition unit. Having dealt briefly with known types fuel injection, the authors went into considerable detail out " stratified charge " systems, such as those capable separating rich and weak mixtures, the basic concept ing that an overall lean fuel-air mixture can be burned lciently providing a controlled richness around the ark ing plug is given when the spark occurs.

A stratified-charge engine effects a lower flame temperare, improved cycle efficiency, less heat loss, less isociation, less pumping loss and less air pollution, r Harry Ricardo having been generally credited with monstrating the combustion of very lean mixtures by use a combustion cell The paper then went on to describe rious stratified-charge systems such as the Meyer, 'oderson, Texaco, Witzky, Nilof, Heintz, Hesselman and • Renault.

Experiments carried out in the research laboratories of e Pure Oil Co. indicated that exploration of the -atified-charge principle provided greater potential than nverifional spark-ignition-engine development to more Iciently convert hydrocarbon fuels into mechanical ergy at part loads. Furthermore, the system appeared be less fuel sensitive and did not recognize anti-knock may as a factor of major importance, nor volatility as a imary motor-fuel specification.

Artother group of hybrid engines dealt with were those hich were basically diesel engines but having one or more Arol-engine features, such as throttling of the intake air id external mixing of the fuel and air. The German -system and various multi-fuel designs were considered so. The authors concluded that the sharp distinctions :tween petrol and diesel engines would gradually disap:ar and that the internal-combustion engine of the future ould have the best features of the diesel engine and petrol [gine working compatibly together. part, field tests carried out with taxicab fleets to determine what advantages were to be gained from the use of engine oils containing ashless detergents which could nevertheless retain the more desirable properties of ash-forming detergents, improve the control of sludge as developed under intensive stop-and-start conditions, and eliminate or reduce unwanted ash.

Continuous high-load tests were made with commercialvehicle petrol engines, using Supplement 1 metallic sulfonate-phenate oils and an oil containing an ashless detergent. Each of the vehicles was operated fully loaded at full throttle, and averaged 60 m.p.h. for 30,000 miles. At the end of this time there was a marked difference in the amount and nature of the combustion-chamber deposits, the ashless-detergent oil showing only a thin dark film with no piston erosion, whereas the metallic-detergent oil showed much heavier deposits and the pistons had eroded top edges, indicating incipient surface-ignition damage.

It was concluded that, in addition to excellent control of stop-and-start sludge, ashless detergents gave the subsidiary advantages of reducing the octane requirement of an engine, reducing surface-ignition tendency and reducing the risk of ash causing valve failures.

Additives—Another View

IN CONTRAST, a paper written by Mr. L. A. %Reynold g and Mr. Bill Mitacek, both of the Phillips Petroleum Co., implied that ash-containing additives provided greater flexibility for overall quality in formulating engine oils, whilst certain ash-containing materials offered a superior balance of overall crankcase-lubricant performance. Tests carried out with two ash-containing oils and one ashless oil in a high-compression V-8 petrol engine indicated no significant difference in combustion-chamber, and pistoncrown deposits with any of the oils. although the oil with the highest ash content produced significantly less deposit on the inlet valves and ports. Furthermore, it was shown that the higher the ash content, so the lower the engine octane requirement.

Low-temperature-performance tests showed that, although the ashless oil reduced sludge formation and cam wear, it tended to aggravate the formation of rust and varnish. High-temperature-performance tests indicated that the oil with the greatest ash content gave the best piston cleanliness.

The authors came to the conclusion that engine oils of equal upper-cylinder performance quality could be formulated with ash-containingor ashless oil additives: that ash-containing and ashless additives were available to provide effective control of low-temperature sludge deposits; ash-containing additives were superior to ashless in high-temperature detergency effectiveness: and ashcontaining additive formulations were available that gave better overall balanced oil performance than was currently possible with the ashless additives tested.