aving Money with an "Artie Conversion

Page 44

Page 45

Page 46

Page 47

If you've noticed an error in this article please click here to report it so we can fix it.

By John F. Moon

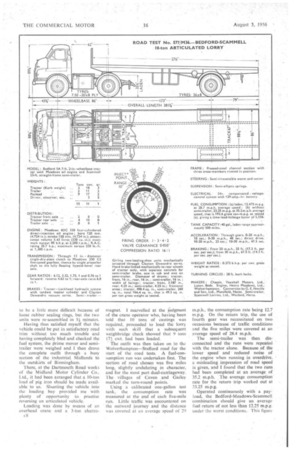

BEDFORD-SCAlvIMELL 10-ton articulated outfit, powered by a Meadows oil engine, proved on test to be highly satisfactory. The cost of the engine conversion, which was carried out by 0. E. Neville and Son. Ltd.. is extremely reasonable by today's standards, and this highly rnanceuvrable combination has an economical and lively performance.

The test vehicle was the latest addition to the :fleet of W. Blamire, Ltd.. Langton, Lanes, and hi its three weeks of service had covered 2,800 miles.. Mr. Blarnire, who began irt 1935 with a 1-ton lorry and now has a-fleet of 50 vehicles, already has another Bedford SA prime mover with a Meadows power unit-and five more Bedfords on order will be similarly converted before being put into service.

The Neville conversion, in which a special engine-mounting kit is used, is reasonably straightforward. Two versions are offered. With the cheaper one the original Bed ford gearbox is retained and the ' complete change-over costs an operator £600 15s., of which £400 12s. 6d is accounted for by the Meadows 41.3C 330 engine complete with all accessories.

• A fuller conversion is available at £722 15s. and for this figure a Meadows 250 C5 five-speed gearbox is included: this box coSts £128 101.. complete with clutch and bell housing. For prime movers already fitted with trailer coupling gear,.the conversion price is £5 less if the vacuum tank is fitted by the coupling manufacturers.

Saving of £120 Cost of conversion could be partially offset by the price realized on the sale the unwanted engine arid gearbox, and in the case of the BedfordSA chassis this 'is about £120 for conspoisents in new condition.

Assuming the average laden fuelconsumption rate of the BedfordMeadows outfit to be 12.25 m.p.g., there is a fuel-cost saving of 4.13d. per mile over a petrol-engina version which could normally be expected to return. about 6.125 m.p.g. It should therefore be possible to cover the increased outlay within 35,000 miles, or after 42,000 miles if the operator does not realize on the petrol engine. This mileage would be reduced to 30,000 if the Bedford gearbox were to be retained in conjunction with the Meadows engine.

The Meadows engine offered in the conversion is a 5.43-litre four-cylindered unit with a maximum output of 85 b.h.p: at 2,200 r.p.m. Current versions of this engine have been uprated to give a power output of 90 b.h.p, at 2.400 r.p.m. In both, the maximum torque is 230 lb.-ft.

Three types of Meadows 250 C5 gearbox are available. All have five speeds and that fitted • to the test vehicle had an overdrive-top ratio of 0.76 to 1. The standard alternative has a direct top gear and closer fourth and third c6

ratios,. whilst there is a special underdrive gearbox whieh,has a low tiatio of 8,05 to I.

For normal laden running with Ole 20 rn.P.h. speed limit, the overdrive-top gearbox is not so suila hie as the directdrive-top model, This is also the opinion of Mr. -Blarnire, who has ordered his five new vehicles with the latter gearbox.

As the speed limit is likely to he raised next year to 30 m.p.h., the over drive gearbox might prove more favourable, particularly with operators in areas that are not too hilly.

With the standard Bedford axle ratio of 6.8 to 1, the overdrive box gives a maximum road speed of approximately 45 m.p.h. when running on the governor at 2,200 r.p.m., whereas in direct. drive the maximum speed. is 34 m.p.h. Whilst the close-ratio direct-drive-top gearbox will be most suitable for working in hilly districts, the overdrive box should prove satisfactory for all normal working with the 30 m.n.h. limit in force when running unladen the advantages of the overdrive are Obvious.

Other than the modifications to the original engine-mounting brackets and the provision of a new engine coWl. the prime mover was unchanged by the conversion. A 40-gal. fuel lank, in preference to the standard 26-gal, unit, had. however, been fitted by Mr. Mathire, as much of the work done by his fleet is long-distance hau2age between Cdas

-gow, Longton and London. '

The Searnmell 23-ft. straight-frame semi-trailer, with platform body and headboard, has been in Mr. Blainire-s service for over a year.

As-both prime mover and semi-trailer had just been taken out of service for Foy test, I felt justified in carrying out the. maintenance tasks first, so that attention could be given to the b•rakes, batteries, filters and other components likely to affect the test results.

It took 14 seconds to check the level. of the water in the radiator, and the engine-oil level was verified in 55 seconds. A trap has been provided in the neat-side cowl to give access to the dipstiek, but this is slightly to the rear of the desired position, with the result that the stick only just clears the a pet ure.

A combined filler and level plug is provided on the near side of the gearbox and by using this the level was checked in 45 seconds. The gearbox holds a gallon of lubricant and engine oil is suitable for it. The recommended grade is S.A.E 30. I checked the level of the oil in the rear axle in 14 minutes; a delay being caused by a tight' thread on the plug.

The, bonnet top is arranged to hinge backwards and can be: opened its this way in 4 seconds. The hinge pin cab be withdrawn, however, and in this way the complete top assembly can be detached in 14 seconds. This gives clear aecess to the top and near side of the poper unit.

With the bonnet .detached, the four injectors were removed in 8 minutes, some delay .being caused as the result of several of the copper washers binding on the union threads. The injectors were replaced in 7 minutes, the whole job being straightforward.

Tappet adjustment was carried out in the total time of 91 minutes.

There is no provision on the chassis for the use of a starting handle, so the engine was turned over by jacking up the rear wheels and turning the propeller shaft with third gear engaged. The &compressor was lifted while turning the engine. The time given includes jacking up the wheals. and removing and replacing the bonnet, Brake adjustment proved to be surprisingly simple. Using the hydraulic jack provided in the tool kit to raise both wheels of each axle simultaneously, the rear brakes were adjusted in the total time of 1 minute 26 seconds, the large internal adjusters being turned by hand through the large back-plate apertures.

A slightly longer time was required for the front wheels because of the difficulty of siting the jack under the centre of the front-axle heath, but adjustment was completed in 2 minutes 45 seconds.

With the assistance of a Meadows fitter, the complete braking system was blcd in 5 minutes, the rear units taking 21 minutes. The only difficulty about this job was that spanners of different sizes are required on the bleeding nipples of each axle.

Battery-level checks occupied a total of II. minutes. There are two 6v. batteries under each seat in the cab and these may be reached by complete removal of the seat cushions and pans.

The oil-bath oil-cleaner, which is a Bedford fitting, is located above the radiator stack and reached through the water-filler trap. Its position is, therefore, a trifle cramped and removal and replacement of the cover to check the oil level in the bowl occupied 21 minutes.

There are three fuel filters in the system: a primary filter Located on the inside of the near-side frame member and twin main filters at the rear of the cylinder block on the near side. The two elements in the primary fuel filter were removed in 11 minutes, including the time taken to clean out the sludge trap in the filter housing: The two main filters were reached from behind the cab and both elements were removed in the total time of 2.1 minutes. Replacement proved to be a little more difficult because of loose rubber sealing rings, but the two units were re-assembled in 5+ minutes.

Having thus satisfied myself that the vehicle could be put in satisfactory road trim without too much trouble and having completely bled and checked the fuel system, the prime mover and semitrailer were weighed and I then drove the complete outfit through a busy section of the industrial Midlands to the outskirts of Birmingham.

There, at the Dartmouth Road works of the Midland Motor Cylinder Co., Ltd., it had been arranged that a 10-ton load of pig iron should be made available to us. Shunting the vehicle into the loading bay provided me with plenty of opportunity to practise reversing an articulated vehicle.

Loading was done by means of an overhead crane and a 3-ton electroc8 magnet. I marvelled at the judgment of the crane operator who, having been told that 10 tons of castings was required, proceeded to load the lorry with such skill that a subsequent weighbridge check showed that 9 tons cwt. had been loaded.

The outfit was then taken on to the Wolverhampton—Stafford road for the start of the road tests. A fuel-consumption run was undertaken first. The section of road chosen was five miles long, slightly undulating in character, and for the most part dual-carriageway. .1-he villages of Coven and Galley marked the turn-round points.

Using a calibrated one-gallon test tank, the consumption rate was measured at the end of each five-mile run. Little traffic was encountered On the outward journey and the distance was covered at an average speed of 29

m.p.h., the consumption rate being 12.7 m.p.g. On the return trip, the use of fourth gear was necessitated on two occasions because of traffic conditions and the five mils were covered at an average speed of 211.4 m.p.h.

The semi-trailer was then disconnected and the runs were repeated with the tractor alone. Because of the lower speed and• reduced noise of the engine when running in overdrive, a misleading impression of road speed is given, and I found that the two runs had been completed at an average of 35.2 m.p.h. . The average consumption rate for the return trip worked out at 23.25 m.p.g.

Operated continuously with a payload, the Bedford-Meadows-Scammell combination should give an average fuel return of not less than 12.25 m.p.g. under the worst conditions, This figure

is substantiated by Mr. Blamire's own experience with the vehicle in service. If a fair amount of unladen nmning is included in the operator's schedules, the consumption rate should improve to the region of 16-17 m.p.g.

Using a stretch of dual carriageway at Coven, the braking tests were next carried out. Good as the figures were, they might have been improved had the payload been placed farther forward. With the weight distribution as tested, the front-axle loading was on the light side and this caused front-wheel locking when making emergency stops, although not to the detriment of stability.

For the same reason, the rear wheels of the prime mover locked on one occasion when braking from 30 mph. The resulting skidding is reflected in the reduced deceleration rate from 30 m.p.h., when compared with that from 20 m.p.h. There was only slight surec present in the system, as indicated by the comparison between the maximum deceleration recorded by the Tapley meter and 'the average deceleration measured in terms of braking distance. . Despite the relatively low power-toweight ratio, the acceleration of the outfit from a standing start was particularly satisfactory and for these tests I used second, third and fourth ratios. When pulling away from 10 m.p.h. in direct drive there were no signs of excessive vibration in the engine or transmission, and the resulting acceleration times, Which are high for this class of vehicle, reflect the good low-speed torque characteristics of the power unit.

Gradient Tests Two hill climbs were made. The first was at Holloway Hill, Tettenhall Wood, where there is a maximum gradient of approximately 1 in 6. The stop-start test in low ratio on this section was so successful that I took the outfit round the corner to Old Hill, where there is a maximum gradient near the top of 1 in 5, the average gradient of the climb being 1 in 8.

A non-stop climb was completed with ease, and I then drew up on the off side of the road where the gradient is steepest, to see whether the lorry would be able to start. Before attempting to pull away, I checked the efficiency of the hand brake and was gratitied to find that the tractor hand brake alone would hold the vehicle on this slope. All too frequently it has been found during tests of vehicles of this type that application also of the semi-trailer brake is necessary.

Although the outfit did manage to pull away on this gradient, there was an abundance of clutch slip, even with my foot right off the pedal.

I was well satisfied with the performance of the outfit during all these tests and, bearing in mind that there are three sets of gearbox ratios available. it should suit most conditions of operation anywhere in this country. The tractor is pleasant to drive, the gearchange action being particularly smooth and easy.