MOBILE LUN DRIES Do th Vashing

Page 26

Page 27

Page 28

If you've noticed an error in this article please click here to report it so we can fix it.

FOR IF

TROOPS

MOBILE laundries evolved by the mechanical engineering branch of the Royal Army Ordnance Carps are being used to keep the troops supplied With clean clothes in places where arrangements cannot be made with commercial laundries. This facility will be particularly valuable on active service. As they come out to rest, men will be able to bathe in a mobile wash-house and then obtain clean clothes from one of the laundries on wheels.

Already, several complete laundry units have been placed in service and many more are on the way, so that conditions for men on active service should be more comfortable than they were from 1914-18. This all helps towards efficiency and keeps up the morale of the troops.

Those who know nothing of the complexities of modern laundry engineering may regard this casually as just another service on wheels. The public has come to accept without question the success of even the most unlikely uses of road vehicles. But investigation of the launderer's angle, as well as the transport aspect of this innovation, shows that the equipping of a laundry convoy with intricate interconnected apparatus, sufficiently compact to be housed in trailers of handysize, is a feat of engineering worthy of more notice than a cocked eyebrow.

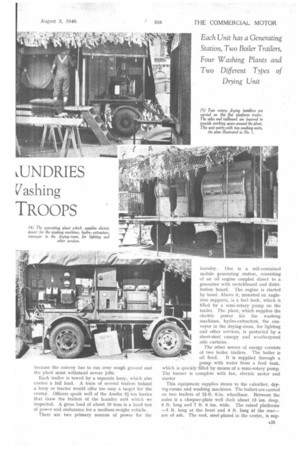

Nine four-wheeled pneumatic-tyred trailers are required to carry the plant of a complete laundry. The vehicles all have steel frames, large-diameter turntable rings, triangular drawbars, overrun brakes on the front wheels, and detachable screw jacks to steady them while on laundry duty. Their average weight is 51 tons, The washing equipment, up-to-date and necessarily small and complicated, is, at the same time, sturdy, because the convoy has to run over rough ground and the plant must withstand severe jolts.

Each trailer is towed by a separate lorry, which also carries a full load. A train of several trailers behind a lorry or tractor would offer too easy a target for the enemy. Officers speak well of the Austin 3i-ton lorries that draw the trailers of the laundry unit which we inspected. A gross load of about 10 tons is a hard test of power and endurance for a medium-weight vehicle.

There are two primary sources of power for the laundry. One is a self-contained mobile generating station, consisting of an oil engine coupled direct to a generator with switchboard and distribution board. The engine is started by hand. Above it, mounted on angleiron supports, is a fuel tank, which is filled by a semi-rotary pump on the trailer. The plant, which supplies the electric power for the washing machines, hydro-extractors, the conveyor in the drying-room, for lighting and other services, is protected by a sheet-steel canopy and weatherproof side curtains.

The other source of energy consists of two boiler trailers. The boiler is oil fired. It is supplied through a pump with water from a feed tank, which is quickly filled by means of a semi-rotary pump. The burner is complete with fan, electric motor and starter This equipment supplies steam to the calorifier, drying-rooms and washing machines. The boilers are carried on two trailers of 13-ft. 0-in. wheelbase. Between the axles is a chequer-plate well deck about 13 ins. deep, 8 ft. long and 7 ft. 6 ins. wide. The raised platforms —5 ft. long at the front and 4 ft. long at the rear— are of ash. The roof, steel-plated in the centre, is sup ported on a light tubular frame, and weatherproof curtains hang all around.

The calorifier is carried on the boiler trailer and supplies water direct to the washing machines. Tubes passing through the calorifier carry steam from the boiler, and heat the water fed from the cold tank. Thence, the hot water passes to the washing plant.

The actual washing is done in four trailers. Each carries a rotary washing machine, a hydro-extractor and a soap boiler. Each washing machine is constructed entirely of metal. A sliding door is interlocked to prevent its being opened when the brass inner cage is revolving or closed when the hand gear is in use. An electric motor, mounted low down in the trailer, drives the washing machine and another motor the hydro-extractor.

Hydro-extraction is the launderer's high falutin name for the first stage of drying. Wet clothes are placed in a rapidly revolving cage and centrifugal force throws them to the outside. This process draws off practically all water and the garments are merely damp when removed. The hydro-extractors used in the mobile laundries are self-balancing.

All steam and water pipes are brought to one point on each trailer, so that outside connections can be made easily.

The 3-ton trailers used for the washing units have oak-framed bodies with ash floors. The front panel is fixed, but the sides and tailboard, which are about 3 ft. high, are hinged and, when lowered, rest on stout adjustable legs. Use of the sides and tailboard gives a floor length of 18 ft. and a width of 13 ft. 3 ins. A detachable waterproof tilt is mounted on a.light removable tubular framework.

Another trailer carries a continuous drying-room. Clothes are passed through this room on an electrically driven conveyor, on which they are held by easily loaded

clips of corrosion-resisting alloy. A lever can be set to release the clips automatically, so that the clothes fall into a basket when they have completed one revolution of the room. The conveyor can be stopped by pressing a button readily accessible to the feed operator.

The heating battery is steam operated and lint can easily be removed from its radiating surface by blowing with a rubber hose connected to the steam pressure supply. Insulated walls and roof are provided. The trailer is similar in general construction to the washing units, and has a hinged platform for the operators, and a rigid canopy.

Continuous drying is particularly suitable for woollens, because it reduces the risk of shrinking.

Apart from the drying-room already described, there is a trailer equipped with two rotary drying tumblers. Externally, a tumbler is not unlike a fish-frying oven, and clothes revolve in it while they are dried by hot air. The equipment is placed longitudinally down the trailer, and when the sides and tailboard, are lowered there is ample working space.

When the laundry is in, service, the trailers can conveniently be parked in two lines of three, with a boiler unit on each flank and the generator set at the head. At a recent demonstration, one line consisted of a dryingroom and two washing units, with the attendant boiler plant on the flank. In the other line were the two remaining washing units and the tumblers, again with their boiler unit. Each little group of four is self-c:ontained, apart from the supply of power from the central generator.

Although these mobile laundries have had their teething troubles and their design has given those responsible a few headaches, they have now reached a practical stage of development and the Royal Army Ordnance Corps is proud of them.