HINTS ON MAINTENANCE.

Page 28

If you've noticed an error in this article please click here to report it so we can fix it.

How to Get the Best out of a Vehicle, to Secure Reliability and to Avoid Trouble.

701.—Obviating a Trouble with a 1916 Vulcan.

Inthe 1016 Vulcan the worm-driven axle has a cap (A), which is of brass, cup-shaped, and used for adjusting the thrust race at the rear of the worm shaft.

One of our contributors experienced a lot of trouble With the six setscrews which are supposed to prevent this cap from moving. of becoming loose.

These setscrews had a habit

However, a cure was effected by replacing the original screws by six others, each having a deeper head and drilled right through with a t-in, hole, so that they could be wired up together after fitting.

Also, it was discovered that the rear thrust race did not obtain sufficient lubricant, so be made certain of supplying an adequate amount by removing the cap (A) and drilling and tapping a *-in. gas hole in the centre of the hexagon, fitting a Stauffer lubricator (B) into it.

702.—Utilizing Serviceable Ball Races.

In case of necessity badly worn and broken ball races can sometimes be replaced from stock, either new or second-hand, providing the races to be fitted are ;n good condition, and it is not essential that they should be of the exact size of those which are to be replaced. In such circumstances, where the inner diameter of the replacement race is too large, a mild steel, or even a hard brass bush, may be turned to fit the bore of the race and the shaft on which it is to operate.

Where the outer diameter of the ball race is smaller than the housing into which it is to be fitted, a carefully machined packing ring may be employed. Sometimes even a combination of the two methods will he found useful, although care should be taken to see that the correct clearances or fitting sizes are maintained.

Deficiency in the width of a race can be made up by utilizing a metal disc of mild steel or hard brass, which can quickly be made in a small lathe. This disc must, of course, be bored out to clear the spindle, and should be given a slight clearance on the face so that rubbing does not occur between it and the moving ring."

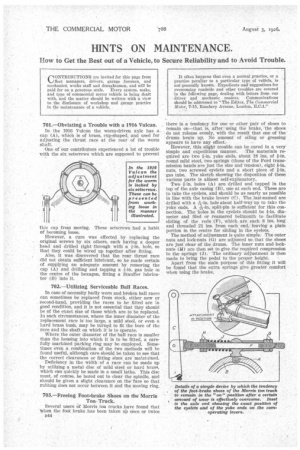

703.—Freeing Foot-brake Shoes on the Morris TonTruck.

Several users of Morris ton trucks have found that When the foot brake has been taken up once or twice E44 there is a tendency for one or other pair of shoes to remain on—that is, after using the brake, the shoes do not release evenly, with the result that one of the drums heats up. No amount of oiling or greasing appears to have any effect.

However, this slight trouble can be cured in a very simple and expeditious manner. The materials required are two 4-in. yoke ends, about 18 ins. of Fin. round mild steel, two springs (those of the Ford transmission bands are just the size and tension), eight

nuts, two screwed eyelets and a short piece of 1-in. gas tube. The sketch showing the disposition of these various parts is almost self-explanatory.

Two j-in, holes (A) are drilled and tapped in the top of the axle casing (B), one at each end. These are to take the eyelets, and should be as nearly as possible in line with the brake levers (C). The last-named are drilled with a hole about half-way up to take the yoke ends. A -A-in. split-pin is sufficient for this connection. The holes in the eyelets should be 4-in. diameter and filed or reamered bellmouth to facilitate sliding of the rods (F), which are each 8 ins, long and threaded 21 ins, from each end, leaving a plain portion in the centre for sliding in the eyelets.

The method of adjustment is quite simple.. The outer nuts and lock-nuts (G) are adjusted so.that the shoes are just clear of the drums. The inner nuts and locknuts (Id) are then set to give the required compression to the springs (J). The ordinary adjustment is then

made to bring the pedal to the proper height, . Apart from the main purpose of this fitting it will be found that the extra springs give greater comfort when using the brake.