PARA VAN EETS A SPECIAL NEED

Page 48

Page 49

Page 50

Page 51

If you've noticed an error in this article please click here to report it so we can fix it.

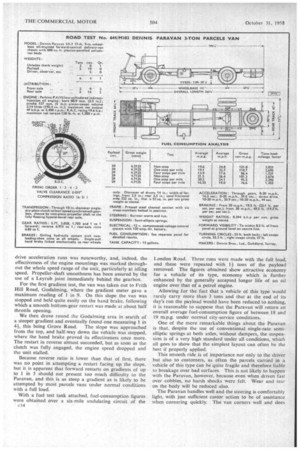

First Test of Dennis Paravan 3-ton ParcelsDelivery Van Shows Adequate Performance for City Work, with Quite Favourable Fuel Economy : Front-end Layout Assists Driver to Speed Deliveries By John E Moon,

RESULTING from an extensive study of the requirements of parcels and other smalls carriers, the Dennis Paravan 3-ton chassis has been laid out with the specific object of increasing overall delivery efficiency without having to resort to the use of unorthodox chassis components.

Th result is that the Paravan has completely adequate performance for the type of service envisaged, but what is more important is that the driver (who in nine cases out of ten is also the rounctsman) has first-class driving conditions and maxim-um accessibility to the payload with the minimum of physical effort.

I have been able to make the first road test of one of the new Paravans, the vehicle tested being that exhibited by Dennis Bros., Ltd., on their stand at the Commercial Motor Show last month. This vehicle is the .second to have been built for Essex Carriers, Ltd,, South Benfleet, Essex, whose managing director, Mr. R. B. Brittain, was largely instrumental in getting together with Dennis to formulate the design of such a vehicle. The first Paravan was fully described and illustrated in The Commercial Motor on August 8, 1958.

Many of the features of the Paravan, particularly with regard to the bodywork, are similar to those suggested by Mr. Brittain and myself in the story published in The Commercial Motor on June 20, 1958, including the. idea of a corner-front entrance, a clear front platform, a 3-ft. 6-in, loading height, and a half-width aperture behind the driving compartment to give access from the platform to the goods compartment.

These bodywork features make it possible for the driver to enter or leave his vehicle from either the front or the kerb side—useful when drawn up close alongside another object on the near side—and the platform and step layout into the body proper is such that, except when exceptionally large parcels have to be off-loaded, all deliveries can be made without the driver going round to the back of the

cll vehicle. This in turn means that the rear shutter can remain locked throughout the whole of the delivery run, and thus help to safeguard against pilfering.

To meet these bodywork requirements and at the same time keep the chassis layout as simple as possible, the Dennis designers adopted a similar frame layout to that of the Stork chassis. Unlike the Stork, however, which .had an underfloor engine, the Paravan chassis has its Perkins P.4 (V) power unit mounted vertically above the front axle so that it lies on the centre-line of the chassis but

behind the line of the driver's seat.

The engine is mounted fairly high in the frame so as to give a high degree of accessibility—far .better than is possible with an underfloor:engined layout—and because the engine cowl is only about 2 ft. 6. in. wide, there is adequate room to the left of it for the driver to Pass between the goods compartment and the front of the vehicle. • In other respects, the layout of the Paravan chassis is conventional, the dropped front extension being similar to that used on the Stork chassis and including a deep Z-member to give rigidity to the front of the chassis. Although the front-end framing has been developed with the object of providing a corner front entrance, there is no• reason why a conventional side door could not be used instead if an operator so desired.

Similarly, the maximum chassis width has been kept down to 6 ft. 5-12i in. over the rear tyres, making it possible to build bodywork with a maximum width not exceeding 6 ft. 9 in. Wider bodies could easily be mounted, however, although most parcels carriers are agreed that 6 ft. 9 in. is about the widest that can be managed with some of the narrow streets that such vehicles have to negotiate.

. Indeed, during the test it was noticeable how " slim" the Paravan seemed when manceuvring through some of the Guildford back streets, and some of the gaps through which it Was taken looked a tight squeeze for a private car, let alone a 3-ton van.

Colour-impregnated Plastics

The body of the Paravan • tested was interesting for its use of flat, colour-impregnated plastics panels, the first Paravan delivered to Essex Carriers, Ltd., having aluminium panels. The use of colour-impregnation spells a considerably longer life for the livery of the vehicle as scratches do not remove the colour; this was shown during the test when the vehicle was driven close to some overhanging trees which scraped down the length of the body but which did not leave a mark.

Also noteworthy is the fact that the colour of the plastics panels was virtually identical to that of the paint used on

4 the aluminium panels on the front of the van and on the door. These panels were prepared by Rydgeway Plastics, Ltd., London, E.7, and the side panels are in two pieces, although the vertical joint is difficult to detect. The signwriting is not impregnated.

The roof of the Paravan also is of plastics and the centre section of this, measuring 16 ft. by ft. and extending forward over the driving seat, has been left transparent because it has been proved time and time again that the greatly improved visibility inside the body can save anything up to two hours a day on a delivery round because the driver does not have to fumble to find a particular, parcel.

In licensing condition, the Paravan offered for test weighed 2 tons 17 cwt., and complete with full tanks, Spare

wheel and so forth, its kerb. weight was 3 tons cwt., the

rear axle loading being 1 ton 74 cwt. Sandbags and iron weights totalling 2 tons 19 cwt. had been added and complete with Mr. E. C. Scott, Mr. L. Jackson (both of Dennis) and myself aboard, the full-load testing was carried out at a gross running weight of 6 tons 41 cwt.

Assuming that the Paravan will be operated with a driver by himself, this means that the test was carried out with an equivalent payload of 3 tons 2 cwt, or thereabouts.

For the braking tests the van was taken out to the Peasmarsh, where there is an adequate length of level road. The Girling braking system is not assisted, despite which good retardation figures were obtained, the additional pedal effort required being partly compensated for by the complete lack of delay in braking reaction because of there being no servo. A Hydrovac servo can be fitted to order.

From each of the two speeds at which tests were made, the Paravan pulled up smOothly without deviating from a straight course and only from 20 m.p.h. were there any signs of wheel locking, these being from the rear tyres. The hand-brake efficiency was shown to be high, 35 per cent. being obtained from 20 m.p.h. The lever is short and its travel small, but it is well placed to enable maximum purchase to be obtained on it.

The acceleration figures obtained are quite reasonable in view of the relatively small power unit, and the standingstart times were undoubtedly helped by the efficiency of the synchromesh mechanism of the four-speed gearbox. Although the times are not as good as are usually returned by a 3-tonner, it should be remembered that this particular version .of the Paravan has been designed essentially for city deliveries and that normal traffic conditions in most British cities hardly permit the use of rapid acceleration, and a high top speed. In any event, the payload of such a vehicle is constantly decreasing, thus the liveliness would increase towards the end of the round.

Smoothness of engine and transmission during the direct drive acceleration runs was noteworthy, and, indeed, the effectiveness of the engine mountings was marked throughout the whole speed range of the unit, particularly at idling speed. Propeller-shaft smoothness has been assured by the use of a Layrub joint immediately behind the gearbox.

For the first gradient test, the van was taken out to Frith Hill Road, Godalming, where the gradient meter gave a maximum reading of 1 in 9. On this slope the van was stopped and held quite easily on the hand brake, following which a smooth bottom-gear restart was made at about half throttle opening.

We then drove round the Godalming area in search of a steeper gradient and eventually found one measuring 1 in 43, this being Grove Road. The slope was approached from the top, and half-way down the vehicle was stopped, where the hand brake proved its effectiveness once more. The restart in reverse almost succeeded, but as soon as the clutch was fully engaged, the engine speed dropped and the unit stalled.

Because reverse ratio is lower than that of first, there was no point in attempting a restart facing up the slope, but it is apparent that forward restarts on gradients of up to 1 in 5 should not present too much difficulty to the Paravan, and this is as steep a gradient as is likely to be attempted by most parcels vans under normal conditions with a full load.

With a fuel test tank attached, fuel-consumption figures were obtained over a six-mile undulating circuit of the cl4 London Road. Three runs were made with the full load, and these were repeated with 13 tons of the payload removed. The figures obtained show attractive economy for a vehicle of its type, economy which is further enhanced by the generally accepted longer life of an oil engine over that of a petrol engine.

Allowing for the fact that a vehicle of this type would rarely carry more than 3 tons and that at the end of its day's run the payload would have been reduced to nothing, it is reasonable to suppose that the Paravan will return an overall average fuel-consumption figure of between 18 and 19 m.p.g. under normal city-service conditions.

One of the more remarkable things about the Paravan is that, despite the use of conventional single-rate semielliptic springs at both axles, without dampers, the suspension is of a very high standard under all conditions, which all goes to show that the simplest layout can often be the best if properly applied.

This smooth ride is of importance not only to the driver but also to customers, as often the parcels carried in a vehicle of this type can be quite fragile and therefore liable to breakage over bad surfaces. This is not likely to happen with the Paravan, however, because even when driven fast over cobbles, no harsh shocks were felt. Wear and tear on the body will be reduced also.

The Paravan handles well and the steering is comfortably light, with just sufficient castor action to be of assistance when cornering quickly. The van corners well and does not seem to roll unduly. The brakes are pleasant to use and gear changing is good, partly because of the small travel of the short lever. This lever, like that of the hand brake, lies below the level of the seat cushion so that it does not obstruct access to the driving seat from either side of the vehicle.

Although the engine is directly alongside the : driver and covered by a simple two-piece metal cowl, its noise isby no means overpowering and its closeness to the driver is more than compensated for by the thigh degree of accessibiTity afforded with the two panels removed.

A slight point of criticism about the Dennis body concerns the heaviness of the four-piece up-and-over corner door, which is not counterbalanced in any way. The spring-loaded rollers add to the friction, with the result that a fair amount of manual effort is required to raise the door, which suggests that most drivers will prefer to operate with the door left open.

The door can be clipped in this raised position by i simple

• plunger-type catch, but this acts on a rounded snake., with the result that a sudden jerk on the door can over-ride the spring action of the catch and the door can fall with alarm. ing speed..

, In other respects, the body reaches a high standard and I particularly useful is the provision' of side windows to the rear of the driving-seat line, these giving vision usually

denied to van drivers and making-for increased safety particularly at Y-junctions.

The Paravan tested had a body floor height of 3 ft. 6 in., this having been adopted as almost universal in this country for the normal loading-dock height, but for specialized duties a floor line of little more than 2 ft. 6 in. can be

achieved, although this necessitates the use-of wheel boxes over the rear wheels. The Paravan chassis is suitable for bodies of up to 600 cu. ft. capacity and there is a maximum legal body space of 16 ft. 7-1 in. behind the engine, allowing a clear 16 ft. interior body length without wheel boxes if the floor height is 3 ft. 6 in.

I was left with no time in which to carry out maintenance tests. Access to the engine, however, as I have already said, is good and there is a trap in the forepart of the body, immediately over the gearbox, which gives good access to the gearbox and which is wide enough to allow the box to be withdrawn and lifted up through it, as might be necessary when changing a clutch plate and so forth. Because of the deep skirt panels, traps are provided to give access to the spare wheel and batteries, and access to theSe is, naturally. enough not as good as were the body side panels to finishat floor level. ,