The Simms Ignition and Lighting Machine.

Page 7

If you've noticed an error in this article please click here to report it so we can fix it.

We have, of course, been aware for a long while that Mr. h. R. Simms has been engaged upon the production of a combined electrical machine which shall serve at the same time to supply the motor with ignition current and the lamps of the vehicle to which it is attached with current for lighting purposes. There is undoubtedly a pronounced boom at the present time in regard to improved lighting facilities or vehicles of all types. We have recently had occasion to draw attention to the improved methods which are now on offer for use in connection with illuminated advertisement signs, as well as with ordinary van and motorbus lighting systems. It was therefore particularly interesting to us to receive an invitation from Mr. Simms to go to his Willesden works one day last week to examine the completed " Seebright" combined magneto and lighting machine, which is the last word in connection with the prolonged and exhaustive experiments which he has been carrying out in regard to such combined plant. The latest machine has not been designed without a very great amount of research and of careful elimination and alteration. A recital of the many unlooked-for phenomena which developed during the course of the experiments would, we fear, only interest the most technically-minded of our readers. It will, on this ochasion, suffice for us, therefore, in presenting this brief account of the constructional particulars of the new apparatus, to record the fact that a very large number of differing models has been constructed in the Willesden shops before the present " Seebright " was evolved.

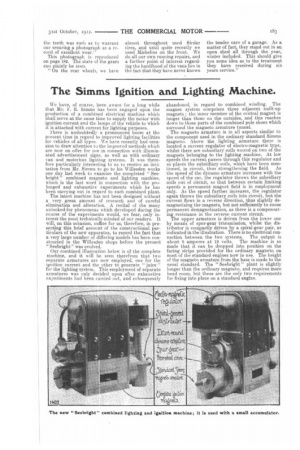

Our combined illustration below is of the complete machine, and it will be seen therefrom that two separate armatures are now employed, one for the ignition current and the other to generate " juice " for the lighting system. This employment of separate armatures was only decided upon after exhaustive experiments had been carried out, and subsequently

abandoned, in regard to combined .winding. The magnet system comprises three adjacent built-up magnets ; the inner member of the central magnet is longer than those on the outsides, and this reaches down to those parts of the combined pole shoes which surround the magneto armature tunnel.

The nutgneto armature is in all aspects similar to the component used in the ordinary standard Simms magneto. Above the lighting armature there is located a current regulator of electro-magnetic type, whilst there are subsidiary coils wound on two of the magnets belonging to the lighting machine. At low epeeds the current passes through this regulator and so places the subsidiary coils, which have been men

tioned, in circuit, thus strengthening the field. As the speed of the dynamo armature increases 'with the speed of the car, the regulator throws the subsidiary coils out of cirtuit, so that between certain limiting speeds a permanent magnet field is in employment only. As the speed further increases, the regulator again throws the subsidiary coils into circuit, but the current flows in a, reverse direction, thus slightly demagnetizing the magnets! but not sufficiently to cause permanent demagnetization, as there is a compensating resistance in the reverse current circuit. The upper armature is driven from the lower one by means of spur-gear transmission, whilst the distributor is compactly driven by a spiral-gear pair, as indicated in the illustration. There is no electrical connection between the two systems. The output is about 8 amperes at 12 volts, The machine is so made that it can be dropped into position on the facing strips provided for the ordinary magneto on. most of the standard engines now in use. The height of the magneto armature from the base is made to the usual standard. The " Seebright " plant. is slightly longer than the ordinary magneto, and requires more head room, but these are the only two requirements For fixing into place on a standard engine.