From Drivers and Mechanics.

Page 18

Page 19

If you've noticed an error in this article please click here to report it so we can fix it.

TEN SHILLINGS WEEKLY is paid for the best communication received, and one penny a line of ten words for anything else published, with an allowance for photographs.

Workshop tips and smart rePairs ; long and successful runs; interesting photographs ; all are suitable subjects, We will knock your letters into shape and will re are sketches, where necessary, before publication. The absence of a sketch does not disqualify for a prize. When writing, use one side of the Paper only and mention your employer's name as a guarantee of bona fides. Neither your own nor your employer's name will be disclosed. Payment will be made immediately after publication. Address your letters to The Editor, THR COMMERCIAL MOTOR, 7-15, Rosebery

Avenue, London, E.C.

Annual Bonuses are given to the most successful contributors.

Different Re pairb L1151] " A.H.E." (Islington) writes : —" Perhaps the following hints may be of use to some of my fellow

drivers. Several of the mechanics at the garage where I am employed have had trouble with the throttle-rods of their engines breaking. To effect a repair I have adopted the following method, in which a few feet of wire and asmall sheet of tin form the most important materials. A notch is filed around the rod, about 1 in. from the fracture, as shown in the sketch. The tin is then twice bent round about the rod, so as to make up a, fairly strong tube. The wire is next wound round the notch at both ends, and, when all is tightened up with a pair of pliers and a little solder, a joint strong enough to take the wagon home is made.

" A driver came into our place the other day, and showed me a spanner which he had made out of an

old Valve. It. had the stem flattened over and a squared notch cut into it, as shown in the sketch, and it had been hardened afterwards. I think this is a very handy way of using up old valves.

"The sketch of the petrol gauge which I forward will, I am sure, be of interest. It consists of a piece of tube about twice the depth of the petrol tank, with a slot cut down one side. The float is made of a piece of cork about. 1 in. in diameter, and it is fitted with a length of wire of about 14 or 18 gauge. This must not be too heavy, or the cork will sink. The wire is bent over to show the position of the float, and the tube marked off."

A Risky Repair to a "Duff. Shaft."

[1152] " R.T." (Andover) writes :--" Owing to a worn ball-race on a live-axle shaft of my van suddenly collapsing, a, fairly deep groove was made at the point where the race fitted the shaft. A new part was procured, but so bad was the condition of the axle that a renewal could not be effected right away. To turn up a new shaft involved too great a delay, so the following method was adopted as being an improvement over the insertion of packing, it was also quicker. "First the worn part of the shaft was turned smooth, and a piece of mild steel was bored out a little smaller than the diameter of the turned part, and made up into a split collar to fit over the shaft at the turned part. This collar was held in position by means of set screws, or, alternatively, it could be secured by rivets going right through. It was then turned down in the lathe, so that the ball-race could be gently driven on. The whole shaft was ready to be re-fitted in the axle-ease in three-quarters of an hour. I do not believe that this is the best repair possible in such a cage, as by this means the shaft is weakened considerably. It was the lack of time that made the job of value."

A Sheet-iron Head-lamp Bracket.

[1153] " J.C.B." (Dartford) writes : —"I send you a sketch and particulars [We have had this re-drawn.ED.] of a simple, but strong, lamp bracket made up from a piece of iron plate. "I experienced considerable trouble with the heavy

headlight that was mounted on the top of the dashboard of the four-ton lorry which I drive. The lamp itself was very convenient, as I could turn the light on to the ground without trouble when confronting horses and other obstacles in dark narrow lanes, but the vibration was very great, and owing to its weight it broke all the usual stock-sized brackets. After a little time in service, all the standard brackets obtainable broke off short, and, on one occasion, considerable damage was done to the lamp. "In order to overcome the trouble, I obtained a piece of i-in. iron plate, and sheared it. out to the pattern shown in the sketch. After drilling the necessary holes for bolting it to the dashboard and lamp, it was an easy matter to heat it up in the fire and shape it as shown.

"A bracket made in this way has now been in use for many months and has withstood a great amount of heavy usage. The reason why it stands up to the work, I think, is that it is rather springy and so is able to withstand violent vibration," A Sparking Plug Repair.

[1154] " S.S." (Dartford) writes :—" I should like to give your readers particulars of a little repair which I effected to a sparking plug. I had to take one of our four-ton petrol vans to London, and when at, Borstall Heath, one of the Invincible ' sparking plugs blew out, the electrodes and the porcelain came away from the iron shell, and, of course, all the compression in that particular cylinder was lost. The row when the engine was running was terrific, and as I was stranded and could not get another plug within three or four miles, I had to think of some dodge to get me out of the trouble. In the tool kit I found a brass cheese-headed screw. I placed this inside the shell, with a copper and asbestos washer on it, and when I tightened down the screw bush I found that quite a good joint was made. Anyhow, it was good enough to allow the wagon to run home. T might inform you that the van was fitted with eight sparking plugs, as it had coil ignition as well as magneto, so that it was not a matter of importance that the sparking plug was out of order so long as the leakage on compression was remedied."

Testing Cylinders with Petrol.

[1155] " A.P." (Axbridge) writes :—" To test for small cracks in the water-jackets, the water-pipes should be dismantled and the plugs screwed in. A set of special plugs with a thread at one end made to screw into the cylinder, and having a nipple on the other end, screwed to take a motor tire pumn, should then be made. The water-jacket should be filled with petrol, and ,a pressure of 100 lb. obtained in the jackets by the pump. Should there be any small cracks, the pressure will force the petrol out." Chains in Winter Weather.

[11561 " AL." (Mile End) writes :—'• I am sure that the following will be a very useful tip to many drivers now that the heavy weather is coming on, and the roads will be muddy and wet. Last winter I had a lot of trouble with the chains on my petrol van, and so I got two old petrol tins and fixed them over the chains, one on each side of the chassis. Ats the bottom of the cans I sweated tubes, fitted with a tap, which was of sufficient diameter to allow thick oil to flow through. All that I have to do is to turn on the taps according to the amount of oil required, and to

see that the cans are filled with oil. I found that this little dodge saved me a great amount of trouble last winter, and it has also been useful through all this present wet summer that we have had. " A little time ago I came across a fellow driver who was held up on the road owing to a broken exhaust valve. This was badly burnt, and it had broken off about 1 in. from the head of the valve. I cut off a length of the valve spring equal to the distance between the valve head and the valve cap. I then fitted the washer to the head of the valve, and by making a hole in the washer, just where the stem goes through, and fitting the screw head on the top of the valve, the spring was held in position at the bottom and the recess in the valve cap held the top. The stem was allowed to slide freely in the guide. This temporary repair was sufficient to take the van to a repair shop two miles away. where a. new valve was fitted."

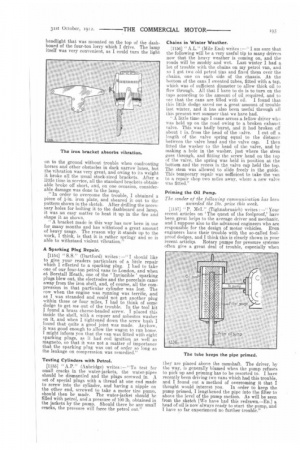

Priming the Oil Pump.

The sender of the following communication has been awarded the 10s. prize this week.

[1157] "P. Mc!." (Tighnabrunich) writes :—" Your recent articles on The quest of the foolproof,' have been great helps to the average driver and mechanic, and I suppose also to the advanced engineers who are responsible for the design of motor vehicles. Even engineers have their trouble with the so-called foolproof dodges, and I think this is clearly shown in your recent articles. Rotary pumps for pressure systems often give a great deal of trouble, especially when they are placed above the camshaft, The driver, by the way, is generally blamed when the pump refuses to pick up and priming has to be resorted to. I have recently been driving two vans which had this trouble, and I found out a method of overcoming it that I thought would interest you. In order to keep the pump primed, I lengthened the pipe into the filter to above the level of the pump suction. As will be seen from the sketch [We have had this redrawn.—En.1 a head of oil is now always ready to start the pump, and 1 have so far experienced no further trouble. '