Picking up the pieces

Page 43

Page 44

Page 45

If you've noticed an error in this article please click here to report it so we can fix it.

and using them to improve truck safety

by CM reporter

IF a truck crashes within 65 miles of Gothenburg, Sweden, the police or emergency services quickly flash a message to the accident investigation branch of AB Volvo, and one of three specialists who share a 24-hour watch will hurry to the scene in his RTequipped estate car.

For the past four years this Volvo Crash Commission has been attending commercial vehicle accidents to make an on-the-spot assessment of cause and effect, subsequently following up the medical history of anyone injured and making a detailed examination of the vehicle or vehicles involved.

As well as attending crashes of any make of truck in this fairly large — but thinly populated local area, the Volvo crash team investigates every truck driver fatality anywhere in Sweden — of which there are about 10, involving heavy trucks, each year. In all, the team makes in-depth reports on 100 to 120 accidents a year.

The group was launched as an o. shoot of the Volvo product plannii department, and its principal object is help designers to "design in" safety new vehicles and to eliminate any pote tially dangerous features of existi vehicles.

One of the important aspects of t accident investigations is to see wf parts or characteristics of a heavy tru tally caused the damage to the other icle or object or the injuries to pie. This has already contributed to design and prototype trials of dent-prevention and injury-reducequipment -such as the cyclist rd rails fitted to the G89 24-metre ble-bottom outfit which CM tried year (CM September 21) and which ne of the key pieces of hardware in vo's "SET" system; S for safety, E !conomy and T for Traffic environt.

jell Hogstrom told me that so far as ould establish, this was the only dent investigation group operated a vehicle maker anywhere in the Id, and the only one of any type :h was devoted solely to commervehicle crash research. His team es its findings on roll-over accis (of which it has made a study) to tin's Transport and Road Research Dratory.

jell Hogstrom himself is an exirer of trucks and an ex-truck f.tctor for the Ministry. Another iber of the team is from the Volvo ;n office and they can call on a 'o-employed doctor when followup personal injuries or causes of death.

Some of their recommendations have already found their way into production vehicles in specific ways — for example, the "ignition" key on the F86 has been moved from a position in line with the driver's knee, the steering column has been shrouded and the cab has seat belt mountings built in.

Recessed switches

On the new normal-control N series, all the switches are recessed and have an action designed to prevent inadvertent wrong operation. Also, bodybuilder Forss Parator is now offering in Sweden a Volvo-inspired trailer headboard reinforced to take far greater braking or impact loads than normally accepted designs.

On a more general level, the Crash Commission's findings have supported the US-canvassed view that truck drivers would be safer wearing seat belts: that stay-shut cab doors are a vital part of crash survival for lorry crews — assuming strongly built cabs, such as Swedish safety laws demand: that too many drivers are killed or injured by being thrown out of the vehicle: that powerful, controllable braking is still one of the best ways of avoiding severe damage and injury: and that if cost were no object, safer commercial vehicles could be put on the market, because the technology is already developed and the hardware available.

Kjell Hogstrom emphasized that having safety locks which kept cab doors shut was important from two viewpoints: it preserved the "box" strength of the cab structure and thus protected the occupants, and it helped prevent them being ejected into the road. Of the 10 heavy-truck drivers killed in Sweden in 1972, five had been pitched out of the cab. And even with safety-locked doors, a driver can still be thrown out through the screen unless he is held in by a seat belt. Which in turn leads to the need for strong headboards to help restrain the load.

Volvo's considerable expenditure on accident investigation and safety research is being made against the background of safety legislation which is now moving particularly quickly in Sweden. From January 1 1973, all new :tommercial vehicles over 3.5 tonnes gvw or gcw have had to have rear under-run bumpers of approved design (Sweden has type approval for vehicles). From last year, too, all new and existing vehicles over bm long have had to have side marker lights of at least 4cp, in specified combinations.

Driver licensing

Since August 1973, headlamp wipers have been compulsory on new vehicles — a provision of particular relevance in Sweden's climate and with her fairly high proportion of unmade secondary roads. And last year an entirely new driver licensing system came into force, including an onerous hgv licensing scheme.

Under this hgv licensing system there is a "grandfather" clause exempting from test those who have a car licence and have had 12 months' experience of heavy truck driving. But others, and all newcomers, will have to undergo about three weeks intensive training to get a bus driving licence and 10 to 13 weeks to get a heavy truck driving licence.

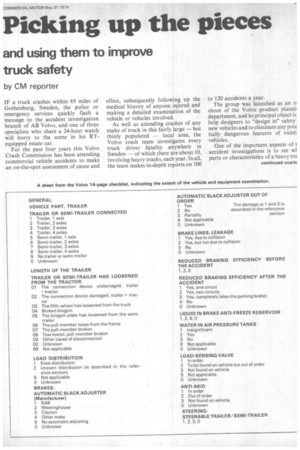

In the four years it has been running, Volvo's Crash Commission has developed considerable expertise and sophistication. After making an initial assessment of the accident, the investigator examines the details against a 14foolscap-page checklist dealing with every imaginable feature — the characteristics, working hours and qualifications of the driver(s), the post-crash condition of the cab, the major components, the tyres, windows, seats, the state of the road, the nature and cause of the injuries. — it runs to hundreds of questions and a series of diagrams on which structural deformations and so on are marked in coded form.

This record sheet, as well as forming the basis for a detailed written report with conclusions, is coded as the basis of a computer input, and Volvo now runs computer assessments in order to throw up statistically significant crash factors very rapidly.

It is an interesting comment on the growing international flavour of road transport to discover that the Swedish authorities, and Volvo's engineers, are looking at the crash resistance of cab front panels and front corners — aspects which the UK and the EEC are also investigating with legislation in mind because of the incidence of driver leg injuries in accidents on motorways and other main roads.

Sweden's present cab strength tests, which have set her requirements apart from other countries', sprang from the cab crushing and overturning accidents which the topography, the climate and the types of industry — especially mineral excavation and lumberjacking —made more prevalent.