Demountable Bodies Aid B.R. Parcels Distribution

Page 57

If you've noticed an error in this article please click here to report it so we can fix it.

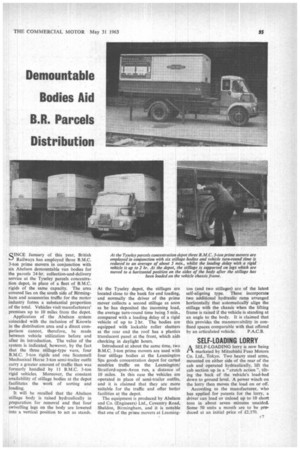

QINCE January of this year, British Railways has employed three B.M.C. 3-ton prime movers in conjunction with six Abelson dernountable van bodies for the parcels 24-hr. collection-and-delivery service at the Tyseley parcels concentration depot, in place of a fleet of B.M.C. rigids of the same capacity_ The area covered lies on the south side of Birmingham and accessories traffic for the motor industry forms a substantial proportion of the total. Vehicles visit'manufacturers' premises up to 10 miles from the depot.

Application of the Abelson system coincided with the inclusion of Knowle in the distribution area and a direct cornparison cannot, therefore, be made between vehicle utilization before and after its introduction. The value of the system is indicated, however, by the fact that the three stillage-type vans, four B.M.C. 3-ton rigids and one Scammell Mechanical Horse 3-ton semi-trailer outfit carry a greater amount of traffic than was formerly handled by 11 B.M.C. 3-ton rigid vehicles. Moreover, the constant availability of stillage bodies at the depot facilitates the work of sorting and loading.

It will be recalled that the Abelson stillage body is raised hydraulically in preparation for removal and that four swivelling legs on the body are lowered into a vertical position to act as stands.

At the Tyseley depot, the stilIages are located close to the bank for end loading, and normally the driver of the prime mover collects a second stillage as soon as he has deposited the incoming load, the average turn-round time being 5 min., compared with a loading delay of a rigid vehicle of up to 2 hr. The bodies are equipped with lockable roller shutters at the rear and the roof has a plastics translucent panel at the front, which aids checking in daylight hours.

Introduced at about the same time, two B.M.C. 3-ton prime movers are used with four stillage bodies at the Leamington Spa goods concentration depot for carted sundries traffic on the Leamington/ Stratford-upon-Avon run, a distance of 10 miles. In this case the vehicles are operated in place of semi-trailer outfits, and it is claimed that they are more suitable for the traffic and offer better facilities at the depot.

The equipment is produced by Abelson and Co. (Engineers) Ltd., Coventry Road, Sheldon, Birmingham, and it is notable that one of the prime movers at Learning

ton (and two stillages) are of the latest self-aligning type. These incorporate two additional hydraulic rams arranged horizontally that automatically align the stillage with the chassis when the lifting frame is raised if the vehicle is standing at an angle to the body. It is claimed that this provides the manceuvrability in confined spaces comparable with that offered by an articulated vehicle. P.A.C.B.

SELF-LOADING LORRY

ASELF-LOAD1NG lorry is now being marketed by Mitsubishi Fuso Motors Co. Ltd., Tokyo. Two heavy steel arms, mounted on either side of the rear of the cab and operated hydraulically, lift the cab section up in a "crutch action ", tilting the back of the vehicle's load-bed down to ground level. A power winch on the lorry then moves the load on or off.

According to the manufacturer, who has applied for patents for the lorry, a driver can load or unload up to 10 short tons in about seven minutes unaided. Some 50 units a month are to be produced at an initial price of £2,370.