Self-contained Battery-electric Conversion

Page 114

If you've noticed an error in this article please click here to report it so we can fix it.

A Résumé of Patent Specifications that Have Recently Been Published

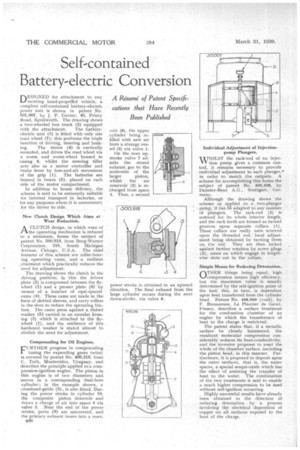

DESIGNED for attachment to any existing hand-propelied vehicle, a complete self-contained battery-electric power unit is shown in patent No. 501,007, by J. P. Garner, 45, Priory Road, Kpnilworth, The drawing shows a two-wheeled box truck (2) equipped with the attachment. The batteryelectric unit (3) is fitted with only one road wheel (7); this performs the triple Junction of driving, steering and brak

ing. The motor (4) is vertically mounted, and drives the road wheel via a worm and worm-wheel housed in casing 6, whilst the steering tiller acts also as a motor controller and brake lever by fore-and-aft movement of the grip (1). The batteries are housed in boxes (5), placed on each side of the motor compartment.

In addition to house delivery, the scheme is said to be eminently suitable for internal transport in factories, or for any purposes where it is unnecessary for the driver to ride..

New Clutch Design Which Aims at • Wear Reduction.

ACLUTCH design, in which wear of

• he operating mechanism is reduced to a minimum, forms the subject of patent No. 500,918, from Borg-Warner Corporation, 310, South Michigan Avenue, Chicago, U.S.A. The chief features of this scheme are roller-bearing operating cams, and a resilient abutment which practically reduces the need for adjustment.

The drawing shows the clutch in the driving position; in this the driven plate (2) is compressed between the flywheel (1) and a presser plate (6) by means of a number of equi-spaced cams (4). These cams are made in the form of slotted sleeves, and carry rollers in the slots to reduce the operating friction. The cams press against a dished washer (5) carried in an annular housing (3) which is attached to the flywheel (1) , and the resilience of this hardened washer is stated almost to abolish the need for adjustment.

Compounding for Oil Engines.

FCRTHER progress in compounding 1 (using the expanding gases twice) is covered by patent No. 499,216, from C. Toth, Montevideo, Uruguay, and describes the principle applied to a compression-ignition engine. The piston in this engine is of two diameters and moves in a corresponding dual-bore cylinder ; in the example shown, a crosshead-guide (5), is also fitted. During the power stroke in cylinder 10, the composite piston descends and draws a charge of air into space 4 via valve 3. Near the end of the power stroke, ports (9) are uncovered, and the primary exhaust issues into a reser

1336 voir (8), the upper cylinder being. refilled with new air from a storage vessel (2) via valve 1.

On the next upstroke valve 7 admits the stored exhaust gas to the underside of the larger piston, whilst the air reservoir (2) is recharged from space 4. Thus, a second

Individual Adjustment of Injectionpump Plungers.

WHILST the rack-rod of an injecV V tion pump gives a common control, it remains necessary to provide individual adjustment to each plunger,' in order to match the outputs. A scheme for accomplishing this forms the subject of patent No. 500,508, by Daimler-Benz A.G., Stuttgart, Germany.

Although the drawing shows the scheme as .applied .to a two-plunger pump, it can lib adapted to any number of plungers. The rack-rod (2) is screwed for its whole interior length, and the rack teeth are formed as turned grooves upon separate collars (1). These collars are really nuts screwed upon the threaded rod, local adjustment being obtained by turning them on the rod. They are then • locked against further rotation by screw plugs (3), noses on which engage in lengthwise slots cut in the collars.

Simple Means for Reducing Detonation.

0,,THER things being equal, high L./compression means high efficiency, but the maximum value is usually determined by the self-ignition point of the fuel; this, in turn, is dependent upon heat transferred from the cylinder head. 'Patent No. 498,909 (void), by F. Broussouse, Le Plantier de Garat, France, describes a surface treatment for the combustion chamber of an engine by which the transference of heat to the charge is restricted.

The patent states that, if a metallic surface be closely hammered, the resultant molecular compression considerably reduces its heat-conductivity, and the inventor proposes to treat the whole of the chamber surface, including the piston head, in this manner. Furthermore, it is proposed to deposit upon the outer surfaces, that is, the water spaces, a special sesqui-oxide which has the effect of assisting the transfer of beat to the water. The combination of the two treatments is said to enable a much higher compression to be used without sell-ignition occurring.

Highly successful results have already been obtained in the direction of reducing detonation by a process involving the electrical deposition of copper on all surfaces exposed to the heat of the charge.