Combustion Chamber Design for Oil Engines

Page 60

If you've noticed an error in this article please click here to report it so we can fix it.

A Resume of Recently Published Patent Specifications

INpatent No. 388,262, A. W. Wiseman, Ltd., 89, Glover Street, Birmingham, describes a combustion chamber for oil engines in which a projection from the top of the piston enters the neck of the chamber, leaving only a limited space for air to enter during the last stage of the compression stroke.

The compressed air enters in the form of a ribbon and at a tangent, so that a rotary movement is imparted to it. The chamber is cylindrical, and valves with horizontal stems are provided.

Another Epicyclic Gear.

THE epicyclic gear described in

patent No. 388,243, by L. K. Cheswright, 85, 31,orningside Avenue, Village of Swansea, Ontario, Canada, is on somewhat conventional lines, except that the usual external brake band is replaced with a ring which, by axial movement, is brought in contact with a stationary ring fixed to some part of the frame, Two integral planetary gears engage with two sun wheels mounted on the driving shaft (1) and the driven shaft (2) in a known manner. An outer ring is non-rotating and is supported by toggles which allow it to act to hold another ring (15) in one direction, the toggles relieving the resistance when the second ring (15) rotates in a reverse direction. The friction between these two parts provides the means for holding the carrier, whilst a cone clutch provides the direct drive by the parts 8 and 11, both being operated by the collar (21), axial motions of which, to the right, releases the clutch.

A Novel Starter Pinion Arrangement.

IN the arrangement of starter pinion described in patent No. 388,253, by the Eclipse Machine Co., New York, two interlocking helical springs take the place of the usual screw. One end of each spring is anchored to its member, so that the same effect is produced as when a screw is used, inertia being relied upon to cause the pinion to advance, and a further spring (29) returning it. The specification does not make clear in what way this arrangement is considered as an improvement on the usual screw.

A Rubber-bushed Universal Joint.

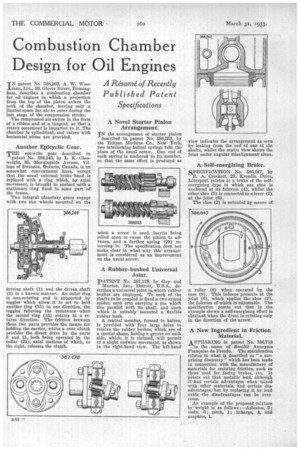

pATENT No. 387,178, by Guy and Murton, Inc., Detroit, U.S.A., describes a universal joint in which rubber bushes are employed. To each of the shafts to be coupled is fixed a two-armed spider, each arm carrying a pin which lies parallel with its shaft, and upon which is suitably mounted a flexible rubber bush.

A. central member, formed in halves, is provided with four large holes to receive the rubber bushes, which are of a special shape, having a groove on each side, which, it is claimed, will permit of a slight endwise movement, as shown in the right-hand view. The left-hand

view indicates the arrangement as seen by looking from the end of one of the shafts, whilst the centre view shows the joint under angular misalignment alone.

ASelf-energizingBrake,

SPECIFICATION No. 386,647, by R. A. Crockett, 29, Kremlin Drive, Liverpool, relates to a brake of the selfenergizing type in which one shoe is anchored at its fulcrum (4), whilst the other shoe (3) is connected to a lever (7), at the joint (6).

The shoe (2) is actuated by means of

a roller (8) when operated by the cam (9). This induces pressure at the joint (6), which applies the shoe (3), the fulcrum of which is adjustable. The specification points out that in the example shown a self-energizing effect is obtained when the drum is rotating only in the direction of the arrow.

A New Ingredient in Friction Material.

APPEARING in patent No. 386,718

is the name of Societe Anonyme Framnise du Ferodo. The specification relates to what is described as "a surprising discovery" which has been made in connection with the manufacture of materials for resisting friction, such as those used for facing brakes, etc. It points out that metallic lead, although it had certain advantages when mixed with other materials, had certain disadvantages, but by replacing it by lead oxide -the disadv.antages can be over come.

An example of the proposed mixture by weight is as follows :—Asbestos, 9; resin, 5; pitch, 1; litharge, 4, and graphite, 1.