Economical Scarab with

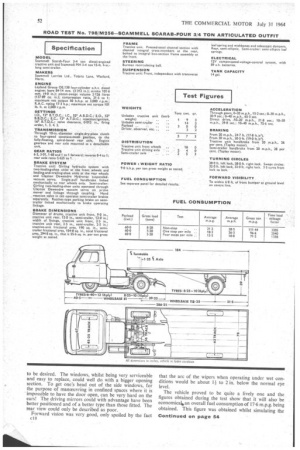

Page 52

Page 53

Page 54

Page 56

If you've noticed an error in this article please click here to report it so we can fix it.

cellent Brakes

ROAD TEST: Scammell Scarab 3 4-ton articulated outfit

By R. D. CATER

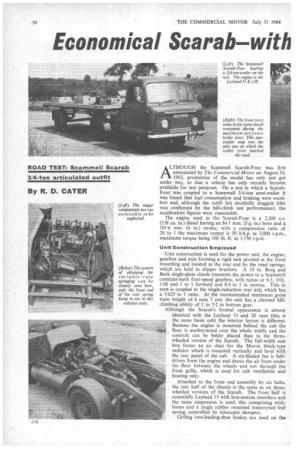

ALTHOUGH the Scammell Scarab-Four was first announced by The Commercial Motor on August 24, 1962, production of the model has only just got under way, so that a vehicle has only recently become available for test purposes. On a test in which a ScarabFour was coupled to a Scammell 3/4-ton semi-trailer it was found that fuel consumption and braking were excellent and, although the outfit felt decidedly sluggish (this was confirmed by the hill-climb test performance), the acceleration figures were reasonable.

The engine used in the Scarab-Four is a 2,260 c.c. (138 cu. in.) diesel having an 84.1 mm. (3-Ain.) bore and a 101.6 mm. (4 in.) stroke; with a compression ratio of 20 to I the maximum output is 50 b.h.p. at 3,000 r.p.m., maximum torque being 100 lb. ft: at 1,750 r.p.m.

Unit Construction Employed Unit construction is used for the power unit, the engine, gearbox and axle forming a rigid unit pivoted at the front mounting and located at the rear end by the road springs, which are held in slipper brackets. A 10 in. Borg and Beck single-plate clutch transmits the power to a Scammell constant-mesh four-speed gearbox, with ratios or 6-3, 3-01, 1.68 and 1 to 1 forward and 8.4 to 1 in reverse. This in turn is coupled to the single-reduction rear axle which has a 5.625 to I ratio. At the recommended maximum gross train weight of 6 tons 7 cwt. the unit has a claimed hillclimbing ability of 1 in 5-2 in bottom gear.

Although the Scarab's -frontal appearance is almost identical with the Leyland 15 and 20 vans (this is the same basic cab) the interior layout is different. Because the engine is mounted behind the cab the floor is unobstructed over the whole width, and the controls can be better placed than in the threewheeled version of the Scarab. The full-width seat box forms an air duct for the Morris block-type radiator which is mounted vertically and level with the rear panel of the cab. A six-bladed fan is beltdriven from the engine and draws the air from under the floor between the wheels and not through the front grille, which is used for cab ventilation and heating only.

Attached to the front end assembly by six bolts, the rear half of the chassis is the same as on threewheeled versions of the Scarab. The front half is essentially Leyland 15 with box-section members and the same suspension is used, this comprising wishbones and a single rubber mounted transversed leaf spring, controlled by telescopic dampers.

Girling two-leading-shoe brakes are used on the front wheels, dimensions being 9 in. diameter by 24 in. wide. The rear brakes have leading-and-trailing shoes measuring 12 in. by 24 in. Both are hydraulically operated through a Clayton-Dewandre Hydrovac suspended-vacuum servo. Braking on the trailer also is by 12 in.-diameter, 21-in.-wide Girling brakes but these are cable operated through the automatic coupling by a Clayton-Dewandre vacuum servo. This can be separately applied by a hand reactor valve fitted at the offside of the driving seat.

The Handbrake The tractive unit handbrake is operated by a single-pull lever with a press-button release and •is mounted on the nearside of the driving seat; it applies the rear wheel brakes only. With a total frictional area of 190 sq. in., the ScarabFour is better equipped than the three-wheeled version by 86 sq. in.

The 12 V. electrical system is powered by two 6 V. batteries, one being mounted behind each seat. Flashers are a standard fitting.,

The test took place on and around A6 in the area of Barton in the Clay, Bedfordshire. The first thing that struck me, literally, was the top of the cab. The top sill of the door comes level with the top of the head of anyone standing around 5 ft. 10 in. and this means that the driver must duck his head when getting in; once in, the seating position is very comfortable, but the clearance between the lower front of the seat and the pedals is far too small to allow proper application of the brakes, except when the seat is in the fully back position.

The low top sill of the doors creates another snag once the driver is in the seat, as it restricts very badly the vision to the side in a horizontal direction, it being about 24 to 3 in. below eye level.

On the day of the test the ambient temperature was 26°C (78°F) and theventilation of the cab left something

to be desired. The windows, whilst being very serviceable and easy to replace, could well do with a bigger opening section. To get one's head out of the side windows, for the purpose of manceuvring in confined spaces where it is impossible to have the door open, can be very hard on the ears! The driving mirrors could with advantage have been better positioned and of a better type than those fitted. The rear view could only be described as poor.

Forward vision was very good, only spoiled by the fact c18 that the arc of the wipers when operating under wet conditions would be about 11 to 2 in. below the normal eye level.

The vehicle proved to be quite a lively one and the figures obtained during the test show that it will also be economicalean overall fuel consumption of 17.6 m.p.g. being obtained. This figure was obtained whilst simulating the

Continued on page 54

sort of traffic conditions that one would expect this type of machine to operate under.

The only other thing that spoiled the comfort of this vehicle was the noise, which was of a very high level indeed—very much higher, I would say, than many maximum-capacity machines that I have driven. This was a pity, because most of this appeared to emanate from engine vibration rather than engine noise, this vibration being transmitted through the cab panels in the form of a harsh, nerve-shattering rumble. I certainly would not like to drive the machine I tested for the distances involved in the longer operations envisaged by the makers. A journey of, say, 50 miles each way would really represent enough for the crew.

The test vehicle had only completed just over 200 miles, and most of the controls were on the stiff side, particularly the gear lever which at first proved difficult to operate. This, however, proved to be a case of getting used to it, and as the day went on the difficulty disappeared.

The tractive unit was coupled to a Scammell single-axle 3/4 ton semi-trailer through the well-known Scamtnell MH automatic coupling and loaded as it was with 3 tons of test weights gave an extremely comfortable ride, whilst the steering and handling qualities were good at both high and low speeds. The unit also proved to be very easy to reverse on both short and long turns with no problems arising on either lock, and was capable of being reversed for almost any distance in a straight line without any tendency to run off the line chosen.

The cruising speed of the outfit proved to be anywhere between 35 and 40 m.p.h. and a top speed of 44 m.p.h. was obtained on the Ml; this, however, was unbearable, with everything vibrating fit to burst.

The braking figures were good. Several stops were made from 20 and 30 m.p.h. and the respective figures were 24 ft. 6 in. (75 per cent on the Tapley meter) and 50 ft. 10-5 in. (81 per cent).

Most of the braking effort seemed to be on the steering axle, both the front wheels locking on every stop. The driving axle and the trailer axle only succeeded in marking the road very lightly and I would think that, given a bit more braking effort here, better figures would be obtained. On every one of the test stops, the front of the tractive unit started to slide away down the camber of the road.

The handbrake also proved quite good. The tractive unit gave 24 per cent from 20 m.p.h., and the trailer hand control gave 27 per cent. These same units when tested for holding on the I in 6.5 gradient of Bison Hill showed up in just the opposite Way, the tractive unit brake just holding and the trailer brake failing to do so. The effort required to apply the tractive unit handbrake was considerable, and

I felt that the lever would have been better mounted lower (-20

down so that more purchase could have been applied. This only proved to be the case when the 'holding tests were carried out, as under normal circumstances the lever was suitably placed.

Hill climbing tests were carried out on Bison Hill and the Scarab-Four climbed this 'easily with a bit in hand. The 0.75-mile-long hill, which has an average gradient of 1 in 10.5, took 5 minutes 8.5 seconds to climb and the time in the lowest gear, which was first, was 2 minutes 29.4 seconds. On reaching the top of the' hill the engine coolant was checked. This proved to be boiling, and a thermotneter reading of just over 100°C (212°F) was taken. As the ambient temperature was 26°C (79°F) and the starting temperature was 79°C (174°F) the rise in temperature of 21°C (70°F) was perhaps not surprising. The vehicle was easily started from a standstill on the steepest section of the climb in first gear; the starting test in reverse, when facing down the slope, was also easily accomplished and the vehicle only bucked very moderately as the drive was taken up. '

Moving forwards, I had the feeling that the gap between first and second gears was too-wide, because although the engine was revving unnecessarily high in first gear it was impossible to change into second gear without bringing the outfit to a standstill on the hill.

Brake fade tests were carried out by coasting down Bison Hill at an average of 20 m.p.h., checking the speed of the vehicle with the footbrake. On the last section the gradient is not steep enough to keep up the required speed, so this was done by driving in top gear with full throttle applied against the brakes. Total time taken to come down was 2 minutes 42.4 seconds, and the time in top gear was 38.6 seconds. A maximum-pressure stop from 20 m.p.h. produced a Tapley-meter reading of 64 per cent. The reduction of 11 per cent was due to fade at the liners of the driving axle; smoke was pouring from these drums at the end of this test and the unit pulled very hard to the nearside.

The turning circle proved to be 28 ft. both on the leftand right-hand locks, the swept circle proved to be 32 ft. and 31 turns were required to move the steering from one full lock to the other.

From the maintenance point of view I would say that this vehicle has just about everything; the engine is inclined to the offside at an angle of 50° and consequently the fuel pump assembly, filters, dynamo, etc., are very easy to get at. When the bonnet assembly was removed I could see no major component that would present difficulty to the average fitter when maintenance was required. This sort of layout encourages the stitch-in-time to be applied and everyone knows the rest of that proverb.