FACTORS IN FUEL ECONOMY AND CORRECT CARBURATION.

Page 49

Page 50

Page 51

If you've noticed an error in this article please click here to report it so we can fix it.

The Concluding Portion of Our Article Dealing With Petrol Wastage and the Latest Developments in Carburetter Design.

IN the first part of this article, which we published last week, we dealt not so much with actual carburetter design and the various ways in which the different makers have achieved their objects, but with general considerations as to the reasons for excessive consumption of fuel, the rapid wear of carburetters not especially designed for work on commercial vehicles and the mixture requirements at various engine speeds. We do not wish in this, the concluding portion of the article, to repeat the illustrations already given and we, therefore, ask those of our readers who are particularly interested in the subject te refer to those diagrams previously published, where reference is now made to them. The drawings reproduced were of the latest type• S.U. instrument, the Stromberg U-type with pump device for accelerating, the standard vertical type Zenith instrument and the Solex. There were also a half-tone illustration of the Claudel-Hobson, with its special power jet, and two graphs illustrating the action of the main and compensating jets in the Zenith carburetter.

We will deal first with the standard Zenith instrument. It is maintained by the makers, the Zenith Carburetter Co., Ltd., 40-42, Newman Street, London, W.1, that a properly adjusted Zenith instrument will supply a constant mixture of petrol and air at all speeds. The graphs, to which we have already referred and which were taken from an actual vehicle, show that the results in practice approximate very closely. to the theoretical principle of the design.

In making the tests, separate petrol pipes were arranged to supply the main and compensating jets and to each pipe was attached a flowineter. It will be

noted that at 5 m.p.h. the main jet is still inoperative, the compensating jet furnishing the fuel. As the speed increases, the main jet takes up its share of the work and the flow through both rises with the speed up to between 10 m.p.h. and 15 m.p.h. At this point, the atmospheric well over the compensating jet is drained and compensation commences. Thereafter, the amount of petrol flowing through this jet remains practically constant, whilst that from the main jet, on the other hand, shows a steady increase as the speed is raised.

Thus we have, shown graphically, the Zenith principle, which is a combination of two jets, one giving a mixture of increased richness as the engine speed rises and the other one of diminishing strength. It is evident that changes in the sizes of the jets mean only alterations in the degree of variation; in other words, the extent to which each jet affects the resultant mixture and this without in any way affecting the flow characteristics.

One of the charts shows that below 6 m.p.h. the greater part of the fuel is supplied through the compensating jet ; at .Teeds in excess of 16 m.p.h. the main jet supplies most of the fuel and at 40 m.p.h., actually 78 per cent. As regards the best adjustments for the Zenith carburetter, it is difficult to give definite figures in respect of jet sizes. Generally speaking, however, they are those which give the best petrol consumption. It does not always follow that if the jets in a carburetter be reduced in size the petrol consumption will likewise be lessened ; it is quite possible to fit smaller jets in a carburetter, thus making the mixture weaker and yet cause an increase in the consumption as a result of the loss of efficiency. The designers of the Zenith consider that the proper heating of the carburetter or its manifold passages is most important. The employment of inefficient heating systems means that larger jets have to be used, with the result that the petrol consumption rises.

The means for heating recommended by them is a water-jacket around the inlet pipe immediately above the carburetter.

The adjustment of the mixture for slow running plays a particularly important part in the ultimate fuel consumption of a commercial vehicle because this type so often has a considerable amount of idling or running very slowly in traffic, and it is during these periods that most of the work is being done by the slow-running device.

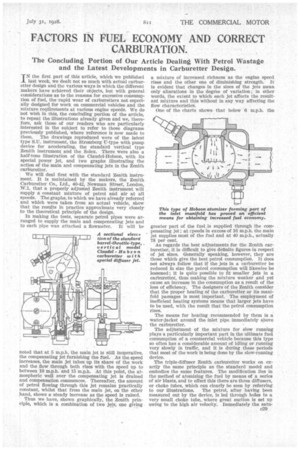

The triple-diffuser Zenith carburetter works on exactly the same principle as the standard model and embodies the same features. The modification lies in the method of atomizing the fuel by means of a series of air blasts, and to effect this there are three diffusers, or choke tubes, which can clearly be seen by referring to our illustrations. The petrol, after having been measured out by the device, is led through holes to a very small choke tube, where great suction is set up owing to the high air velocity. Immediately the satu rated mixture passes out of this choke, it is sucked up by a second stream of air, not moving at such a high speed, but sufficiently fast to complete the process of atomization. The mist thus formed is readily picked up by the remainder of the air and passes through the largest choke at a comparatively low velocity. The three streams of air cause great turbulence, which tends to make the mixture homogeneous.

We have already referred to the Claudel-Hobson carburetter of the power-jet type. This device greatly simplifies carburetter adjustment and tuning as the three functions regarding fuel measurement, i.e., slow running or idling, ordinary running at less than full throttle, and at full throttle, are each mainly in fluenced by a particular jet, so that alterations for any special purpose can be made without affecting other sections of the speed and load range. We need not refer in detail to the special type of diffuser jet employed in the Claudel-Hobson instrument, as this is so well known and has been embodied in designs previous to the power-jet instrument. It is usually found that, when employing this type, slightly more advance can be given to the ignition and, if the utmost economy be required, the diffuser jet should be small enough to give symptoms of weakness until the engine is well warmed up to its work. The main jet should give sufficient petrol for medium acceleration, but be kept small for economy's sake.

Tests made on a Dorman engine, in conjunction with a Fronde dynamometer, are shown in a graph which we reproduce. The curve with the plain dots represents the results obtained with the Claudel-Hobson power-jet device, those with the ringed dots the results 1130 obtained with another make of carburetter, and the shaded portion indicates the saving of petrol effected by employing the Claudel-Hobson. It should be noted that the saving is greatest at an engine speed of 1,000 r.p.m.

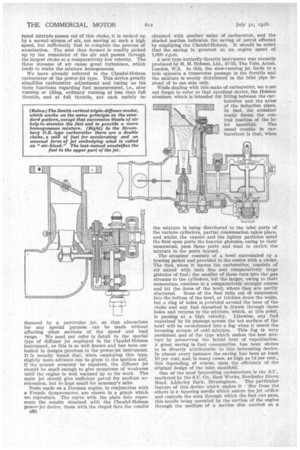

A new type butterfly-throttle instrument was recently produced by H. M. Hobson, Ltd., 47-55, The Vale, Acton, London, W.3. In this, the slow-running jet feeds to a hole opposite a transverse passage in the throttle and the mixture is evenly distributed in the inlet pipe instead of to one side only.

While dealing with this make of carburetter, we must not forget to refer to that excellent device, the Hobson atomizer, which is intended for fitting between the carburetter and the arms of the induction pipes. In fact, the atomizer really forms the central position of the inlet manifold. The usual trouble in carburetters is that, when the mixture is being distributed to the inlet ports of the various cylinders, partial condensation takes place, and whilst the vapour and the lighter particles enter the first open ports the heavier globules, owing to their momentum, pass these ports and tend to enrich the mixture in the ports beyond.

The atomizer consists of a bowl surrounded by a heating jacket and provided in the centre with a choke. The fuel, when it leaves the carburetter, consists of air mixed with both fine and comparatively large globules of fuel; the smaller of these turn into the gas streams to the cylinders, but the larger, owing to their momentum, continue in a comparatively straight course and hit the dome of the bowl, where they are partly shattered. Some of the fuel falls out of suspension into the bottom of the bowl, or trickles down the walls, but a ring of holes, is provided around the base of the choke and any fuel deposited is drawn through these holes and returns to the mixture, which, at this point, is passing at a high velocity. Likewise, any fuel vaporized by its passage across the hot surface of the bowl will be recondensed into a fog when it meets the incoming stream of cold mixture. This fog is very persistent and of the type which makes the best mixture by preserving the latent heat of vaporization. A great saving in fuel consumption has been shown to be directly attributable to this interesting device. In ahnost every instance the saving has been at least 10 per cent. and, in many cases, as high as 14 per cent., this depending, of course, upon the efficiency of the original design of the inlet manifold.

One of the most interesting carburetters is the

marketed by the S.U. Co., East Works, Bordesley Green Road, Adderley Park, Birmingham. The particular feature of this device which makes it r 'ffer from the others is a tapering needle which enters the jet orifice and controls the area through which the fuel can pass, this needle being operated by the suction of the engine through the medium of a suction disc carried on a

piston. The result of this arrangement is that, as regards inixttre curves, it is possible to vary these to any desired point in the speed range, making the mixture either rich or weak there without affecting it at other points, this being achieved by modifying the shape of the needle. Generally speaking, however, a fairly uniform strength of mixture is necessary.

By having the needle too small at the shoulder and too large at the point the mixture will be strong at low speeds and weak at high, but any other combination can be obtained in the same manner. It is also possible, by suddenly enlarging the needle at any point, to cut off the petrol, thus enabling an engine to be governed entirely by the carburetter. For instance, should it be required to make an engine cut off at, say, 2,000 r.p.m. and assuming that at this speed the carburetter piston is at a height of three-quarters of an inch, a blob on the needle at this point will block the jet so soon as it arrives at it and the engine will at once cease to fire until it slows down and the piston drops again, enabling the fuel to pass.

Another interesting instrument is the Stromberg, marketed by Stromberg Motor Devices, Ltd., Milman Street and Cheyne Walk, Chelsea, London S.W.10, and it is notable that the 0X3 model is utilized on Leyland six-cylindered engines. The 0-series is characterized by a double-choke-device (the main jet being located in the centre of a small venturi), a well of fuel for accelerating and what is known as an " air-bleed " economizer. The air-bleed atrangement is a particular feature of the Stromberg instruments. It consists of a passage which allows a small quantity of air to enter the jet below the level of the fuel in it. This reduces the retarding effect usually experienced in lifting liquid above its own level, for the fuel is really in a state of emulsion above the point of air entry.

To permit idling a fuel by-pass is provided, the fuel entering at ft point close to the throttle where, when the throttle is nearly closed, the air velocity is high. The fuel is metered out to the main jet system and the by-pass draws its supply from the main jet, the amount being determined by an adjustable metering device in the by-pass. At very low speeds the mixture is controlled by the idling orifice and at high speeds by the main-jet orifice. Whether the fuel is going through the idling by-pass or through the main jet depends upon Which is experiencing the higher suction.

It is a simple matter to provide an economizer needle

for controlling the air-bleed. For instance, at full throttle, a taper-pointed valve with'a small hole in the point can be made to seat in the air-bleed passage, thus reducing the supply of air and giving a richer mixture for high power. In fact, it then has an action somewhat resembling a power jet.

Three of the illustrations given last week show the

action of the Stromberg special IJX-type pump carburetter in which an accelerating charge is forced to the cylinders immediately the throttle is opened.

' A carburetter which has proved exceedingly popular for some years is the Solex, marketed by Solex, Ltd., 223-231, Marylebone Road, London, N.W.1. The M type which is the latest—is, broadly speaking, identi

cal with earlier models. It is only In detail that differences are discernible. In this instrument, the air Supply is constant and the mixture correction is obtained by the employment of a submerged jet having a calibrated orifice below the normal petrol level. Two air passages, also accurately calibrated and termed diffuser ,holes, ensure that the central channel of the jet is denuded of surplus petrol immediately the depression in the choke tube attains a figure equivalent to the head of petrol in the float chamber, i.e., at the lowest ordinary speeds at which the engine will run. If there were no holes, the suction of the engine would merely increase the flow of petrol directly with the speed of the engine; if the holes -Were too large, fuel would only pass until the charge of petrol above their level was exhausted, after which the supply would remain constant, regardless of engine speed.

It is claimed that, correctly adjusted, there is no sign of flat spots. A particularly good point about the Solex instrument is its remarkable accessibility. The removal of one large screw enables the float chamber, together with its float and two jets, to be withdrawn, leaving the body, of the instrument fixed to the cylinder block.