AN AMERICAN ENGINE FOR LIGHT CHASSIS.

Page 9

Page 10

If you've noticed an error in this article please click here to report it so we can fix it.

Details of the Latest Continental Power Unit for Fast Vehicles and the Lavine Steering Gear.

DURING a recent visit to the premises of the Automotive Products Co., of 3, Berners Street, London, W.1, we were afforded an Opportunity of examining the latest Continental power unit, which is suitable for vehicles of from 25 cwt. to ,30 eat. loadcarrying capacity designed for high-speed woilc, or for 2-ton vehicles built for ordinary commercial purposes.

The 'latest engine is the Red Seal J4 type, and is a very fine exaMple of American design: Continental engines have always borne a very good name for their high power output, economy and reliability.

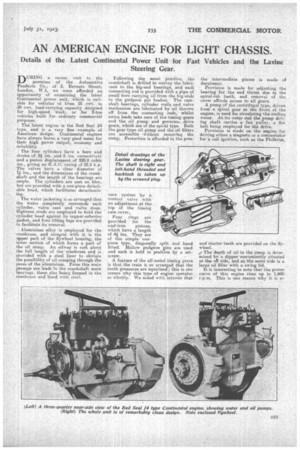

The "four cylinders have a bore and stroke of 3i iris. and 5 ins. resoectively and a piston displacement of 220.8 cubic ins., giving an R.A.C. rating of22.5 h.p. The valves have a clear diameter of ins., and the dimensions of the crankshaft and the length of the bearings are ample. The cylinders are cast en bloc, hut are provided with a one-piece detiichable head, which facilitates decarbonizing.

The water jacketing is so arranged that the water completely surrounds each cylinder, valve seat and valve stem. Kighteen studs are employed to hold the cylinder head against its copper-asbestos gasket, and four lifting lugs are provided to facilitate its "removal.

Aluminium alloy is employed, for the crankcase, and integral with it is the upper part of the flywheel housing, the lower section of which forms a part of the oil sump. An °away is cast along the full length of the crankcase and is Provided with a steel liner to obviate the possibility of oil creeping through the pores of the aluminium. From this main passage are leads to the crankshaft main bearings, these also being formed in the crankcase and lined with steel, Following the usual practice, the crankshaft is drilled to convey the lubricant to the big-end bearings, and each connecting rod is provided with a pipe of small bore carrying oil from the big-ends to the gudgeon pin bushes. The camshaft bearings, cylinder walls and valve mechanism are lubricated by oil thrown off from the connecting rods,' whilst extra leads take care of the timing gears and the oil pump and governor, drive gears, which are of the spiral type. Both the gear type oil pump and the oil filters are accessible without removing the sump. Protection is afforded to the pres sure system by a control valve with an adjustment,at the top of the timing case cover.

Four rings are provided for the east-iron pistons, which have a length of 4k ins. They are of the simple onepiece type, diagonally split and hand fitted. Hollow gudgeon pins are used and each is held in position by a setscrew.

A feature of the all-metal timing gears is that the train is so arranged that the tooth pressures are equalized; this is one reason why this type of engine operates so silently. We noted with interest, that, the intermediate pinion is made of duralunain.

Provision is made for adjusting the bearing for the end thrust due to the spiral-cut teeth, and removal of the cover affords access to all gears.

A pump of the centrifugal type, driven from a spiral gear at the front of the i engine, s used for circulating the cooling water. At its outer end the pump driving shaft carries a fan pulley, a flat belt being employed for the drive.

Provision is made on the engine for driving either a magneto or a commutator for a coil ignition, such as the Philbrim, and starter teeth are provided on the flywheel.

The depth of oil in the sump is determined by a dipper conveniently situated at the off side, and at the same side is a large oil filler with a swing lid. It is interesting to note that the power curve of this engine rises up to 1,600 r.p.m. This is One reason why it is so eminently suitable for speed-wagon work. The Automotive Products CO., apart from being sole representatives in the British'Isles for the makers of these en. glues, also have concessions for Borg and Beck clutches, Detroit gearboxes, Timken axles, Mather springs, and Lavine steering gears.

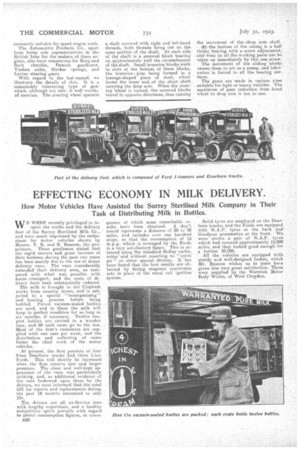

With regard to the last-named, we illustrate the details• of this. It is a remarkably interesting type of -gen.'. which, although net new, is well worthy of mention. The steering wheel operates a shaft screwed with right and left-hand threads, both threads being cut on the. same portion of the shaft. At each side of the shaft is a screwed block bearing: on approximately half the crournfereric.e of the abaft. Small trunnion blocks .work in slots at the bottom of these blocks, the trunnion, pins being formedin a lozenge-shaped piece of steel, which forms the inner end,of• the short shaft carrying the drop arm. When the steering wheel is turned, the screwed blocks travel in opposite directions, thus causing the movement of the-drop arm shaft. At..,the -bottom of the casing is a bah thitist bearing with a screw adjustment, i and Wear 'on all theworking parts can be taken up immediately by this one screw. The movement of the sliding-blocks causes them to act as a pump, and lubrication is freed to all the bearing sur

faces.. . • The gears are made in various sizes suitable for light or heavy vehicles. The maximum of gear reduction from hand wheel to drop anti is ten to one.