So much depends on the entrance

Page 56

Page 57

If you've noticed an error in this article please click here to report it so we can fix it.

The most awkward area to deal with is the shop which is longer than it is wide and which has the only door at one of the narrow ends

• Most operators who carry out their own maintenance would agree that there has to be some law or other which says that no matter how much space you have it is never enough. Certainly it often seems that way, usually when there is an urgent job to be done on a vehicle. Either there is no room to get it in the workshop or, more likely, there would be room but there are two other vehicles in the way, and the most awkward one is up on axle stands with its brakes dismantled.

Usually, the blame for this sort of situation is laid at the door of the fitter who brought the offending and obstructing vehicle into the workshop. He is blamed for being thoughtless. He knew the vehicle was going to be immobile for several days, so why didn't he put it somewhere other vehicles could get in and out more easily?

Possibly the answer is that he didn't think about it, but it may have been that there was nowhere else in the workshop for him to put it. Either way, the fitter is not really the person to blame. There should have been guidelines — flexible if you like, but still guidelines — laid down about where vehicles should be put in a workshop before they are put up on stands or have major components taken off and, if possible, an area of the workshop for quick turnround schedule servicing or minor running repairs which is separate from the part used for longer-term work.

If you are fortunate enough to be building a workshop from scratch, then a lot of this planning can be done on paper before even the foundations are dug. It might sound a bit like playing with toys, but whether you are planning for a new building or thinking about modifying an existing one, a few diecast models laid out on a plan of your workshop, all to the same scale, makes it much easier to visualise what the finished job will be

It is easier to have good ideas about how to use the space both inside and around the workshop, to better advantage when you are looking at models on a plan than it is when you are walking round the site.

Probably the thing which more than

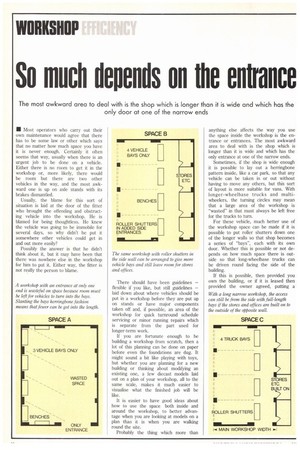

anything else affects the way you use the space inside the workshop is the entrance or entrances. The most awkward area to deal with is the shop which is longer than it is wide and which has the only entrance at one of the narrow ends.

Sometimes, if the shop is wide enough it is possible to lay out a herringbone pattern inside, like a car park, so that any vehicle can be taken in or out without having to move any others, but this sort of layout is more suitable for vans. With longer-wheelbase trucks and multiwheelers, the turning circles may mean that a large area of the workshop is "wasted" in that must always be left free for the trucks to turn.

For these vehicle, much better use of the workshop space can be made if it is possible to put roller shutters down one of the longer walls so that shop becomes a series of "bays", each with its own door. Whether this is possible or not depends on how much space there is outside so that long-wheelbase trucks can be driven round facing the side of the building.

If this is possible, then provided you own the budding, or if it is leased then provided the owner agreed, putting a With a long narrow workshop, the access can still be from the side with full-length bays if the stores and offices are built on to the outside of the opposite wall. row of openings in the side is often nothing like as difficult a job as it may seem. There will be some sort of piers or supports along the wall, and if these are reinforced it is usually possible to put lintels across the tops to take roller shutters.

There are two essentials. The first is to get an architect or a structural building engineer to have a look and stress out the loads. The second is to inquire from the local council whether or not planning permission is necessary. It may or may not be required depending on the building, the area and possibly the local bylaws. If it is necessary, then make sure you apply and get approval before any work starts.

Side entrance

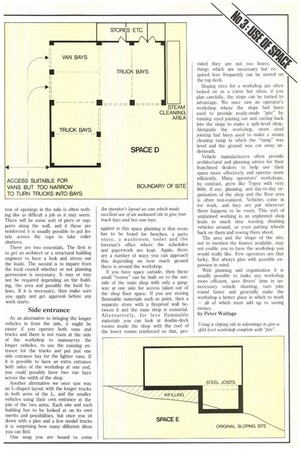

As an alternative to bringing the longer vehicles in from the side, it might be easier if you operate both vans and trucks and there is not room at the side of the workshop to manouevre the longer vehicles, to use the existing entrance for the trucks and put just one side entrance bay for the lighter vans. If it is possible to have an extra entrance both sides of the workshop at one end, you could possibly have two van bays across the width of the shop.

Another alternative we once saw was an L-shaped layout with the longer trucks in both arms of the L, and the smaller vehicles using their own entrance at the join of the two arms. Each site and each building has to be looked at on its own merits and possibilities, but once you sit down with a plan and a few model trucks it is surprising how many different ideas you can find.

One snag you are bound to come An operator's layout we saw which made excellent use of an awkward site to give four truck bays and two van bays.

against in this space planning is that room has to be found for benches, a parts store, a washroom, toilet and the foreman's office where the schedules and paperwork are kept. Again, there are a number of ways you can approach this depending on how much ground there is around the workshop.

If you have space outside, then these small "rooms" can be built on to the outside of the main shop with only a gangway at one side for access taken out of the shop floor space. If you are storing flammable materials such as paint, then a separate store with a fireproof wall between it and the main shop is essential. Alternatively, for less flammable materials you can look at double-deck rooms inside the shop with the roof of the lower rooms reinforced so that, pro vided they are not too heavy, things which are necessary but required less frequently can be stored on the top deck.

Sloping sites for a workshop are often looked on as a curse but often, if you plan carefully, the slope can be turned to advantage. We once saw an operator's workshop where the slope had been used to provide ready-made "pits" by running steel joisting out and cutting back into the slope to make a split-level shop. Alongside the workshop, more steel joisting had been used to make a steam cleaning ramp in which the "ramp" was level and the ground was cut away underneath.

Vehicle manufacturers often provide architectural and planning advice for their franchised dealers to help use their space more effectively and operate more efficiently. Many operators' workshops, by contrast, grew like Topsy with very little, if any, planning, and day-to-day organisation of the shop and the floor area is often non-existent. Vehicles come in for work, and they are put wherever there happens to be room. This sort of unplanned working in an unplanned shop leads to much time wasting shunting vehicles around, or even putting wheels back on them and towing them about.

The area and the shape of the site, not to mention the finance available, may not enable you to have the workshop you would really like. Few operators are that lucky. But always plan with possible expansion in mind.

With planning and organisation it is usually possible to make any workshop more efficient, save fitters' time in unnecessary vehicle shunting, turn jobs round faster and generally make the workshop a better place in which to work — all of which must add up to saving money.

by Peter Wallage