A NEW 30-CWT. CHASSIS 01•1 A LONDON WORKS.

Page 54

Page 55

Page 56

Page 57

If you've noticed an error in this article please click here to report it so we can fix it.

Designed for Easy Maintenance and Product Combines )mical Operation, the Latest Talbot city with Strength.

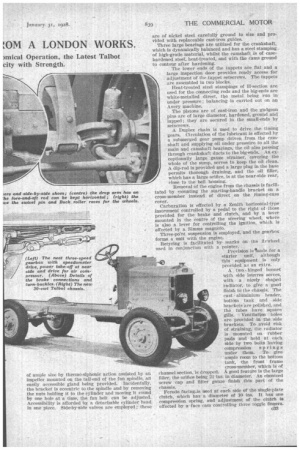

ABOLD bid for an important share in the market for the 30-cwt. chassis is about to be made by Clement Talbot, Ltd., Barlby Road, Ladbroke Grove,

London, W.10, This well-known company has, until now„ been mainly interested in the production of private ears (incidentally, of excellent repute); but it has had previous experience of commercial chassis design, and this is apparent in the new 30-cwt. model which we were kindly afforded an opportunity for inspecting last week.

It is, in our opinion, just the sort of chassis that is needed, a straightforward product at a reasonable price. The staff responsible for its design has always had in front of it the need for catering for the particularly arduous conditions dne to increasing traffic congestion in the cities and the higher running speeds which are practised hi less busy areas, and experience with other chassis has enabled the designers to give particular attention to certain points which have proved themselves to be potential sources of . weakness. .

The new vehicle has unusually large springs, a strong frame and front and rear axles of great strength ; also—and this is a point which will appeal to many—it is all-British.

The most important dimensions, etc., are :— Wheelbase, 10 ft. 6 ins.; overall length, 16 ft. 1 in.; behind driver's seat to end of frame, 8 ft. 6 ins.; frame height from ground, 2 ft. 4 ins. under load ; chassis weight complete, 1 ton 7 cwt. This permits the fitting of a strong tilt lorry body and well-protected cab on a vehicle weigh

ing complete 37 cwt., thus bringing it . easily within the L26 tax category. The petrol tank capacity

is 12 gallons ; cooling-water capacity, 6 gallons ; gear ratios, top, direct; second, 2.25 to 1; first, 4.8 to 1; reverse, 6.0 to 1; standard back axle ratio, 7 to 1; engine, 19.6 h.p. R.A.C. rating, 89 mm. bore and 120 mm. stroke; capacity, 2,986 c.c. In a short test we found this engine very lively. The price of this chassis, with 33-in. by 5-in. pneumatics at the front and 32-in, by 6-in, single pneumatics at the rear, will be £340, which will include a spare wheel with 33-in, by 5-in. tyre and equipment as stated.

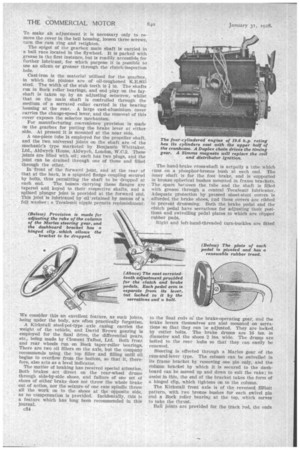

We will now deal with the general details, etc., of the chassis, commencing with the engine. This has four cylinders cast in one with the upper 'half of the crankcase. The cooling water is circulated through passages of ample size by therino-siphonic action assisted by an impeller mounted on the tail-end of the fan spindle, an easily accessible gland being provided. Incidentally, the bracket is eccentric to the spindle and by removing the nuts holding it to the cylinder and moving it round by one hole at a time, the fan belt can be adjusted. Accessibility is afforded by a detachable cylinder head in one piece. Side-by-side valves are employed ;• these are of nickel steel carefullY ground to size and provided with replaceable cast-iron guides.

Three large bearings are utilized for the crankshaft, which is dynamically balanced and has a steel stamping of high-grade. material, whilst the camshaft is of casehardened steel, heat-treated, and with the cams ground to contour after hardening.

The lower ends ef the tappets are flat and a large inspection door provides ready access for . adjustment of the tappet setscrews. The tappets are assembled in two blocks.

Heat-treated steel stampings of H-section are used for the connecting rods and the big-ends are white-metalled direct, the metal being run in under pressure ; balancing is carried out on an Avery machine.

The pistons are of east-iron and the gudgeon pins are of large diameter, hardened, ground and lapped ; they are secured in the small-ends by setscrews.

A Duplex chain is used to drive the timing gears. Circulation of the lubricant is effected by a submerged gear pump driven from the camshaft and supplying oil under pressure to all the main and camshaft bearings, the oil also passing • through crankshaft ducts to the big-ends. An exceptionally large gauze strainer, covering the whole of the sump, serves to keep the oil clean. A dip-rod is provided and a large plug in the base • permits thorough draining, and the oil filler, which has a large orifice, is at the near-side rear, close to the bell housing.

Removal of the engine from the chassis is faciIi, tated by mounting the starting-handle bracket on a cross-member instead of direct on the timingease cover.

Carburation is effected by a Zenith-horizontal-type instrument controlled by a pedal to the right of those provided for the brake and clutch, and by a lever mounted in the centre of the steering wheel, where is also a lever for controlling the ignition, which is effected by a Simms magneto.

Three-pent suspension is employed, and the gearbox forms a unit with the engine. Retyring is facilitated by marks on • the. flywheel used in conjunction with a pointer. Provision istaade for a starter unit, although this equipment is only provided as an eXtra.

A two.hinged bonnet with side louvres serves, with a nicely shaped radiator, to eve a good finish to the chassis. The cast = aluminium header, bottom tank and • side brackets arepolished, and the tubes have square gills. Vehtilafipn holes are provided in the side brackets. To avoid tisk of Straining, the radiator is Mounted on rubber pads and held at each side by two bolts having compression springs under them. To give 'ample room to the bottom tank,' the front frame crossenember, which is of channel section, is dropped. A good feature is the large filler, the orifice being 1-2?,ins in diameter. An ebonized screw cap and filter gauze finish this part of the

chassis.

Ferodo facing.is Used at each side of the single-plate clutch, which has a diameter of 10 ins. It has one compression spring, and adjustment of the clutch is effected by a. face cam .controlling three toggle fingers.

To make an adjustment it is necessary only to remove the cover in the bell housing, loosen three screws, turn the cam ring and retighten.

The spigot of the gearbox main shaft is carried in a ball race located in the flywheel. It is packed with • grease in the first instance, but is readily accessible for further lubricant, for which purpose it is possible to use an oilcan or greaser through the clutch-inspection hole.

Cast-iron is the material utilized for the gearbox, in which the pinions are of oil-toughened K.E.805 steel. The width of the stub teeth is in. The shafts run in Bock roller bearings, and end play on the layshaft is taken up by an adjusting setscrew, whilst that on the main shaft is controlled through the medium of a serrated collar carried in the bearing housing at the rear. A large east-aluminium cover carries the change-speed lever, and the removal of this cover exposes the selector mechanism.

For manufacturing convenience provision is made on the gearbox for putting the brake lever at either side. At present it is mounted at the near side.

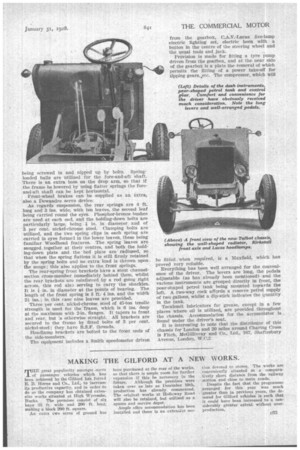

A one-piece tube is employed for the propeller shaft, and the two universal joints on the shaft are of the Mechanic's type marketed by Benjamin Whittaker, Ltd., Aldwych House, Aldwyeh, London, W.C.2. These joints are filled with oil; each has two plugs, and the joint can be drained through one of these and filled through the other. .

In front of the forward joint, and at the rear of that at the back, is a spigoted flange• coupling secured by bolts, thus' permitting the shaft to be dropped at each end. The bosses carrying these flanges are tapered and keyed to their respective shafts, and a spitted plunger joint is provided at the forward end. This joint is lubricated by oil'retained by means of a felt ,washer ; a Tecaletnit nipple permits replenishment.

We consider this an excellent feature, as such joints, being under the body, are often practically forgotten. A Kirkstall steel-pot-type axle easing carries the weight of the vehicle, and David Brown gearing is employed for the final drive, the differential gears, etc., being made by Clement Talbot, Ltd. Both front and rear wheels run on Bock taper-roller bearings. There are two oil fillers on the axle, but the company recommends using the top filler and filling until oil begins to overflow from the bottom, so that it, therefore, also acts as a level indicator.

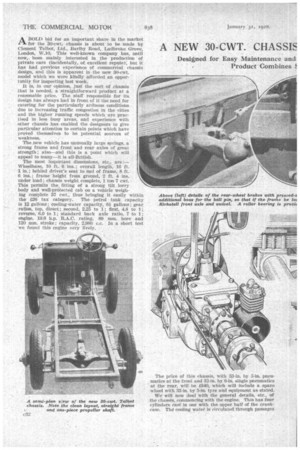

The matter of braking has received special attention.

• Both brakes act direct on the rear-wheel drums through side-by-side shoes, and failure of one set of shoes of either brake does not throw the whole brake out of action, nor the seizure of one cam spindle throw all the work on to the shoes at the opposite side, as no compensation is provided. Incidentally, this is a feature which has long been recommended in this journal.

c34 The hand-brake cross-shaft is actually a tube which runs on a phosphor-bronze bush at each end. The inner shaft is for' the foot brake, and is •supported in bronze spherical bushes mounted in frame brackets. The space between the tube and the shaft is filled with grease through a central Teealemit lubricator. Adequate protection by pressed sheet-steel covers is afforded. the brake shoes, end these covers are ribbed to prevent drumming. Both the brake pedal and the clutch pedal have serrations for adjusting their positions and swivelling pedal plates to which are clipped rubber pads.

Right and left-hand-threaded turn-buckles are fitted to the final rods o the brake-operating gear, and the brake levers themselves are alsd mounted on serrations so that they can be adjusted. They are locked by cotter bolts. The brake drums are 16 las, in diameter and the shoes 2 ins. wide. The drums are bolted to the rear hubs so that they can easily be renewed.

Steering is effected through a Merles gear of the cam-and-lever type. The column can be swivelled in its frame bracket by removing one pin only, and the column bracket by which it is secured to the dashboard can be moved up and down to suit the rake; to assist in this, the end of the bracket takes the form of a hinged clip, uhich tightens on to the column.

The Kirkstall front axle is of the reversed Elliott pattern, with two bronze bushes for each sWivel pin and a Bock roller bearing at the top, which serves to take the thrust.

Ball joints are provided for the track rod, the ends

being screwed in and nipped up by bolts. Springloaded balls are utilized for the fore-and-aft shaft. There is an extra boss on the drop arm, so that if the frame be lowered by using flatter springs the foreand-aft shaft can be kept horizontal. '

Front-wheel brakes can be supplied as an extra, also a Dewandre servo device.

As regards suspension, the rear springs are 4 it. long and 3 ins, wide; with ten leaves, the second leaf being carried round the eyes. Phosphor-bronze hushes are used at each end, and the holding-down bolts are

particularly large, being in. in diameter and of 3 per cent. nickel-chrome steel. Clamping bolts are utilized, and the two spring clips in each spring are carried in eyes formed in the lower leaves, these being familiar Woodhead features. The spring leaves are snugged together at their centres, and both the hold s

ine-down plate and the bed pla le are xa ed dius, so that when the spring flattens it is still firmly retained by the spring bolts and no extra load is thrown upon. the snugs; this also applies to the front springs.

The rear-spring front brackets have a stout channelsection cross-member immediately behind them, whilst the rear brackets are reinforced by a rod going right across, this rod also serving to carry the shackles. It is in. in diameter at the points of bearing. The length of the front spring is 3 ft. 4 ins, and the width 2i ins.; in this case nine leaves are provided.

Three per cent. nickel-chrome steel of 45-ton tensile strength is used for the frame, which is 6 ins, deep at the maximum with 2-in. flanges. It tapers to front and rear, but s otherwise straight. All brackets are secured to the frame by fitted bolts of 3 per cent. nickel-steel; they have B.S.F. threads.

Headlamp brackets are bolted to the front ends of the side-members.

The equipment includes a Smith speedometer driven

be fitted when required, is a Maxfield, which has proved very reliable. Everything has been well arranged for the convenience of the driver. The levers are long, the pedals adjustable (as has already been mentioned) and the various instruments are grouped directly in front, the pear-shaped petrol tank being mounted towards the left. A two-way cock affords a reserve petrol supply of two gallons, whilst a dip-stick indicates the quantity in the tank.

Tecalemit lubricators for grease, except in a few places where oil is utilized, are provided throughout the chassis. Accommodation for the accumulator is found under the driver's seat.

It is interesting to note that the distributor of this chassis for London and 20 miles around Charing Cross is Fitch, McGillivray and Co., Ltd., 167, Shaftesbury Avenue, London, W.C2