159. — Packing the Leyland Water Pump.

Page 34

Page 35

If you've noticed an error in this article please click here to report it so we can fix it.

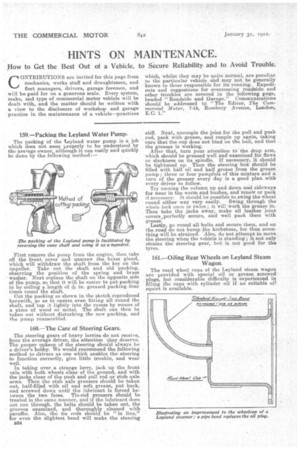

The packing of the Leyland water pump is a job which does not seem properly to he understood by the average owner, although it can easily and quickly be done by the following method:— First remove the pump from the engine, then take off the front cover and unscrew the brass gland, which will withdraw the shaft from the key on the impeller. Take out the shaft and old packing, observing the position of the spring and brass washer. Next replace the shaft on the opposite side of the pump, so that it will be easier to put packing in by coiling a length of in. greased packing four times round the shaft.

Cut the packing as shown in the sketch reproduced herewith, so as to ensure even fitting all round the shaft, and tap :t lightly into the recess by means of a piece of wood or metal. The shaft can then be taken out without disturbing the new packing, and the pump reassembled.

160.—The Care of Steering Gears.

The steering gears of heavy lorries, do not receive, from the average driver, the attention they deserve. The proper upkeep of the steering should always be a driver's hobby. We would recommend the following method to drivers as one which enables the steering to function correctly, give little trouble, and wear well.

In taking over a strange lorry, jack up the front axle with both wheels dear of the ground, and with the jacks clear of the push and pull rod or stub axle arms. Then the stub axle greasers should -be taken out, half-filled with oil and soft grease, put back, and screwed down until the lubricant is forced between the two faces. Tie-rod greasers should be treated in the same manner, and if the lubricant does not run through, the bolts should be taken out, the grooves examined, and thoroughly cleaned with paraffin. Also, the tie rods should be " in line," for even the slightest bend will make the steering

B34 stiff. Next, uncouple the joint for the pull and push rod, pack with grease, and couple up again, taking care that the cup does not bind on the ball, and that the greaser is working.

After that, turn your attention to the drop arm, which should be greased well and examined for flaws or slackness on its spindle. If necessary, it should be tightened up. Then the steering box should be filled with half oil and half grease from the grease pump; three or four pumpfuls of this mixture and a turn of the greaser every day is a good plan, with every driver to follow.

Try turning the column up and down and sideways for wear in the worm and bushes, andrenew or pack if necessary. It should be possible to swing the wheel round either way very easily. Swing through the whole lock once or twice; it will work the grease in. Then take the jacks away, make all leather joint covers,perfectly secure, and well pack them with grease. Lastly, go round all bolts and secure them, and on the road do not bump the kerbstone, for then something -will be strained. Also, do not attempt to move the steering when the vehicle is standing; it not only strains the steering gear, but is not good for the tyres.

161.—Oiling Rear Wheels_on Leyland Steam Wagon.

The road wheel caps of the Leyland steam wagon are provided with special oil or grease screwed• plugs, but considerable difficulty is experienced in filling the caps with cylinder oil if no suitable oil, squirt is available.

Our illustration .shows•a mining this difficulty, by piping bend; screwod

th screwed cap, this taking A cap can be fitted over the

simple method of overfitting a standard gas gas on the outside into the place of the oil plug. outer end of the bend in or der to prevent any oil from being lost, and if the wheels are turned so that the bend is vertical, it is a simple matter to fill the cap with oil from an ordinary oilcan or tin withouttwasting oil through overflowing.