The Exclusion of the Horse.

Page 7

Page 8

If you've noticed an error in this article please click here to report it so we can fix it.

Tramway Managers Prefer the Reliable Motor for Overhead Line Repairs.

Self-propelled tower wagons are, rapidly, coming into favour with engineers, and others, on the staffs of numerous corporations. This type of utility vehicle is, practically, indispensable where wires and standards have, periodically, to be inspected, or repaired. Not only are these wagons vastly superior, in point of speed, to those drawn by any other means, but they are, also, touch firmer when fully extended, owing to the weight of the chassis, and the absence of a restless animal.

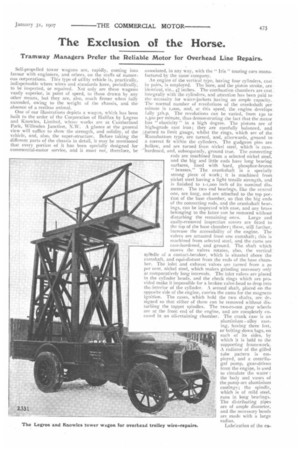

One of our illustrations depicts a wagon, which has been built to the order of the Corporation of Halifax by Legros and Knowles, Limited, whose works are at Cumberland Park, Willesden Junction, N.W. A glance at the general view will suffice to show the strength, and solidity, of the vehicle, and, also, the super-structure. Before taking the different parts of the chassis in detail, it may be mentioned that every portion of it has been specially designed for commercial-motor service, and it must not, therefore, be

associated, in any way, with the " Iris " touring cars manufactured by the same company.

An engine of the vertical type, having four cylinders, cast in pairs, is employed. The bore, and the piston stroke, are • idenrical, viz., 41 inches. The combustion chambers are cast integrally with the cylinders, and attention has been paid to the necessity for water-jackets having an ample capacity. The normal number of revolutions of the crankshaft per minute is x,000, and, at this speed, the engine develops fully 32h.p. The revolutions can be varied, from 150 to 1,500 per minute, thus demonstrating the fact that the motor has " elasticity " in a high degree. The pistons are of high-grade cast iron; they are carefully balanced, and turned to limit gauge, whilst the rings, -which are of the Ramsbottom type, are turned, and, afterwards, ground to a correct fit within the cylinders. The gudgeon pins are hollow, and are turned from nickel steel, which is case-hardened, and, subsequently, ground true. The connecting rods are machined from a selected nickel steel, and the big and little ends have long bearing .

surfaces, lined with hard, phosphor-bronze " brasses." The crankshaft iS a specially strong piece of work ; it is machined from nickel steel having a light tensile strength, and is finished to 1-1,000 inch of its nominal diameter. The two end bearings, like the central one, are long, and are attached to the top portion of the base chamber, so that the big ends of the connecting rods, and the crankshaft bearings, can be inspected with ease, and any brass belonging to the latter can be removed without

disturbing the remaining ones. Large and easily-removed inspection covers are fitted to the top of the base chamber; these, still further, increase the accessibility of the engine. The valves are actuated from one camshaft ; this is machined from selected steel, and the cams are case-hardened, and ground. The shaft which moves the valves rotates, also, the vertical: spiladle of a contact-breaker, which is situated above the camshaft, and equi-distant from the ends of the base chamber. The inlet and exhaust valves are turned from a 20 per cent, nickel steel, which makes grinding necessary only at comparatively long intervals. The inlet valves are placed in the cylinder heads, and the check rings which are provided make it impossible for a broken valve-head to drop into the•interior of the cylinder. A second shaft, placed on the opposite side of the engine, carries the cams for the magneto ignition. The cases, which hold the two shafts, are designed so that either of them can be removed without disturbing the tappet spindles. The two-to-one gear wheels are at the front end of the engine, and are completely encased in an oil-retaining chamber. The crank case is an aluminium alloy casting, having three feet, or bolting down lugs, on each of its sides, by which it is held to the supporting framework. A radiator of the gilled tube pattern is employed, and a centrifugalpump, gear-driven from the engine, is used to circulate the water : the body and vanes of the pump are aluminium castings; the spindle, which is of mild steel, runs in long bearings. The distributing pipes are of ample diameter, and the necessary bends are made with a large radius.

The L,egros and Knowles tower wAgon for overhead trolley wire-repairs. Lubrication of the en- gine is by a gear-driven oil pump, and sight-feeds, which can be adjusted to pass the required amount of oil, are in front of the driver. As in the water system, the oil-distributing tubes have no sharp bends. The oil reservoir contains sufficient for ten hours' continuous running.

Transmission is, primarily, 1:1T a leather-covered cone clutch having a large diameter; the angle of the cones is such that the starting of the vehicle is smooth, and without shock, and the clutch spring is mounted so that adjustment is easily made. A cardan shaft connects the clutch to the gears within the gear box. The universal joints arc heavy, and the pins are of steel, case-hardened and ground. The gear-wheels give four speed ratios forward, viz., 3, 7, 12, and 15 miles per hour, with the engine running at 1,000 revolutions per minute. The reverse is three miles per hour. The change-speed lever, working in a "gate," is placed to the driver's right-hand side, and the alterations of speed are made through the selector rods; the rods are so arranged that those commanding the idle gears are automatically locked. The gear wheels are machined from a specially selected nickel steel, of a high tensile strength, and are wide upon the tooth faces_ The gear shafts have flanges, machined from the solid, and the gear wheels are bolted to these. The gear teeth are involute, and are accurately formed upon a special gear-cutting machine tool, after which the wheels are deeply case-hardened. The gear shafts are of nickel steel; they are of large diameter, and run ill long plain phosphor-bronze bearings. The gear box is an aluminium-alloy casting, and has a three-point suspension, to eliminate cross-winding, or other strains. The box is made in two portions, and the upper half carries all the bearings, so that, by dropping the lower half, which, in reality, forms the oil well, it is an easy matter to inspect the condition of the gear wheels, or to adjust the brasses. A large lid, held down by thumb screws, can, also, be removed during adjustments, if required. The differential gear is carried within the main gear box ; it is of the bevel wheel and pinion type, and is enclosed in a steel box. The teeth of the pinions, and wheels, are cut in a special machine, and are hardened. The outer ends of the two hall shafts from the differential are provided with sprockets, and these carry the roller driving chains which drive the back wheels. This portion of the transmission has been so designed that the chains are short, and run at a comparatively slow speed, thus tending to make them last longer than would otherwise be the case.

The steering is of the irreversible type, and all parts are massive, whilst the bearings have a large wearing area. All the moving portions work in an oil-tight case of aluminium. The eyes and pins in the coupling rods are all of ample strength, and are hardened and ground, whilst the rake of the pillar is such that the driver is allowed plenty of knee room.

The importance of efficient brake power cannot be overestimated, and the vehicle under notice is well supnlied in this respect. A foot pedal operates upon an internally-faced drum, placed upon the differential shaft, and is equally powerful in action when the vehicle is running forwards or backwards. The hand brake is of the internal-expanding type, and acts within two drums carried on the driving wheels : this brake is compensated, and completely enclosed, so that all dust, and dirt, is excluded from the friction faces. Special aLlention has been given to the means for adjustment, and this can be done without taking off the dust cap from the drums.

The frame is built from pressed steel, with cross members of the same section as the side members, and, in addition, strong gussets are riveted to the angles formed by the cross members and main pieces. The springs are long; the back ones are held by shackles at both ends, whilst the front springs are attached by their forward ends to the dumb irons. The wheels are of the artillery pattern, and the spokes are of cleft oak, whilst the felloes are of winterfelled ash. The hubs have very long, plain, phosphorbronze bearings, which will wear indefinitely before they have to be renewed. The front wheels have a diameter of 2 feet io inches, and are shod with Hopkireon 4-inch, single, solid tires, whilst the back wheels, which correspond in size to the frnnt ones, are shod with Hopkinson twin, 5-inch, solid tires. Back and front axles are of a special quality of steel, combining toughness and great strength in a high degree. The steering arms are machined from nickel steel, and both these, and the journals upon the back wheels, are case-hardened and ground perfectly true.

Some of the principal dimensions of the wagon are as follows :—Over all length, 13 feet, 6 inches; length behind dashboard, 9 feet, mm inches; wheel base, 9 feet; and wheel track, 4 feet, 6 inches. The makers of these vehicles submit samples of all the material employed in their construction to severe tests, before it is used, and special grades of nickel steel enter into the design of the chassis wherever it is thought advisable to employ it. The vehicles are entirely British made, and are guaranteed for two years from the date when delivery of a chassis is made. The tower, on the vehicle which we illustrate, can be raised to 20 feet above the ground level, and, when fully closed, is about 14 feet high. The platform at the top of the structure is made to revolve, so that the workmencan put it at the angle best suited to the needs of the moment_ The windlass, by which the upper portion of the skeleton framework is extended, may be seen, between the ladder and one of the main uprights. 'rue handrails on the platform fold down flat when not in use.

The accessories which are sent out witn. each wagon include: an acetylene head lamp; three paraffin lamps, two side lamps, and one tail lamp; lifting jack; and a complete set of spanners, etc.