A delivery vehicle with a foully tail-lift is about as

Page 40

Page 41

If you've noticed an error in this article please click here to report it so we can fix it.

much use as a trailer without a tractor. Chris Graham raises some important maintenance issues.

If your business involves regular cargo drops the likelihood is that you rely on tail-lifts. But these are often over-used and under-serviced. When trouble strikes and the lift becomes disabled, the consequences can be severe with immovable loads, missed drop-slots and contracts jeopardised.

The answer is to prevent the problems occurring in the first place through regular and well organised maintenance.

Vic Martin, sales director of Rateliff Tail-lifts (tel: 01707 325571), says: "Tail-lifts come in many forms—column, cantilever, retractable, double-tier tuck-away. All have their own features and idiosyncracies, but the key to maintaining them all is a methodical approach.

'We have proved that if tail-lifts are serviced correctly, and at the specified intervals, then they are remarkably reliable and durable units. Some of our customers are running up to 250 lift cycles a day without problems, because their levels of maintenance are appropriate."

Service interval

Like most other vehicle-related devices, taillifts have a set service interval which is determined by how often they are used. Establishing this involves consulting the equipment supplier, but the importance of getting it right cannot be over-emphasised.

To simplify matters, Rateliff offers its customers a bespoke service contract package. This includes two, three or four services a year, plus an inspection and weight test The latter is something which all operators should consider.

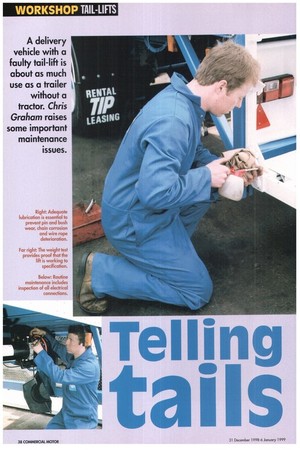

Martin says: "The weight test provides a safeguard for the operator in the event of an accident, because it provides proof that the lift was working to specification.

"This, essentially, is a straightforward operational test made using verified weights which are used to load the lift to its maximum, plus 25%. The system relief valve is then adjusted so that the load is lust' lifted. All users should build one of these tests into their maintenance programme, for their own peace of mind as much as anything else."

Bill Stanton, Ratcliff's customer services controller, sees first-hand the types of problem encountered by operators. He says: "Many users simply do not understand the maintenance requirements of a tail-lift, which is why we are keen to initiate contract maintenance schemes. Keeping up the servicing levels on a regular basis really does make all the difference." He adds: "One of the primary requirements, and the simplest, is adequate lubrication. Lack of it promotes premature pin and bush wear, chain corrosion and wire rope deterioration.

"Not only must lubrication be regular and thorough, it must also be undertaken with the correct products.

"Never be tempted to apply used engine oil or grease on chains. Correctly specified chain drive spray must be used. Grease will simply attract dirt and contamination to compound the problem. If the vehicle is regularly jet or steam-cleaned, lubrication should take place after every wash."

Straightforward neglect remains one of the most common causes of trouble. If standards are allowed to slide there will be more breakdowns. Much depends on the effectiveness of regular driver/operator inspections. Details such as missing control box covers, platform misalignment and poor operational performance should all be recognised and rectified early on_ Water ingress into the power pack—containing the hydraulic reservoir and pump, electric motor and a selection of control relays—will soon cause problems. Corrosion on wiring terminals and earth points will directly affect motor operation, often leading to premature brush wear.

Stanton says there are important safety issues to be considered too. "The tail-lift's load safety device must never be ignored. It is a ratchet cam system designed to halt the platform in the event of a chain breaking or a wire rope snapping," he says. "Sited within the column, it arrests the travel of the runner and pre vents the load being lost The effective operation of this safety device should be checked on a regular basis, and can be done easily by operators. It is a simple test and we are happy to advise on the exact procedure."

Descent speed

The descent speed of a tail-lift is governed by flow compensating valves and the correct operation of these must be monitored. Faults are treated by simply replacing the valve, which is a non-adjustable, spring-loaded plunger type.

The descent rate will always be quoted by the manufacturer—in Rateliff's case it should not exceed 150mm a second.

Stanton says a neglected tail-lift can be spotted easily. Most obvious is a lop-sided platform. He says: "If the platform hangs down from back to front, even without a load, this

During maintenance data is collected on each service operation.

signifies poor adjustment and makes the lift awkward and potentially dangerous to operate.

"There is an anti-tilt device which locks the platform in the horizontal position against the torsion bar support, but if this is not adjusted correctly problems will arise. The extra movement caused by a tilted platform will increase wear rates on the rest of the system. It is a simple 10-minute job to put things right."

But the ultimate king of the tail gate troubiers remains accident damage. Stanton says lifts are often crushed when vehicles reverse into loading bay docks. "This can cause all sorts of needless damage," he says. "Some drivers I have come across even use the tail-lift as a sort of bump stop!"

Impact damage may result in distorted or cracked runners, bowed platforms or broken torsion bars. The rubber buffers between the platform and the body can take a pounding too. These ensure the platform is held correctly when not in use, but get crushed by repeated dock impacts.

"Electric motor burn-out is another common problem," says Stanton. "On occasions a driver will forget to operate the isolation switch within the cab and, under certain circumstances, the motor will run until it overheats and becomes irreparably damaged."

Alternatively, overloading the lift itself— another frequent occurrence--*/*is likely to blow the pressure relief valve so that operation of the lift will be slowed. Although the motors are rugged, they are not designed to endure slow and prolonged use. Overheating results and the brushes within will start to "powder".

There is certainly much more to living with and maintaining a tail-lift than many realise. The key is to gain a thorough understanding of your equipment's operating procedures and maintenance requirements. Seek professional help if you are in any doubt.

Ratcliff runs training courses which are open to all, and publishes comprehensive servicing and trouble-shooting literature for its products.

So you ignore your tail-lift at your peril. The practical reality is that it should be regarded as another specialist component of your vehicle, and one which requires specific and methodical attention if potentially costly problems are to be avoided.